Machining process of vacuum pipe outer pipe

A processing technology, vacuum tube technology, applied in the field of vacuum tube outer tube processing technology, can solve problems such as complex process, reduced output, waste of water resources, etc., achieve the effect of shortening process steps, improving production efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

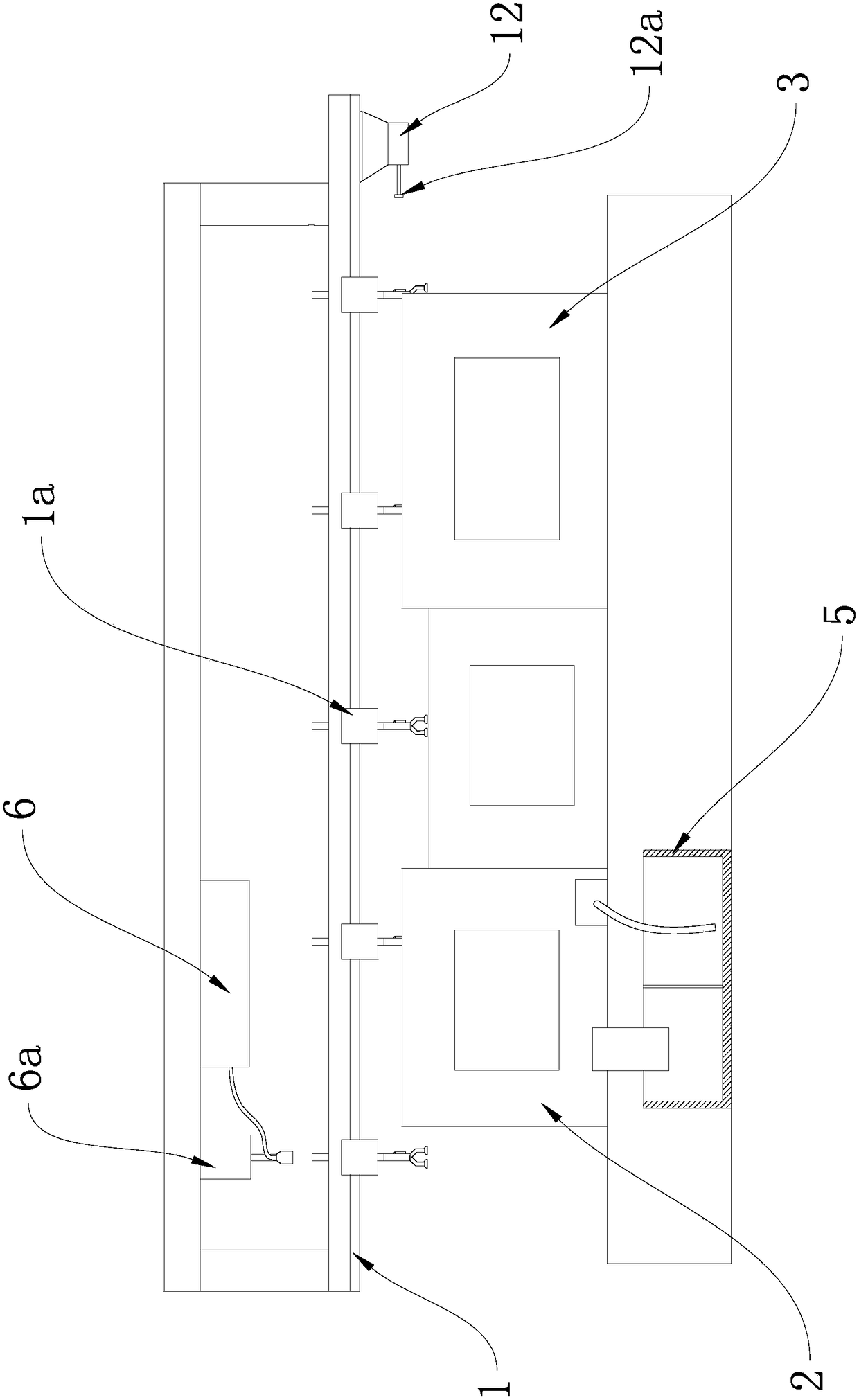

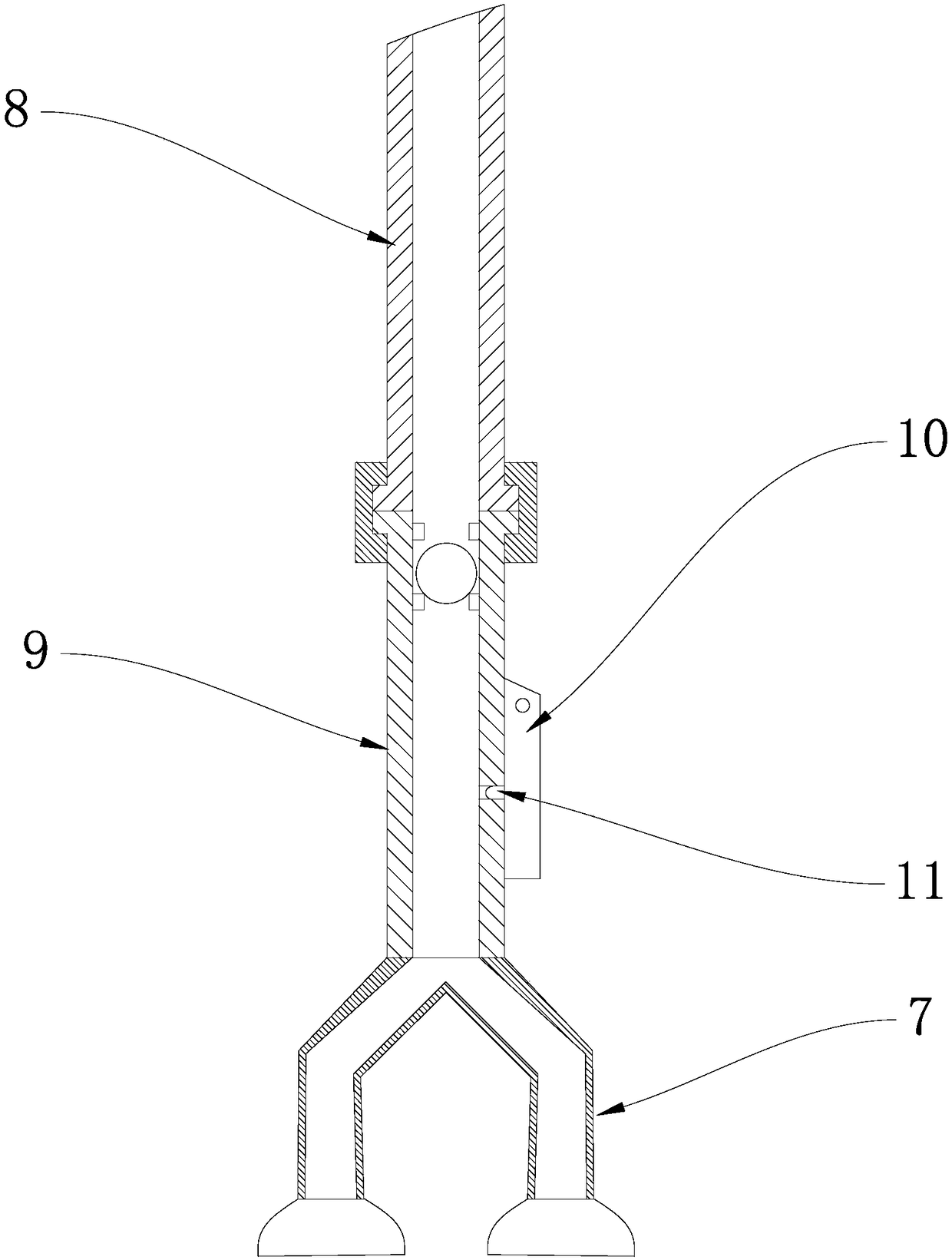

