A kind of nanocomposite material, preparation method and semiconductor device

A nano-composite material and device technology, applied in the field of quantum dots, can solve the problems that the requirements of nano-composite materials of semiconductor devices cannot be met, and the luminous performance needs to be improved, and achieve the effect of satisfying the comprehensive performance requirements and high luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Example 1: Preparation of quantum dots based on CdZnSeS / CdZnSeS

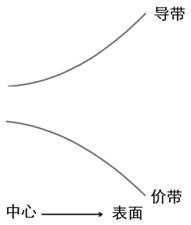

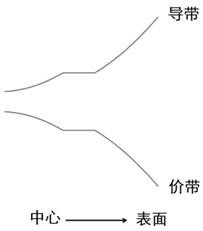

[0115] First, the precursor of cationic Cd, the precursor of cationic Zn, the precursor of anionic Se and the precursor of anionic S are injected into the reaction system to form Cd y Zn 1-y Se b S 1-b layer (where 0≤y≤1, 0≤b≤1); continue to inject the precursor of cation Cd, the precursor of cation Zn, the precursor of anion Se and the precursor of anion S into the reaction system, in the above Cd y Zn 1-y Se b S 1-b Cd is formed on the surface of the layer z Zn 1-z Se c S 1-c layer (where 0≤z≤1, and z is not equal to y, 0≤c≤1); under certain reaction conditions such as heating temperature and heating time, Cd in the inner and outer nanocrystals (that is, the above two-layer compounds) will interact with each other. The exchange of Zn ions; since the migration distance of cations is limited and the longer the migration distance, the less chance of migration, it will y Zn 1-y Se b S 1-b Laye...

Embodiment 2

[0116] Example 2: Preparation of quantum dots based on CdZnS / CdZnS

[0117] First, the precursor of cationic Cd, the precursor of cationic Zn and the precursor of anion S are injected into the reaction system to form Cd first. y Zn 1-y S layer (where 0≤y≤1); Continue to inject the precursor of cationic Cd, the precursor of cationic Zn and the precursor of anionic S into the reaction system, and the above-mentioned Cd y Zn 1-y Cd is formed on the surface of the S layer z Zn 1-z S layer (where 0≤z≤1, and z is not equal to y); under certain reaction conditions such as heating temperature and heating time, the exchange of Cd and Zn ions in the inner and outer nanocrystals (that is, the above two-layer compounds) occurs. ; Since the migration distance of cations is limited and the longer the migration distance is, the less chance of migration occurs, so it will be in the Cd y Zn 1-y S layer and Cd z Zn 1-z A graded alloy composition distribution of Cd content and Zn content...

Embodiment 3

[0118] Example 3: Preparation based on CdZnSe / CdZnSe quantum dots

[0119] First, the precursor of cationic Cd, the precursor of cationic Zn and the precursor of anionic Se are injected into the reaction system to form Cd first y Zn 1-y Se layer (where 0≤y≤1); Continue to inject the precursor of cationic Cd, the precursor of cationic Zn and the precursor of anionic Se into the reaction system, and the above-mentioned Cd y Zn 1-y Cd is formed on the surface of the Se layer z Zn 1-z Se layer (where 0≤z≤1, and z is not equal to y); under certain reaction conditions such as heating temperature and heating time, the exchange of Cd and Zn ions in the inner and outer nanocrystals occurs; due to the limited migration distance of cations And the farther the migration distance is, the smaller the probability of migration occurs, so it will be in the Cd y Zn 1-y Se layer and Cd z Zn 1-z A graded alloy composition distribution of Cd content and Zn content is formed near the interf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com