Lithium ion battery manganese-enriched anode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced discharge capacity of materials and fast decay of material capacity, so as to suppress unfavorable phase transitions, improve rate performance, and enhance structural stability The effect of stability and interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

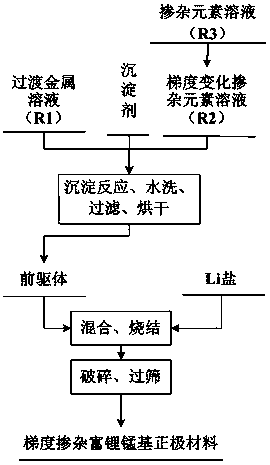

Method used

Image

Examples

Embodiment 1

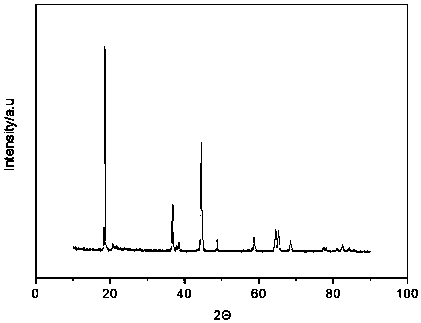

[0047] A lithium-rich manganese-based positive electrode material with Ti gradient doping. The initial metal ion ratio in the material is Mn:Ni:Co =0.6750:0.1625:0.1625, and the content of the doping element Ti increases from the particle core to the particle surface, changing The rule is 0~0.02. The average composition of the resulting material is Li[Li 0.2 mn 0.53 Ni 0.13 co 0.13 Ti 0.01 ]O 2 , with an average particle size of about 12.0 μm and a tap density of about 2.6 g / cm 3 .

[0048] The specific preparation method is as follows:

[0049] Prepare a 1.5 mol / L mixed solution with a molar ratio of manganese carbonate, nickel carbonate and cobalt carbonate of 0.6750:0.1625:0.1625 and record it as solution (1) and put it into sub-tank R1. Prepare the solution containing titanyl sulfate stabilizer as solution (2) and put it into sub-tank R2, and prepare a 2mol / L solution of titanyl sulfate as solution (3) and put it into sub-tank R3. The solution of R3 sub-tank is ad...

Embodiment 2

[0052] A lithium-rich manganese-based positive electrode material with Ti gradient doping. The initial metal ion ratio in the material is Mn:Ni:Co =0.6750:0.1625:0.1625, and the content of the doping element Ti increases from the particle core to the particle surface, changing The rule is 0~0.02. The average composition of the resulting material is Li[Li 0.2 mn 0.53 Ni 0.13 co 0.13 Ti 0.01 ]O 2 , with an average particle size of about 6.0 μm and a tap density of about 2.0 g / cm 3 .

[0053] The specific preparation method is as follows:

[0054] Prepare a 1.5 mol / L mixed solution with a molar ratio of manganese carbonate, nickel carbonate and cobalt carbonate of 0.6750:0.1625:0.1625 and record it as solution (1) and put it into sub-tank R1. Prepare the solution containing titanyl sulfate stabilizer as solution (2) and put it into sub-tank R2, and prepare a 2mol / L solution of titanyl sulfate as solution (3) and put it into sub-tank R3. Add the solution of the sub-tank o...

Embodiment 3

[0057] A lithium-rich manganese-based positive electrode material with Ti gradient doping. The initial metal ion ratio in the material is Mn:Ni:Co =0.70:0.15:0.15, and the content of the doping element Ti increases from the particle core to the particle surface, changing The rule is 0~0.02. The average composition of the resulting material is Li[Li 0.2 mn 0.55 Ni 0.12 co 0.12 Ti 0.01 ]O 2 , the average particle size is about 13.0 μm, and the tap density is about 2.5g / cm 3 .

[0058] The specific preparation method is as follows:

[0059] Prepare a 1.5 mol / L mixed solution with a molar ratio of manganese carbonate, nickel carbonate and cobalt carbonate of 0.70:0.15:0.15 and record it as solution (1) and put it into sub-tank R1. Prepare the solution containing titanyl sulfate stabilizer as solution (2) and put it into sub-tank R2, and prepare a 2mol / L solution of titanyl sulfate as solution (3) and put it into sub-tank R3. The solution of R3 sub-tank is added to R2 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com