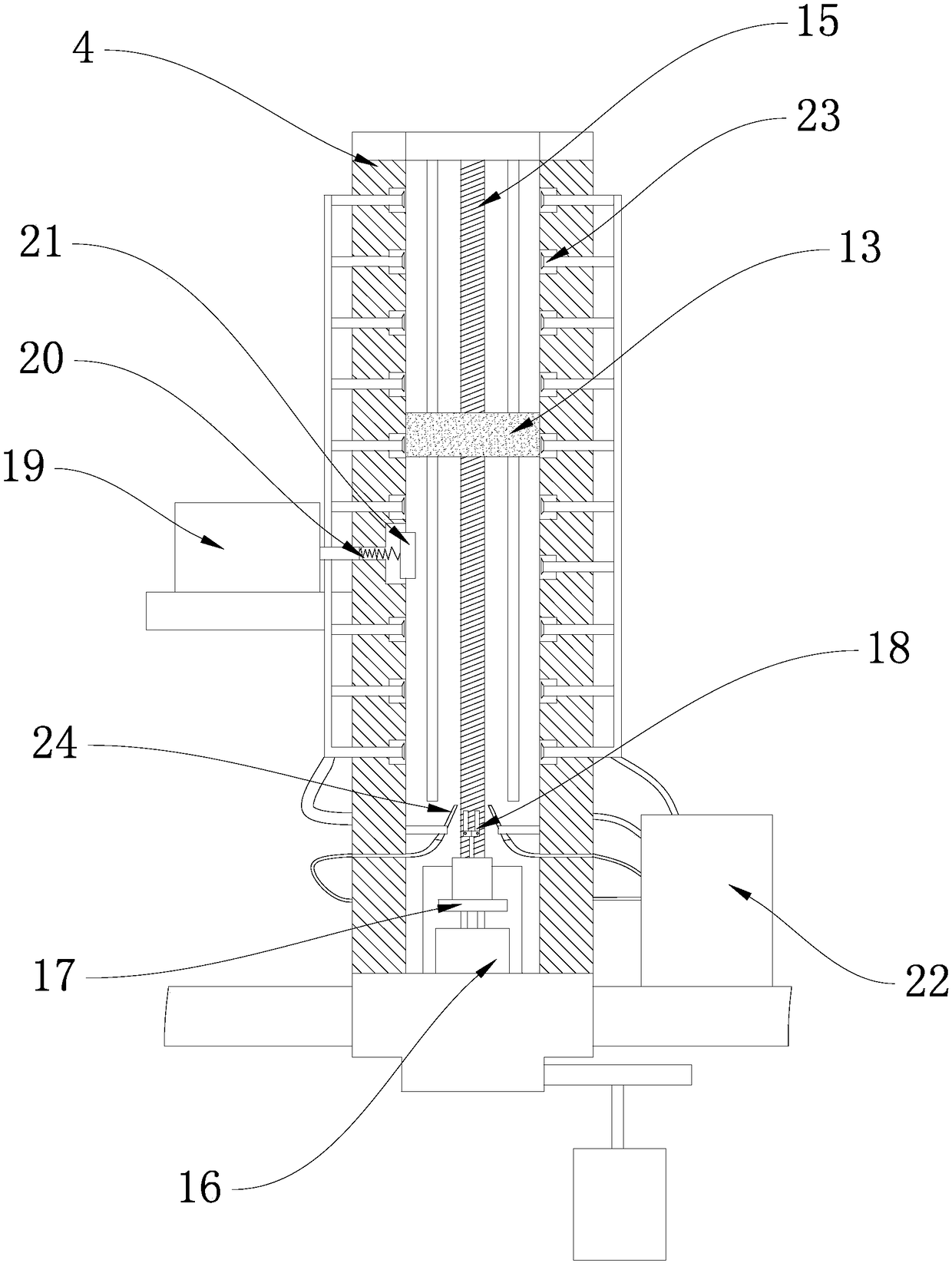

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0037] A process for processing an outer tube of a vacuum tube, the process comprising the following steps:

[0038] a. Outsourced raw materials: purchase existing quartz, borax, calcite, Glauber's salt, sodium hydroxide, nano-scale titanium powder and nano-scale barium carbonate as raw materials in the market;

[0039] b. Production of the outer tube: put quartz, borax, calcite, mirabilite, sodium hydroxide, and nano-scale titanium powder into the glass through melting and filtering, then put in nano-scale barium carbonate and stir evenly, and finally press the film to press the raw materials into glass Outer pipe semi-finished products and exhaust nozzles;

[0040] c. Round head firing: soften and melt the outer tube in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com