Semi-automatic inclined ladder pairing assembling system

An assembly system and inclined ladder group technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor precision, increased manufacturing difficulty, and uneven step spacing of inclined ladders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

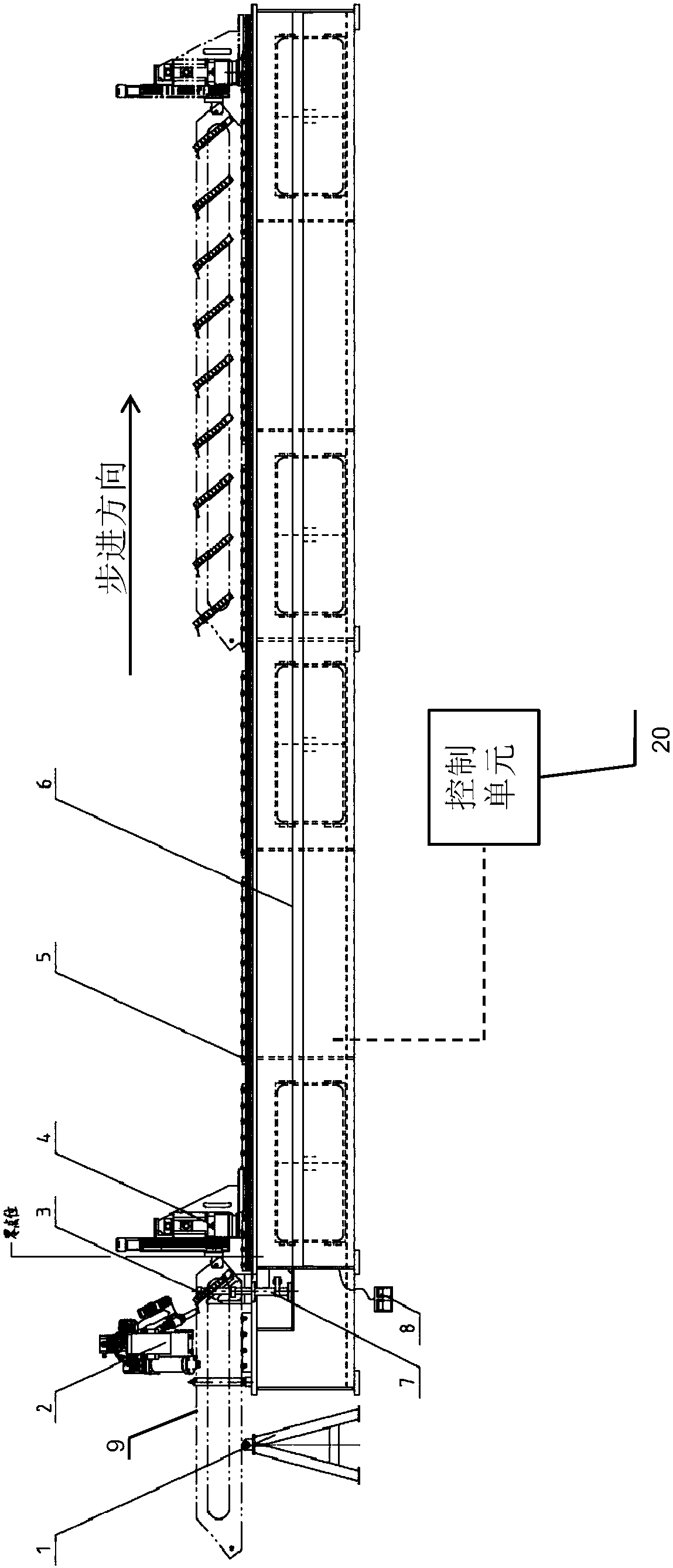

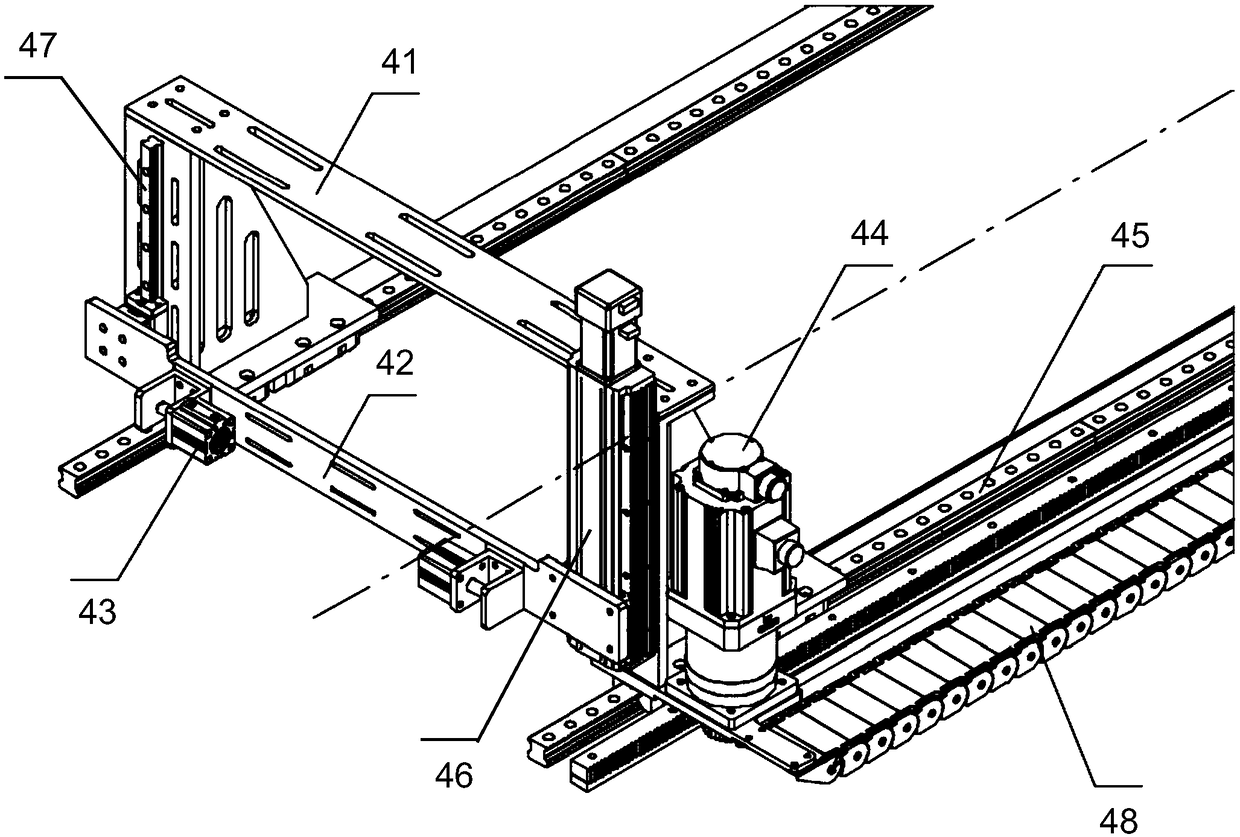

[0032] Please combine Figure 1 to Figure 8 As shown, a semi-automatic inclined ladder assembly system provided by the present invention includes: a workbench 6, a feed device 4 arranged on the workbench 6, an adjustable angle plate 3, a stepping fixture 7 and a special welding machine 2.

