Electroplating bath

A technology of electroplating tank and electroplating solution, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of uneven cathode electroplating, uneven left and right electroplating, etc., and achieve the goal of improving uneven electroplating, uniform current distribution, and optimizing electroplating parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

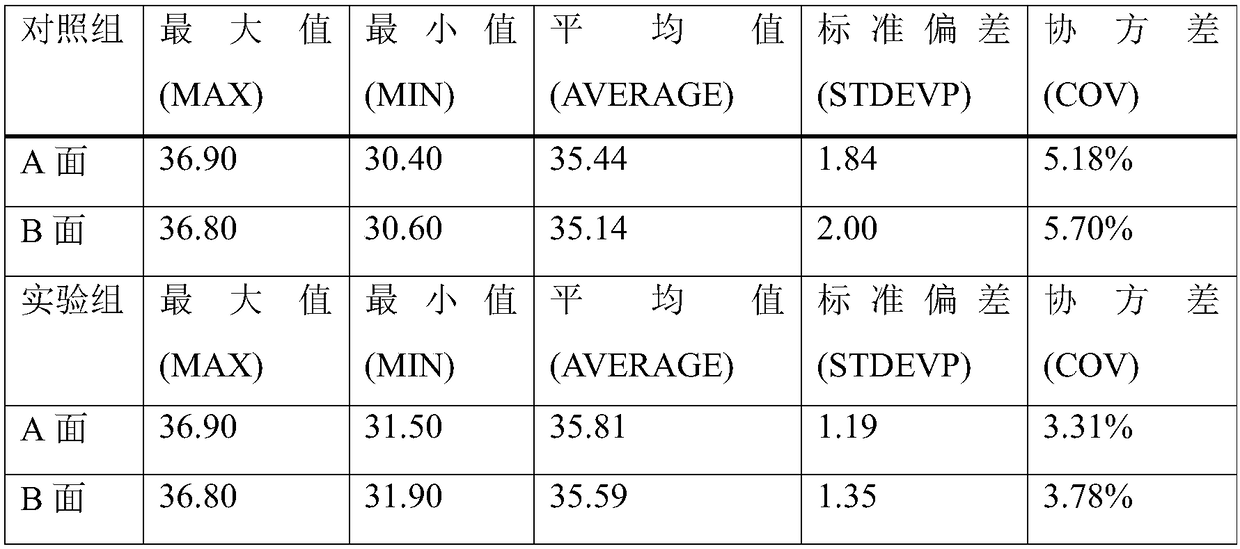

[0034] In this embodiment, the experimental group and the control group are designed to carry out comparative experiments. In the experimental group, the anodes on both sides swing back and forth to carry out circular motion. The anode is static, and the electroplating test is carried out under the same conditions as the experimental group. The experimental group and the control group are tested for uniformity after the electroplating is completed: use the CMI 700 copper thickness tester to test the surface copper thickness, and the electroplating uniformity adopts the method of uniformly taking points. The size of the electroplating plate is 160mm×110mm, and 150 points are evenly taken .

[0035] The experimental results are shown in Table 1:

[0036]

[0037] Table 1

[0038] The results show that the uniformity of copper thickness has been improved to a certain extent, the COV (Coefficient of Variance) value of side A has increased from 5.18% to 3.31%, the COV value of...

Embodiment 2

[0041] This example demonstrates the application potential of the new electroplating tank equipment in electroplating copper blind vias through electroplating blind via experiments.

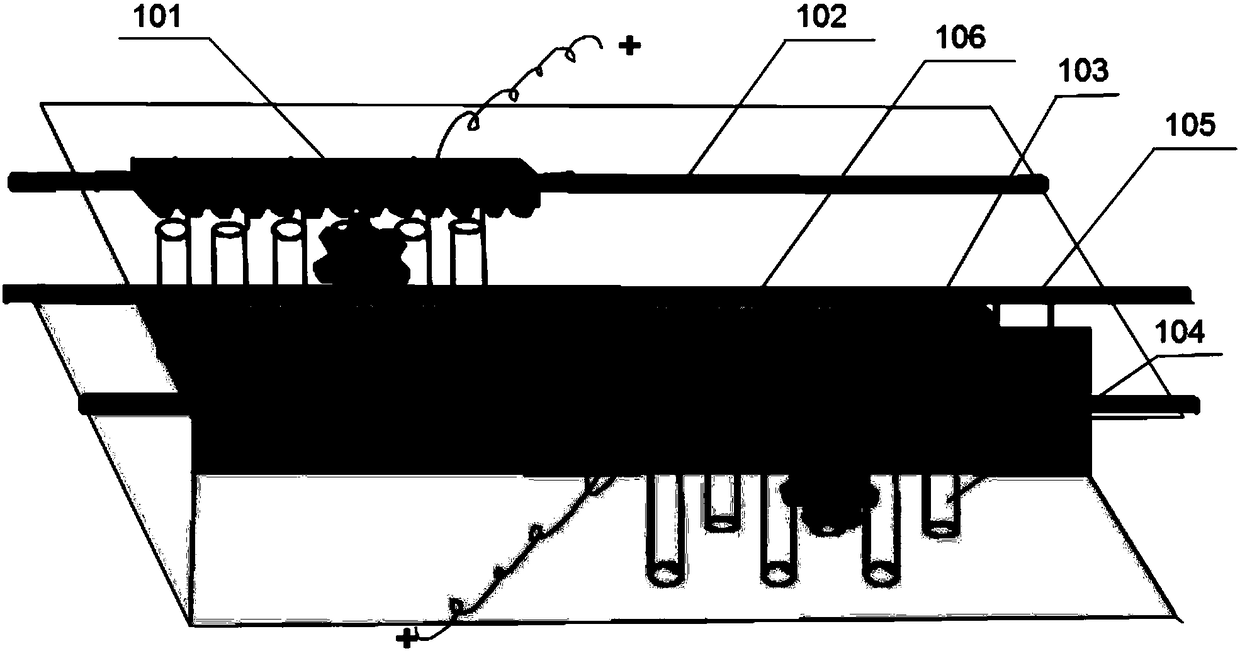

[0042] The design of this embodiment is to use the anode reciprocating swing mode to carry out cyclical movement. Add brightener, inhibitor and leveling agent to the bath of the electroplating tank in sequence. figure 1 The new type of electroplating tank shown is used for electroplating filling blind hole experiments. The hole diameter of the electroplating cathode blind hole plate is 85 μm, and the hole depth is 140 μm.

[0043] After the electroplating is completed, use a metallographic microscope to observe the blind hole slices, such as figure 2 For the metallographic diagram of blind hole slices, by adjusting the electroplating additives, the novel electroplating tank provided by the invention can also realize blind hole filling. The experimental results show that the new electroplating d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com