Heat treatment method of amorphous alloy

A heat treatment method and technology for amorphous alloys, applied in the field of preparation of amorphous alloys, can solve the problems of material embrittlement, complicated work, material failure, etc., and achieve the effects of good toughness, excellent soft magnetic properties, and easy selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of Amorphous Alloy Fe by Heat Treatment 77 Si 2.7 B 14.9 P 4 C 1.4 , including the following steps.

[0027] (1) Select Fe 77 Si 2.7 B 14.9 P 4 C 1.4 Alloy, the strip is prepared by rapid quenching and solidification at a high copper roll speed of 40m / s;

[0028] The microstructure of the ribbon was detected by XRD, and the ribbon was completely amorphous.

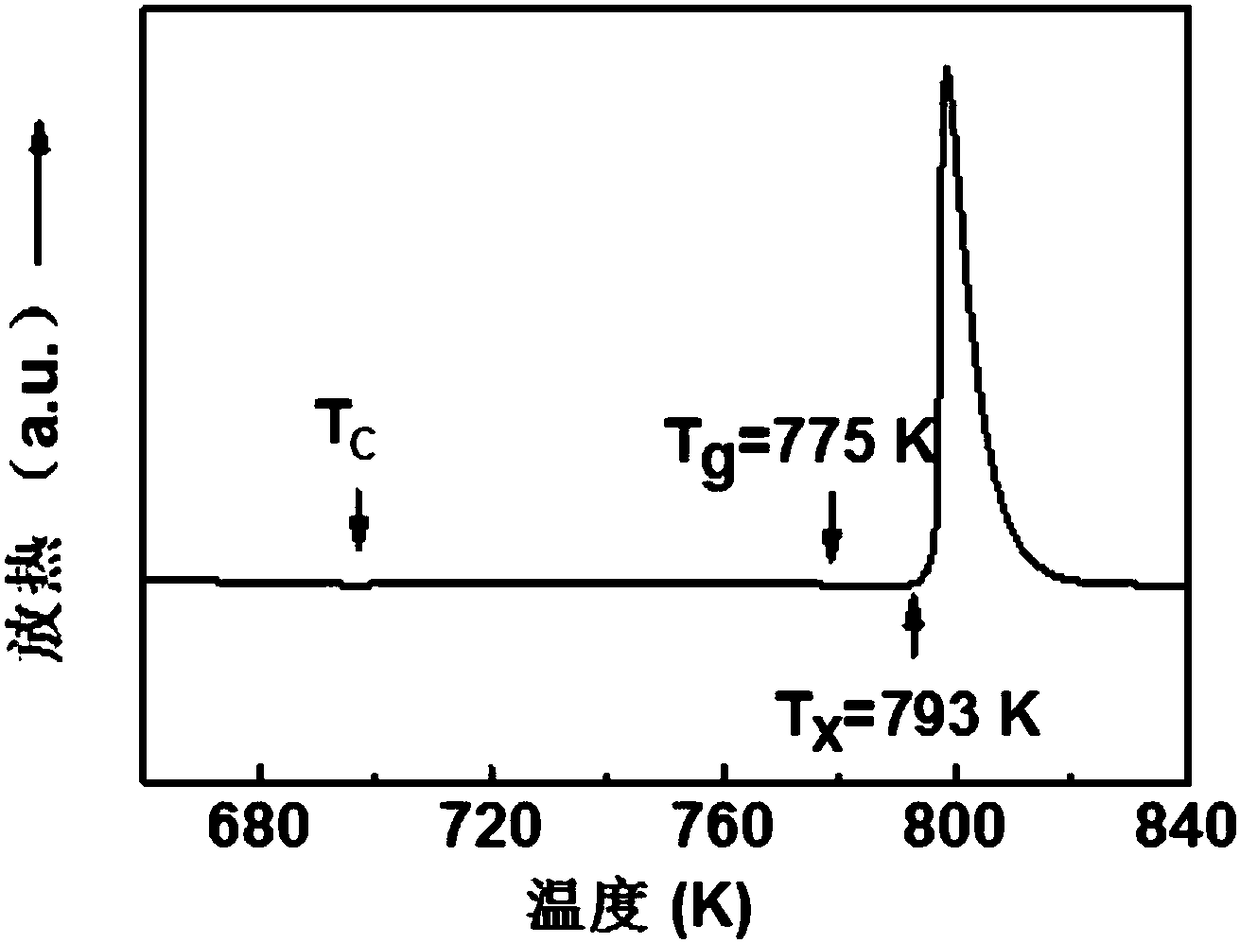

[0029] The glass transition temperature and crystallization temperature of the strip were detected by DSC at a heating rate of 40°C / min. Such as figure 1 As shown, the crystallization initiation temperature Tx is 793K, and the glass transition temperature Tg is 775K.

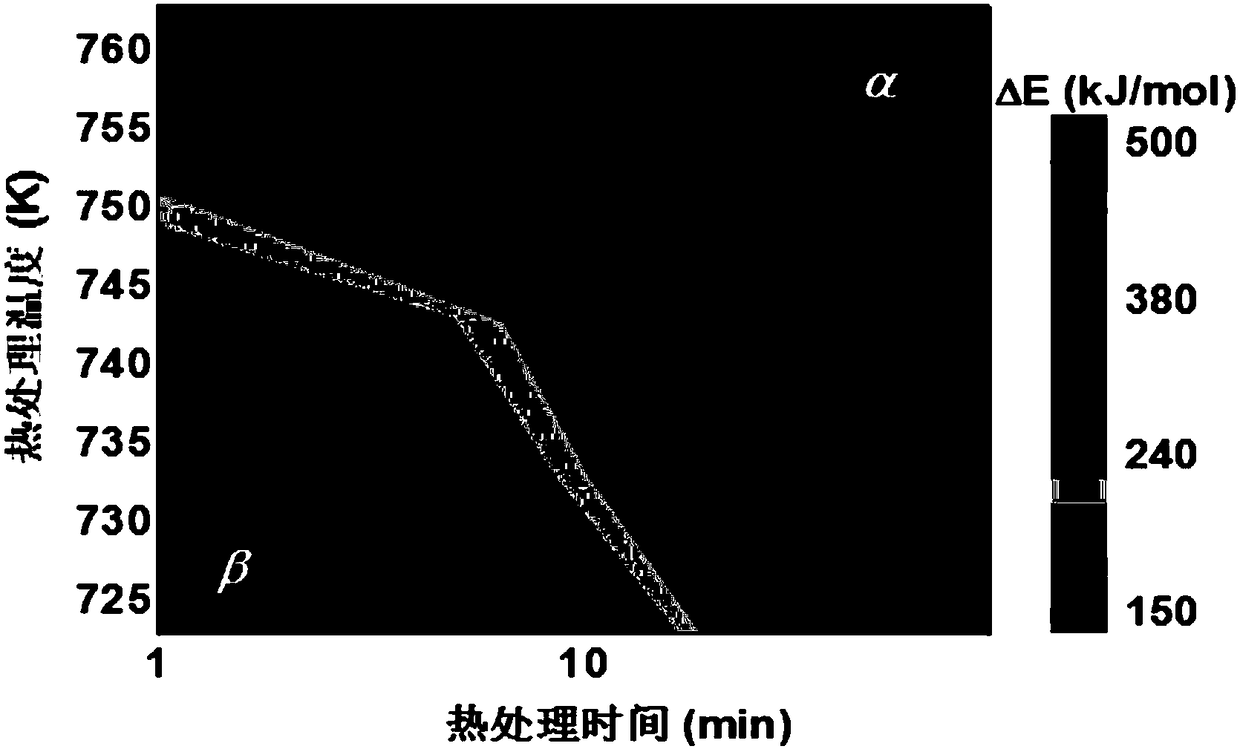

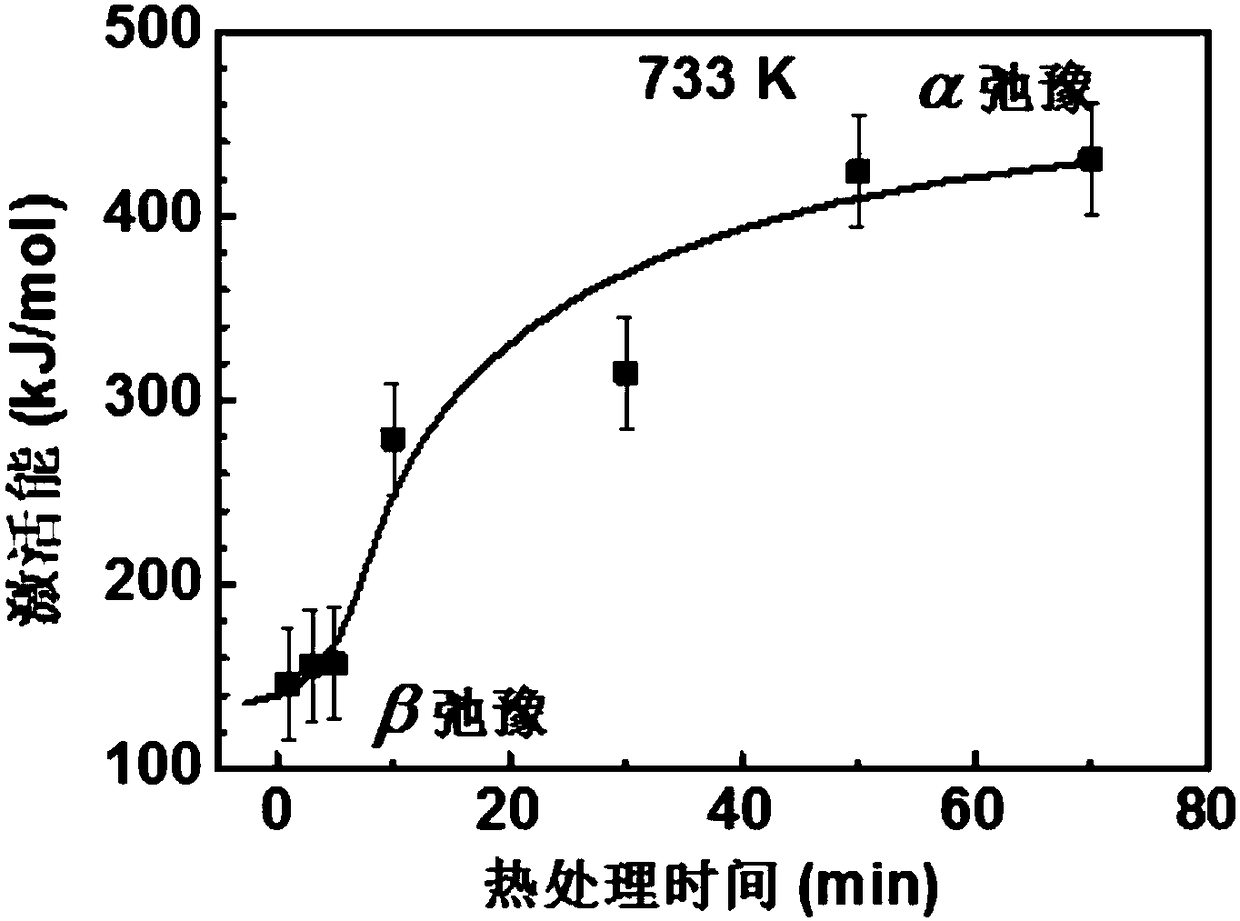

[0030] (2) Construct a two-dimensional coordinate system with time and temperature as the horizontal and vertical coordinates, test the in-situ annealing DSC data of the amorphous strip at different times and temperatures, and calculate the relaxation requirements based on the relaxation peaks at different heating rates The ov...

Embodiment 2

[0052] Preparation of Amorphous Alloy Fe by Heat Treatment 77 Si 2.7 B 14.9 P 4 C 1.4 , including the following steps.

[0053] (1) is exactly the same as step (1) in embodiment 1;

[0054] (2) exactly the same as step (2) in embodiment 1;

[0055] (3) In the present embodiment, select 743K (below Tg 30K) as heat treatment temperature, it is advisable to carry out heat treatment 1-8 minute under this heat treatment temperature, select heat treatment 5 minutes in the present embodiment, be specifically:

[0056] Use a fast heating furnace to raise the temperature of the strip to 743K and then keep it warm. The heating speed is selected as 400K / min, and the holding time is 5 minutes, and then it is taken out and air-cooled.

[0057] Tested by the bending and tearing device, the heat-treated strip has excellent toughness, and the bending and tearing radius is less than 0.5mm, which can meet the post-processing in the industry.

[0058] The samples after heat treatment were...

Embodiment 3

[0066] Preparation of Amorphous Alloy Fe by Heat Treatment 76 Si 9 B 10 P 5 , including the following steps.

[0067] (1) Select Fe 76 Si 9 B 10 P 5 Alloy, the strip is prepared by rapid quenching and solidification at a high copper roll speed of 40m / s;

[0068] The microstructure of the ribbon was detected by XRD, and the ribbon was completely amorphous.

[0069] The glass transition temperature and crystallization temperature of the strip were detected by DSC at a heating rate of 40°C / min. The crystallization initiation temperature Tx is 832K, and the glass transition temperature Tg is 780K.

[0070] (2) Construct a two-dimensional coordinate system with time and temperature as the horizontal and vertical coordinates, test the in-situ annealing DSC data of the amorphous strip at different times and temperatures, and calculate the relaxation requirements based on the relaxation peaks at different heating rates The overcome energy barrier, that is, the relaxation act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com