Wool fabric dyeing method

A dyeing method and wool technology, applied in the dyeing field, can solve the problems of uneven dyeing, effective cleaning of wool fabric without a cleaning device, etc., and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

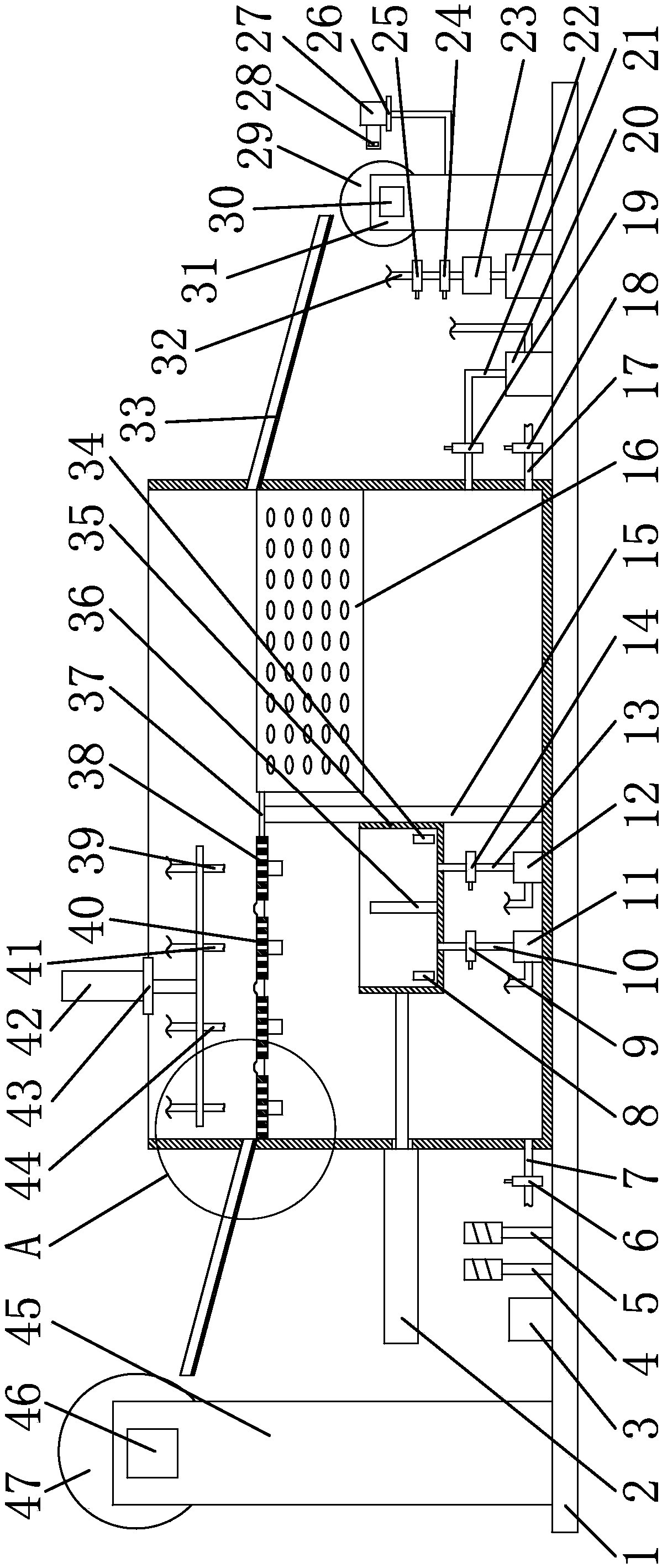

[0067] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0068] like Figure 1-Figure 5 Shown, the dyeing method of this woolen fabric, this dyeing method comprises the following steps:

[0069]S1. Inject distilled water into the dyeing machine at a bath ratio of 1:15-1:20, add wool fabric, run in a cycle for 5-10 minutes, add detergent 1-2g / L, add soda ash to adjust the pH value to 7.5-8.5, Raise the temperature to 70-90°C, keep it warm for 15-20min, then cool down to 50°C, and discharge the lotion; in this example, inject distilled water into the dyeing machine with a liquor ratio of 1:15, add wool fabric, and run in a cycle for 8 minutes. Add detergent 1.5g / L, add soda ash to adjust the pH value to 8.0, raise the temperature to 85°C, keep it warm for 17 minutes, then cool do...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap