Nanocomposite material, manufacturing method and semiconductor device

A nanocomposite material and semiconductor technology, applied in the field of preparation methods, semiconductor devices, and nanocomposite materials, can solve the problems that cannot meet the requirements of nanocomposite materials for semiconductor devices, and the luminous performance needs to be improved, so as to meet the requirements of comprehensive performance and high-efficiency luminescence efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Embodiment 1: Preparation based on CdZnSeS / CdZnSeS quantum dots

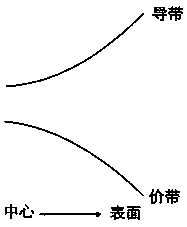

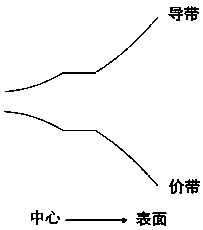

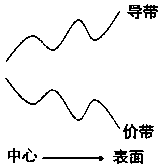

[0115] The precursors of cation Cd, cation Zn, anion Se and anion S are injected into the reaction system to form Cd y Zn 1-y Se b S 1-b Layer (where 0≤y≤1, 0≤b≤1); continue to inject the precursors of cation Cd, cation Zn, anion Se and anion S into the reaction system, in the above Cd y Zn 1-y Se b S 1-b Cd z Zn 1-z Se c S 1-c layer (where 0≤z≤1, and z is not equal to y, 0≤c≤1); under certain reaction conditions such as heating temperature and heating time, Cd and The exchange of Zn ions; because the migration distance of cations is limited and the probability of migration is smaller the farther the migration distance is, so it will be in Cd y Zn 1-y Se b S 1-b layer with Cdz Zn 1-z Se c S 1-c A graded alloy composition distribution of Cd content and Zn content is formed near the interface of the layer, that is, Cd x Zn 1-x Se a S 1-a , where 0≤x≤1, 0≤a≤1.

Embodiment 2

[0116] Embodiment 2: Preparation based on CdZnS / CdZnS quantum dots

[0117] The precursors of cation Cd, cation Zn and anion S are injected into the reaction system to form Cd y Zn 1-y S layer (where 0≤y≤1); continue to inject the precursor of cation Cd, the precursor of cation Zn and the precursor of anion S into the reaction system, the above Cd y Zn 1-y Cd formed on the surface of the S layer z Zn 1-z S layer (where 0≤z≤1, and z is not equal to y); under certain reaction conditions such as heating temperature and heating time, the exchange of Cd and Zn ions in the inner and outer nanocrystals (that is, the above two-layer compound) occurs ; Since the migration distance of cations is limited and the farther the migration distance is, the probability of migration is smaller, so the Cd y Zn 1-y S layer and Cd z Zn 1-z A gradual alloy composition distribution of Cd content and Zn content is formed near the interface of the S layer, that is, Cd x Zn 1-x S, where 0≤x≤1....

Embodiment 3

[0118] Embodiment 3: Preparation based on CdZnSe / CdZnSe quantum dots

[0119] The precursors of cation Cd, cation Zn and anion Se are injected into the reaction system first to form Cd y Zn 1-y Se layer (where 0≤y≤1); continue to inject the precursor of cation Cd, the precursor of cation Zn and the precursor of anion Se into the reaction system, the above Cd y Zn 1-y Cd formed on the surface of the Se layer z Zn 1-z Se layer (where 0≤z≤1, and z is not equal to y); under certain reaction conditions such as heating temperature and heating time, the exchange of Cd and Zn ions in the inner and outer nanocrystals occurs; due to the limited migration distance of cations And the farther the migration distance is, the smaller the probability of migration will be, so it will be in Cd y Zn 1-y Se layer and Cd z Zn 1-z A graded alloy composition distribution of Cd content and Zn content is formed near the interface of the Se layer, that is, Cd x Zn 1-x Se, where 0≤x≤1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com