Novel adjustable damping device

A damping device and adjustable technology, which is applied in the design features of springs/shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problems of human body or contact with things, affecting the service life of the product, and the impact of jumping frames. To achieve the effect of simplifying the structure, facilitating adjustment and reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

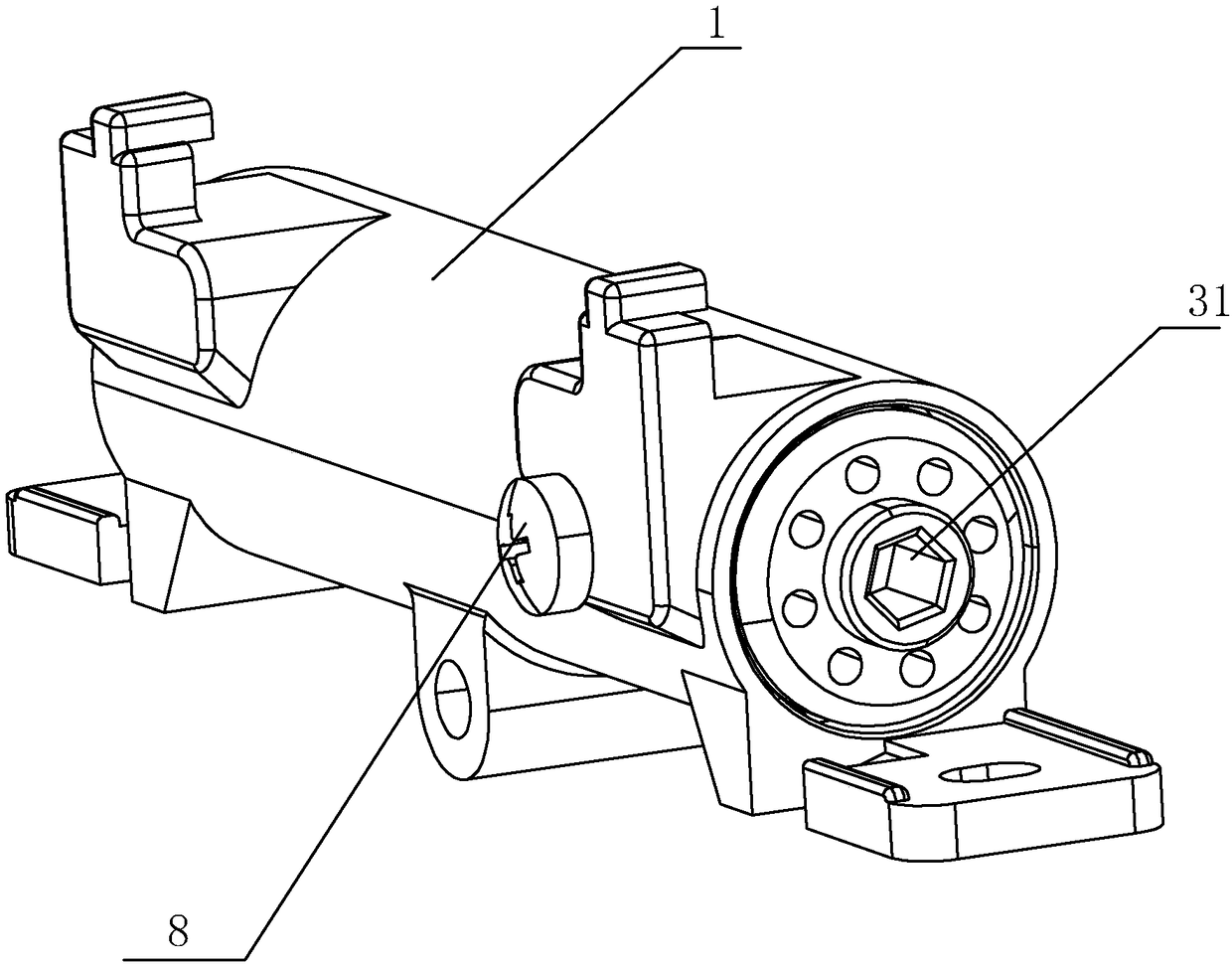

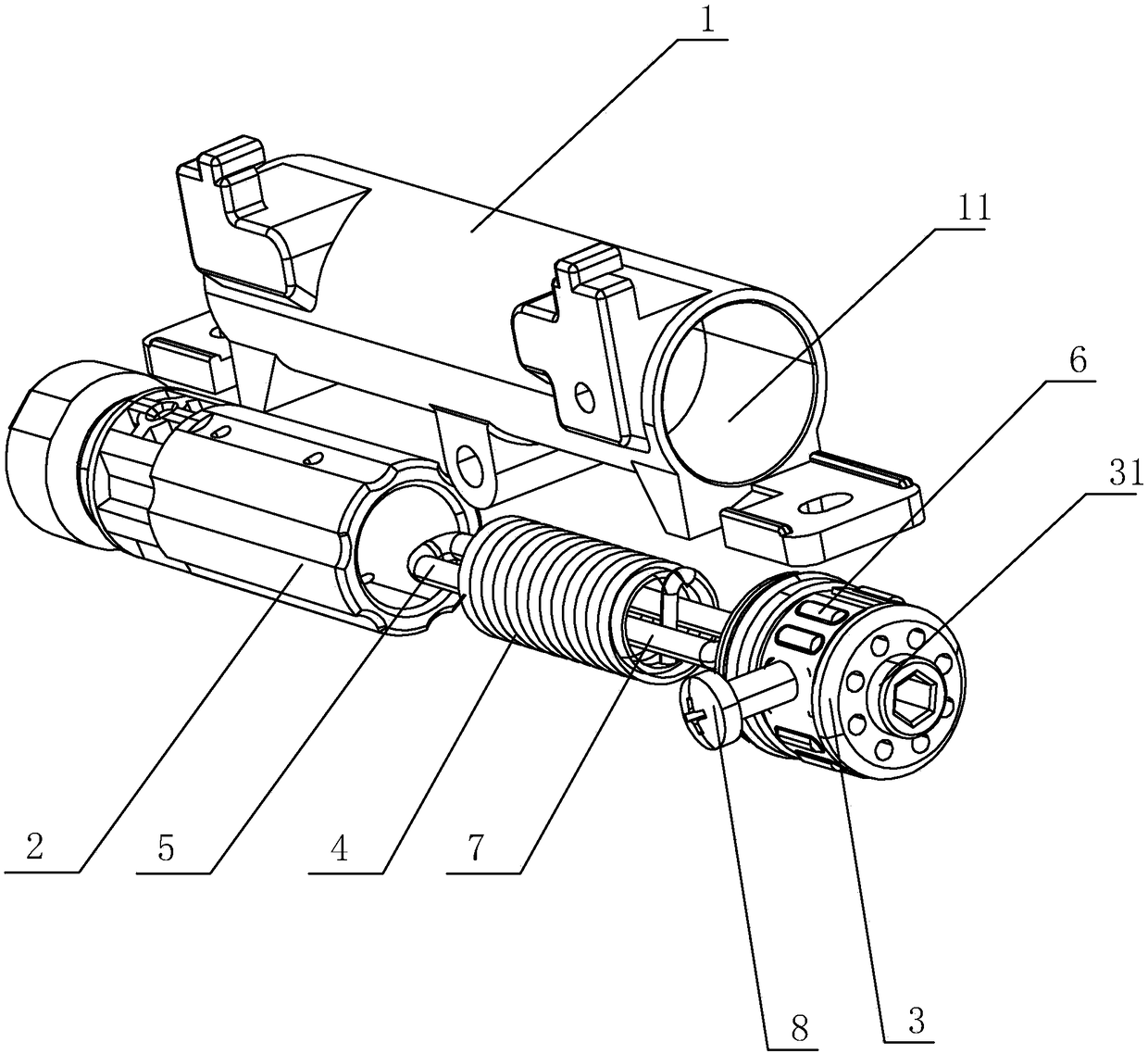

