Carbon fiber fabric composite finished automobile framework and preparation method thereof

A technology of carbon fiber fabrics and composite materials, which is applied in the direction of motor vehicles, vehicle parts, upper structures, etc., can solve the problems of less occurrence, and achieve the effects of cost saving, material and weight reduction, and strong force bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to make those skilled in the art understand the present invention better, the present invention will be further described below in conjunction with specific embodiment:

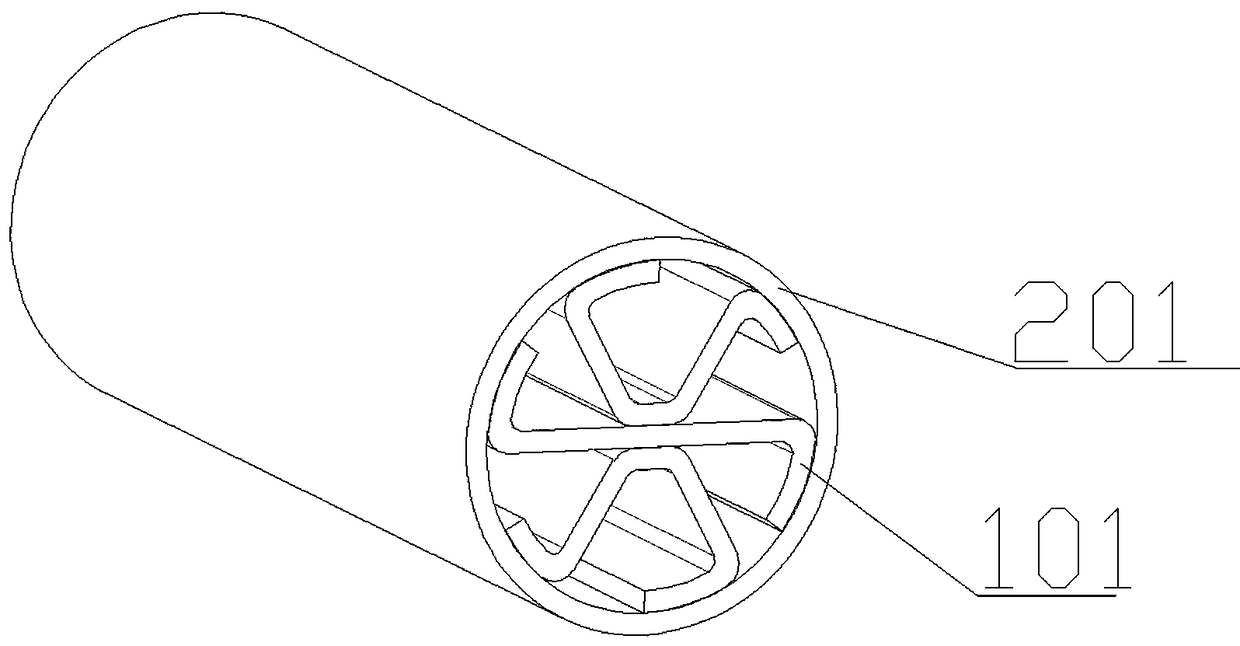

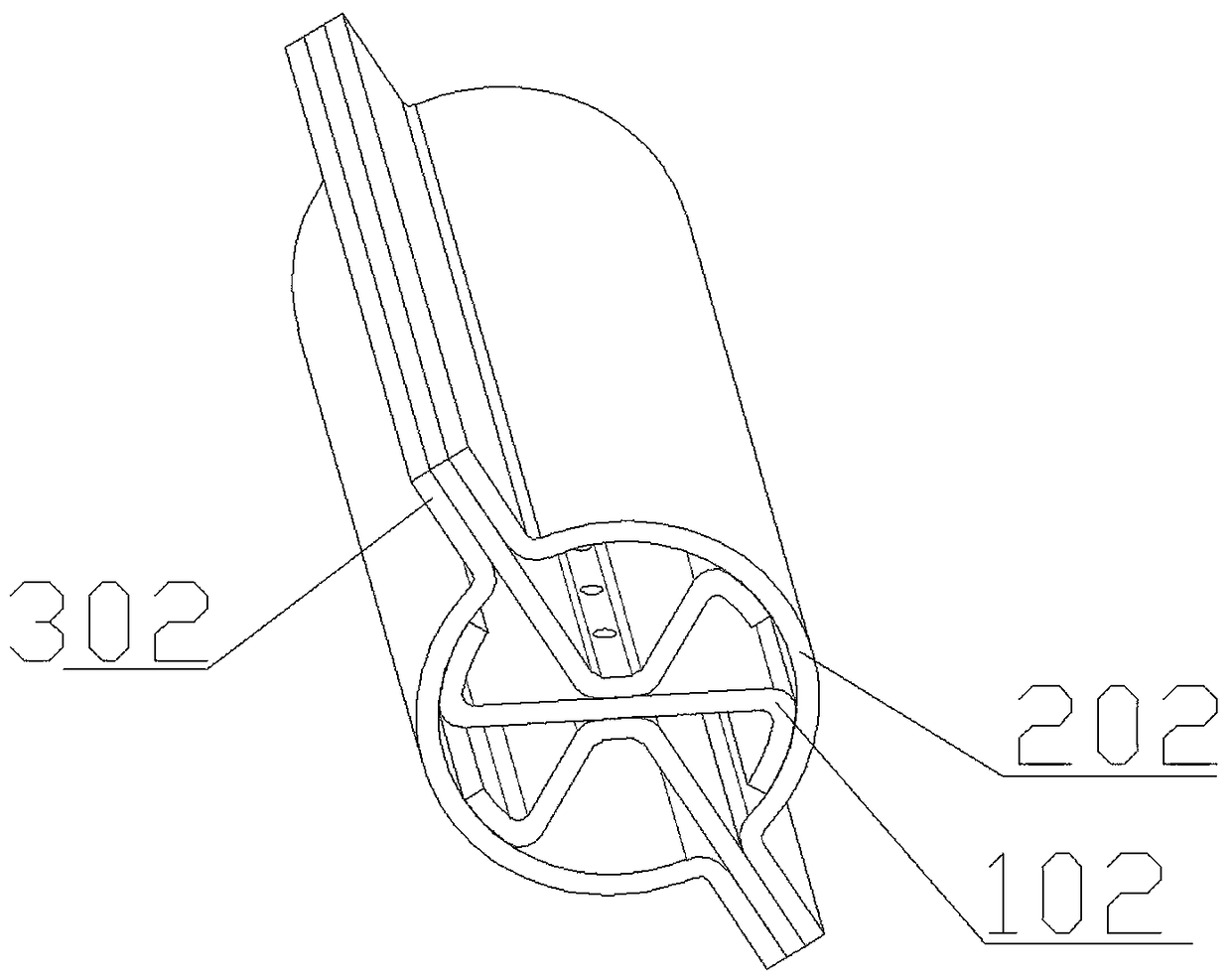

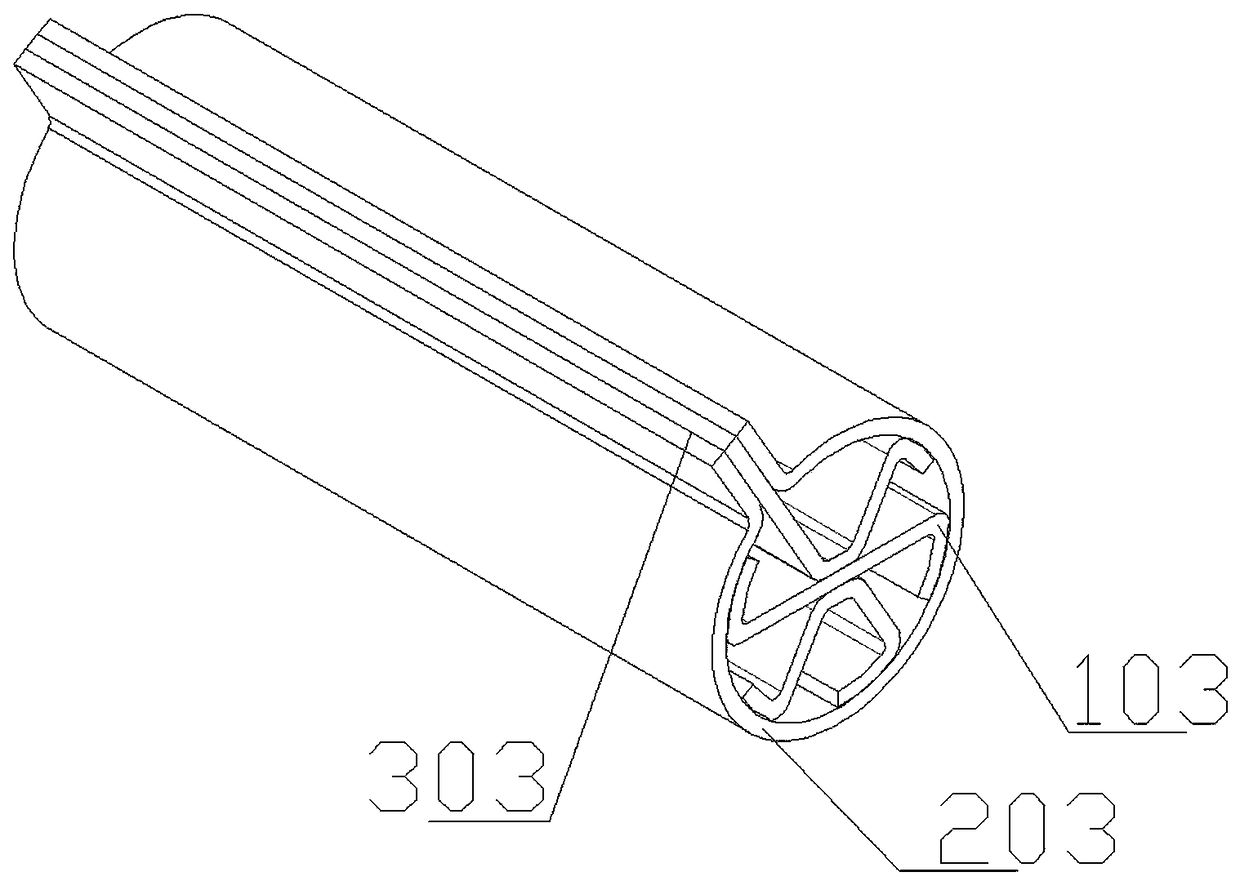

[0081] Such as Figure 1 to Figure 7 Shown, a kind of carbon fiber fabric composite material structural part, the outside of this structural part forms tubular, and described tubular structural part is the carbon fiber fabric composite material honeycomb pipe supported by carbon fiber fabric composite material; Wherein the carbon fiber fabric composite material comprises straight grain weaving and Twill weave, the carbon fiber fabric composite material is carbon fiber or glass fiber.

[0082] Such as Figure 1 to Figure 4 As shown, the fiber braid composite honeycomb pipe supported by the carbon fiber fabric composite material refers to the laminated carbon fiber fabric composite material stitched by sutures, which is radially supported by the sutures as the support axis to form a star-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com