Pool striding walking type leaf cutting machine based on belt type cutting

A walking-type, leaf-cutting machine technology, applied in cutting tools, cutting equipment, agricultural machinery and implements, etc., to achieve the effect of avoiding repetitive labor, high efficiency in collecting residual leaves, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

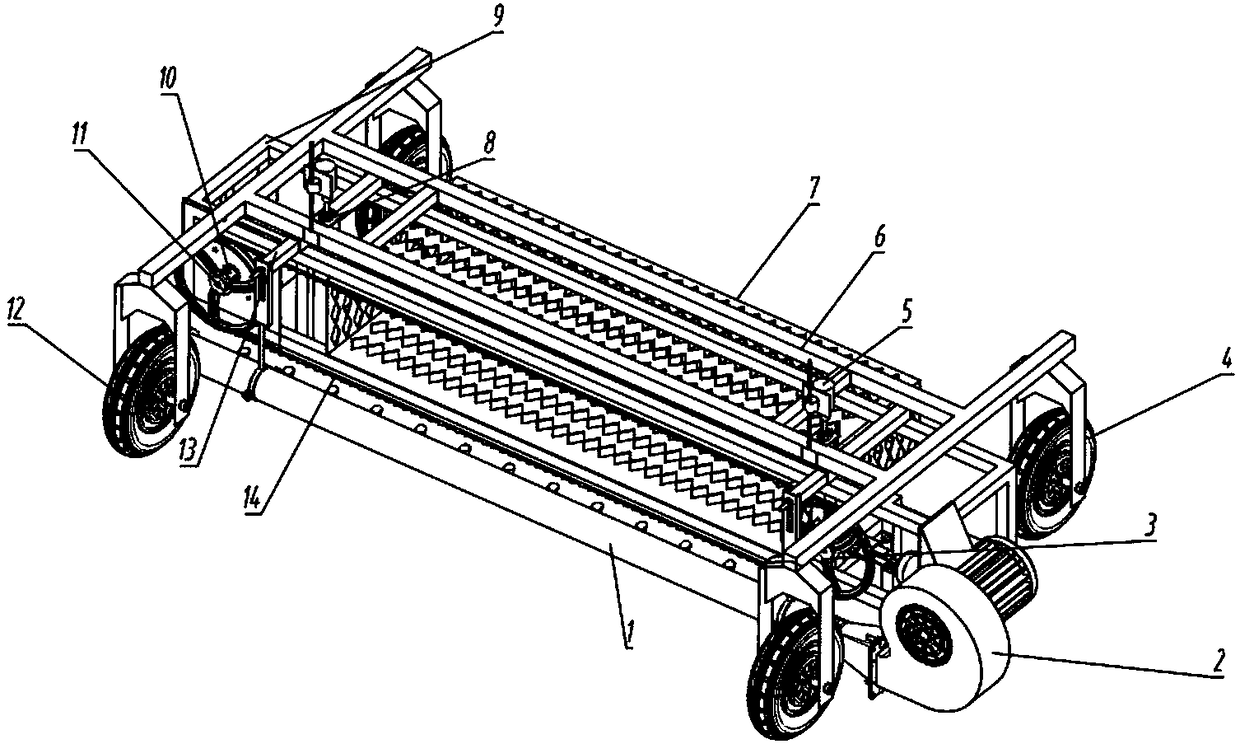

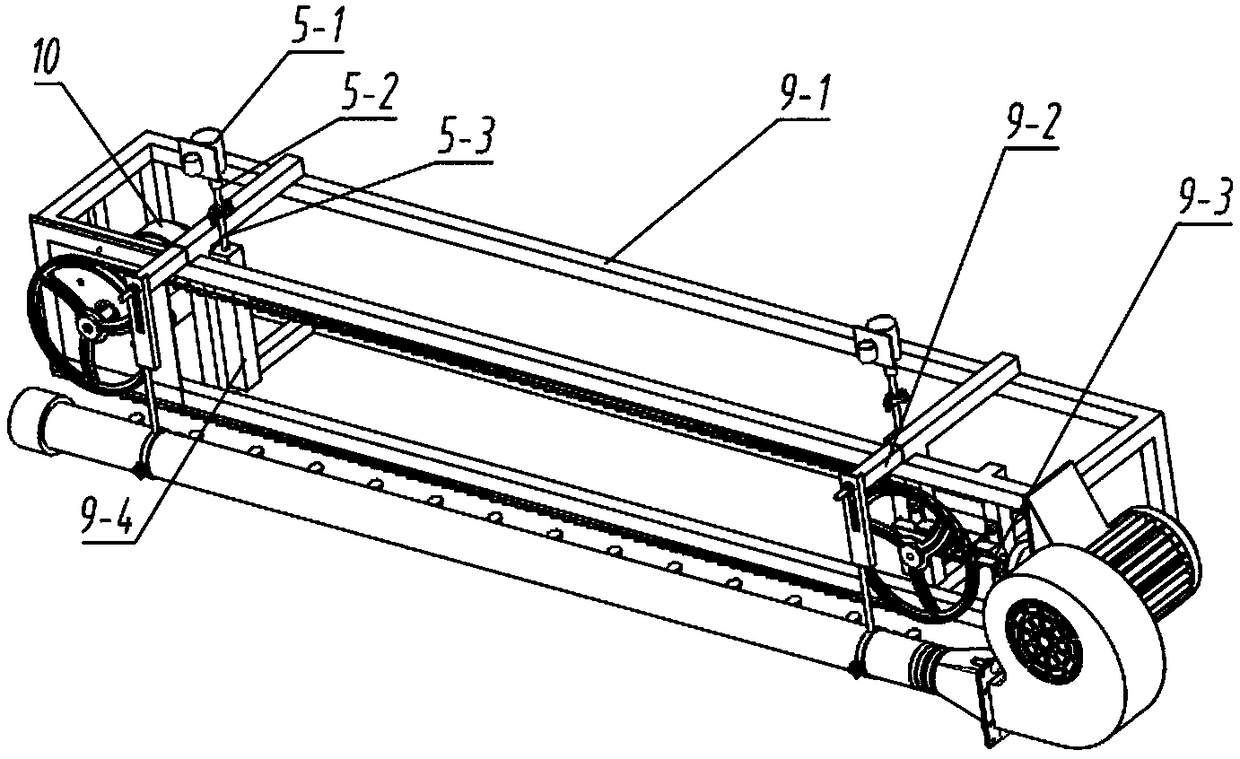

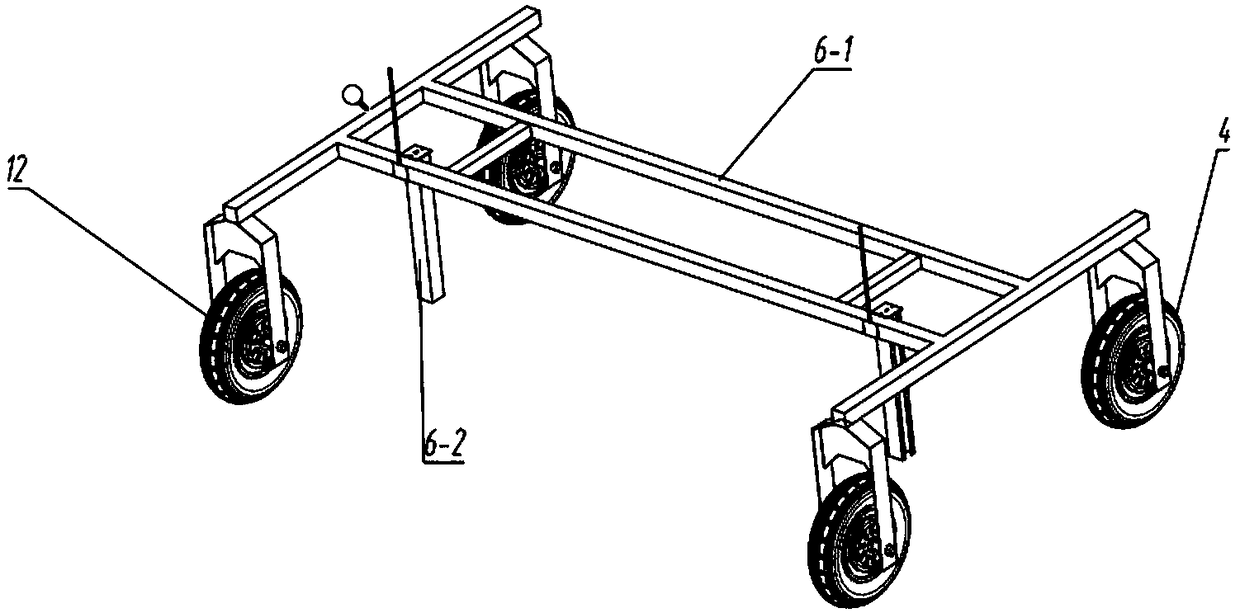

[0028] see figure 1 , 2 , the present invention proposes a cross-basin walking leaf shearer based on a belt cutting and hub motor, including a traveling mechanism (6), a leaf clipping collection device (9) and a lifting device (5). The leaf clipping collecting device (9) comprises the clipping leaf collecting device frame (9-1), and the clipping leaf collecting device frame (9-1) can be a frame structure to facilitate manufacture, and the clipping leaf collecting device frame (9 -1) The frame structure can be made of multi-section stainless steel pipes by welding to provide good structural strength, or the frame of the blade collecting device frame (9-1) is made of aluminum alloy profiles by welding, so that the blades can be collected The overall weight of the device frame (9-1) is reduced. One end of the frame of the shearing leaf collecting device near the blade is provided with a driving wheel (11) and a driven wheel (3), and the center of the driving wheel (11) is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com