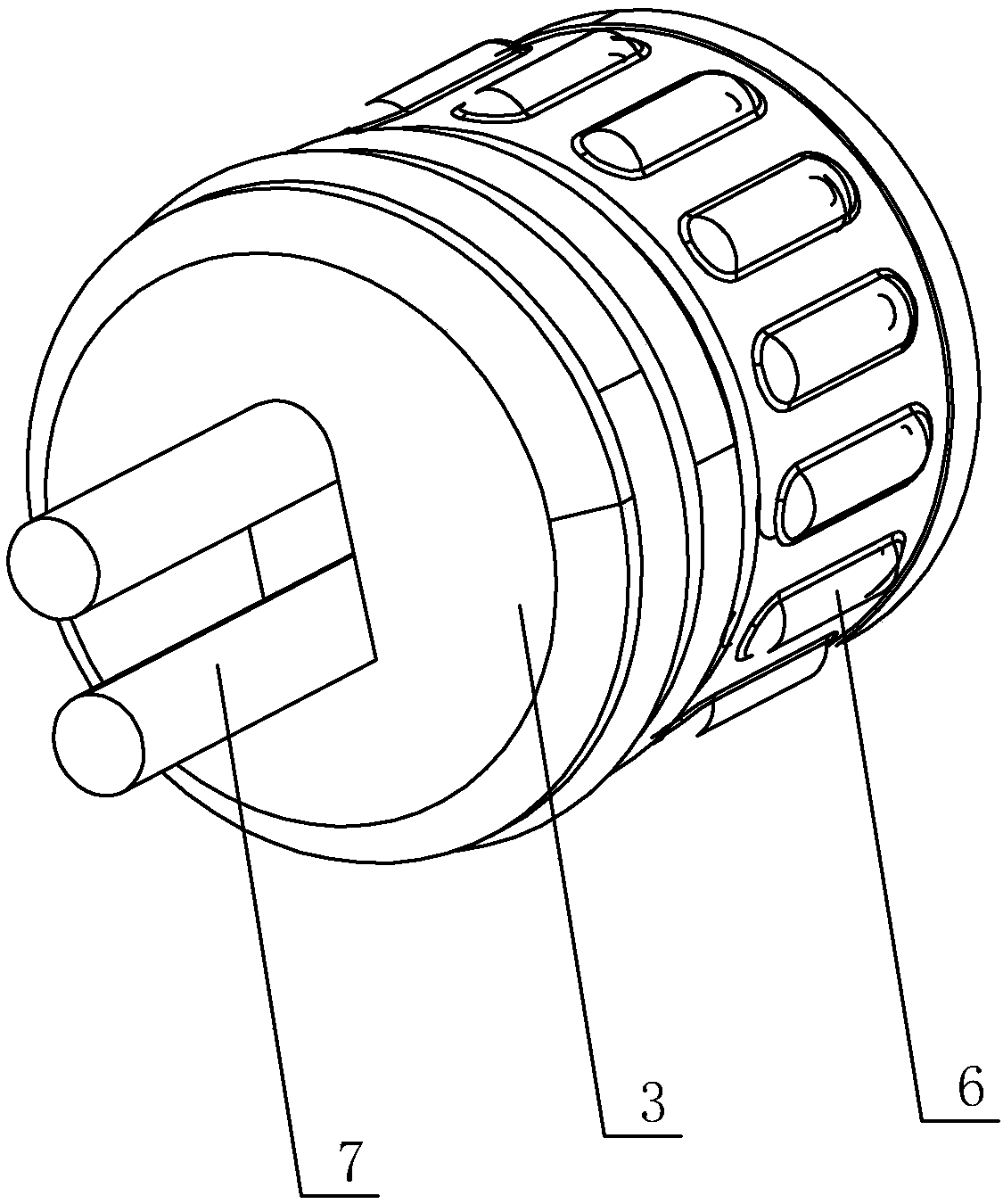

[0017] Refer to the attached Figure 1 to Figure 4 The embodiment of a novel adjustable damping device of the present invention will be further described in detail.

[0018] A novel adjustable damping device comprises a jump seat 1, a mounting hole 11 is arranged on the jump seat 1, a damping shaft 2 is arranged at one port of the mounting hole 11, and an adjusting shaft 3 is arranged at the other port, and the damping shaft A spring 4 is arranged between 2 and the adjusting shaft, and the mounting hole 11 is sealingly matched with the adjusting shaft 3 and the damping shaft 2 to form a cavity for filling damping oil, wherein the adjusting shaft 3 is sleeved with a sealing ring, and the adjusting shaft 3 The shaft 3 is sealed with the mounting hole 11 through a sealing ring, the damping shaft 2 is also sleeved with a sealing ring, and the damping shaft 2 is sealed with the mounting hole 11 through the sealing ring;

[0019] One end of the damping shaft 2 is inserted with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com