Non-irritating and non-corrosive cleaning agent and preparation method thereof

A cleaning agent and non-corrosion technology, applied in chemical instruments and methods, detergent compositions, surface active detergent compositions, etc., can solve the adverse effects of people and the environment, poor degreasing and decontamination capabilities, and strong corrosiveness and other problems, to achieve the effect of low cost, strong degreasing and decontamination ability, and high production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A preparation method of a non-irritating and non-corrosive cleaning agent, comprising:

[0060] Steps for preparing materials: Weighing the sapinberry extract, alkyl glucoside, oleoyl sarcosinate, polyoxyethylene sorbitan monolaurate, dioctyl sulfosuccinate sodium and coconut oil fatty acid di ethanolamide;

[0061] Reaction steps: the weighed Sapindus chinensis extract, alkyl glucoside, sodium oleoyl sarcosinate, polyoxyethylene sorbitan monolaurate, dioctyl sulfosuccinate sodium and coconut oil fatty acid diethanol Put the amides into the reaction pot in order, and stir while adding the raw materials; after all the raw materials are put into the reaction pot, start to heat up while stirring, heat up to the preset temperature, keep warm, stir until completely dissolved after heat preservation, and get a semi-finished product;

[0062] Discharge step: After the semi-finished product cools down, discharge.

[0063] As a further embodiment, in the reaction step, after a...

Embodiment 1-5

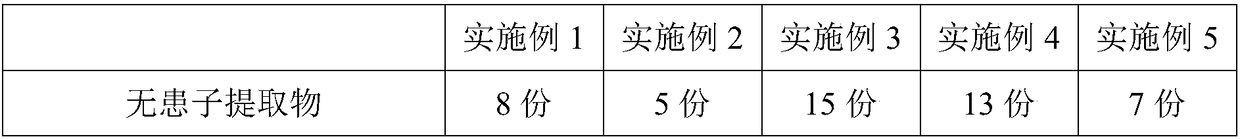

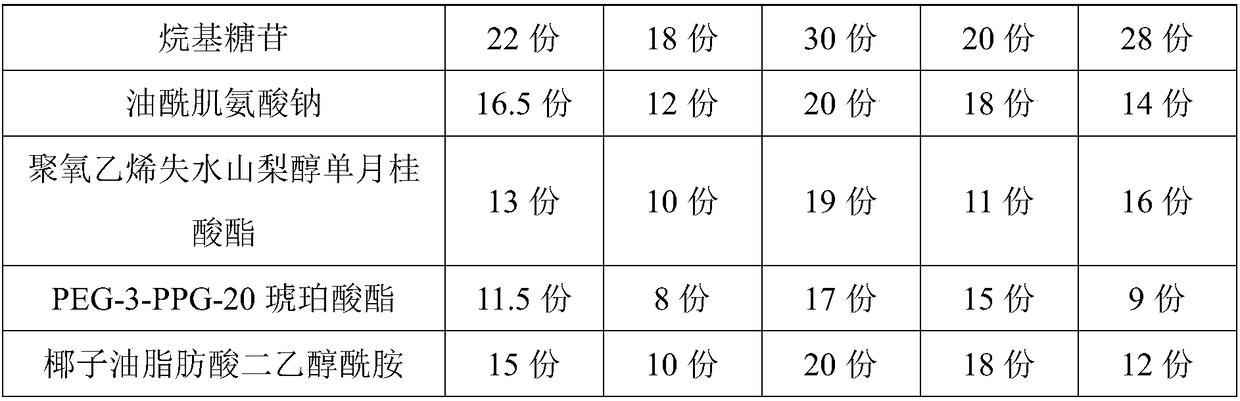

[0068] A non-irritating and non-corrosive cleanser comprising the following components: Sapinberry extract, Alkyl glycosides, Sodium oleoyl sarcosinate, Polyoxyethylene sorbitan monolaurate, Dioctyl sulfosuccinate Sodium and coconut fatty acid diethanolamide. The specific formula is shown in Table 1 below.

[0069] The non-irritating and non-corrosive cleanser formula table of table 1 embodiment 1-5

[0070]

[0071]

[0072] The non-irritating and non-corrosive cleaning agent of embodiment 1-5 is prepared according to the following method:

[0073] Reaction steps: Weigh Sapindus chinensis extract, alkyl glucoside, sodium oleoyl sarcosinate, polyoxyethylene sorbitan monolaurate, dioctyl sulfosuccinate sodium and coconut oil fatty acid di For ethanolamide, put the above materials into the reaction pot in order, and stir while adding the raw materials; after all the raw materials are put into the reaction pot, set the stirring speed to 300r / min, start to heat up while st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com