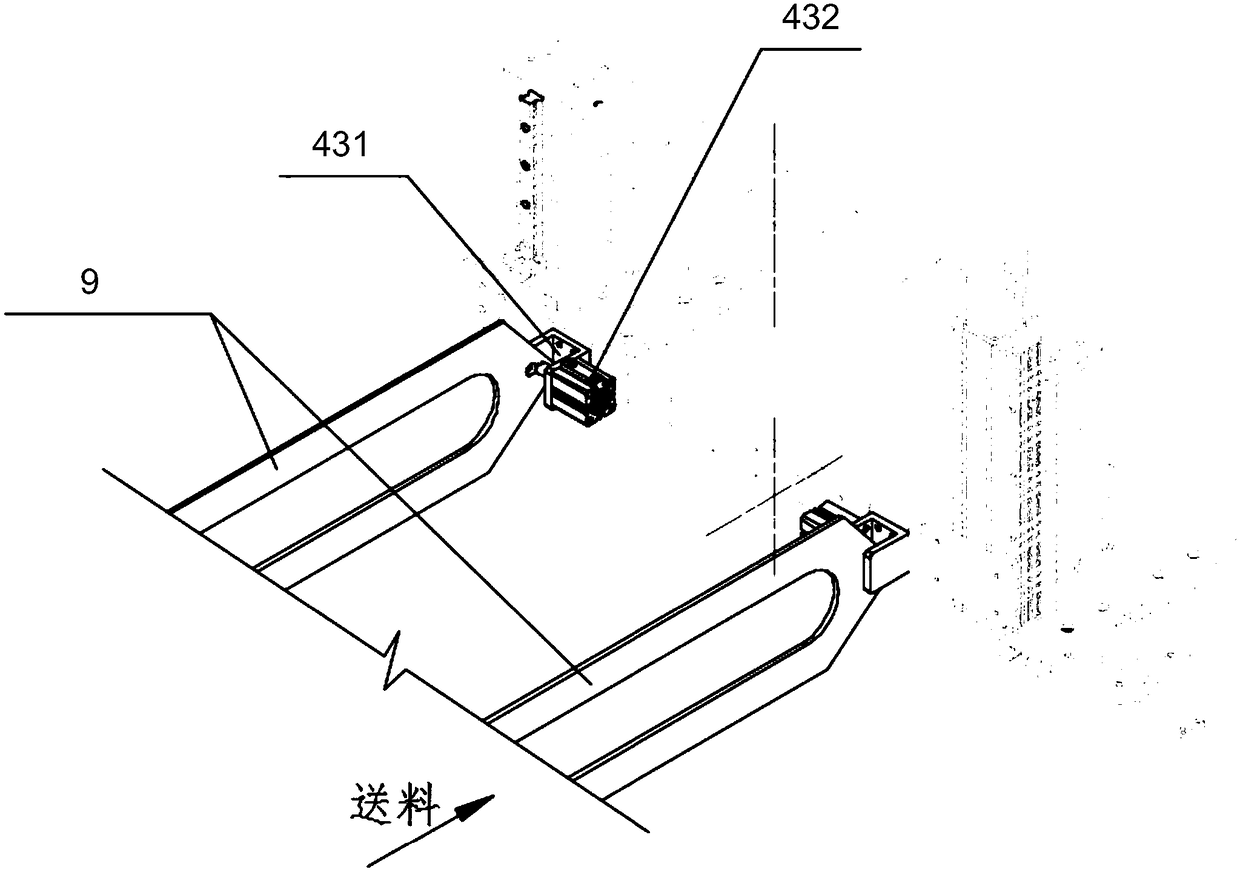

[0033] Preferably, the workbench 6 is made of Q345 steel plate, and after aging treatment, it has high rigidity, good flexibility resistance and excellent precision stability. As a carrier for integrating other components, it can Both sides of the upper surface of the roller are respectively provided with idler groups 5, and the surface treatment of idler group 5 is more wear-resistant, and the combined idler is used for easy replacement. When the ladder beam 9 steps along with the feeding device 4 , the ladder beam 9 moves on the idler r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com