Optimization method of cooling lubrication process parameters in micro-lubrication cutting processing

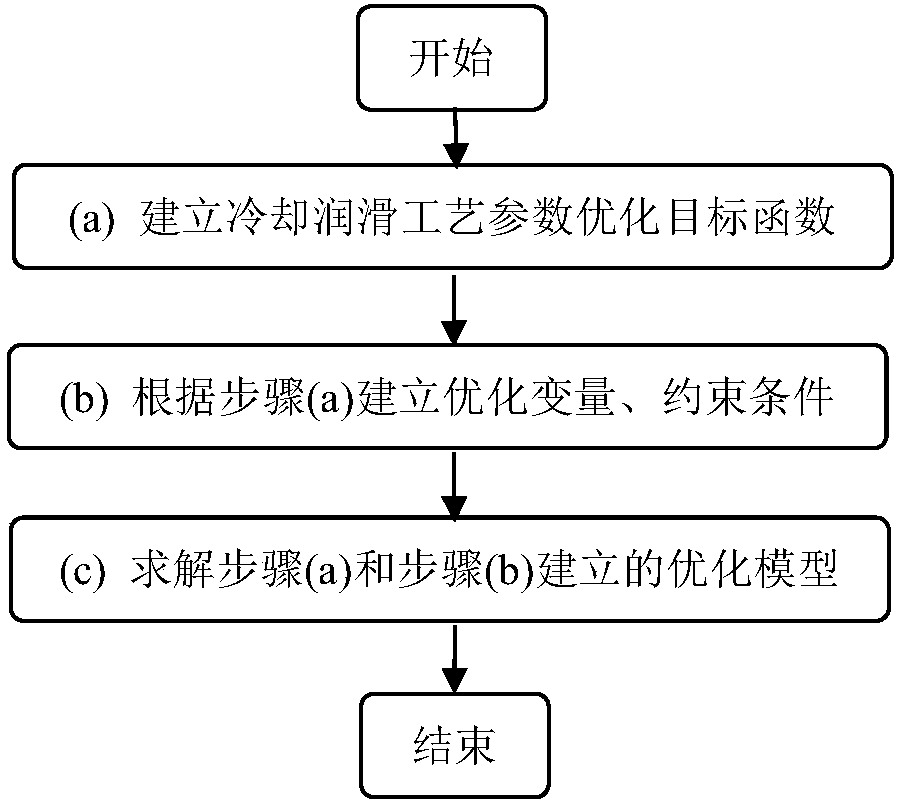

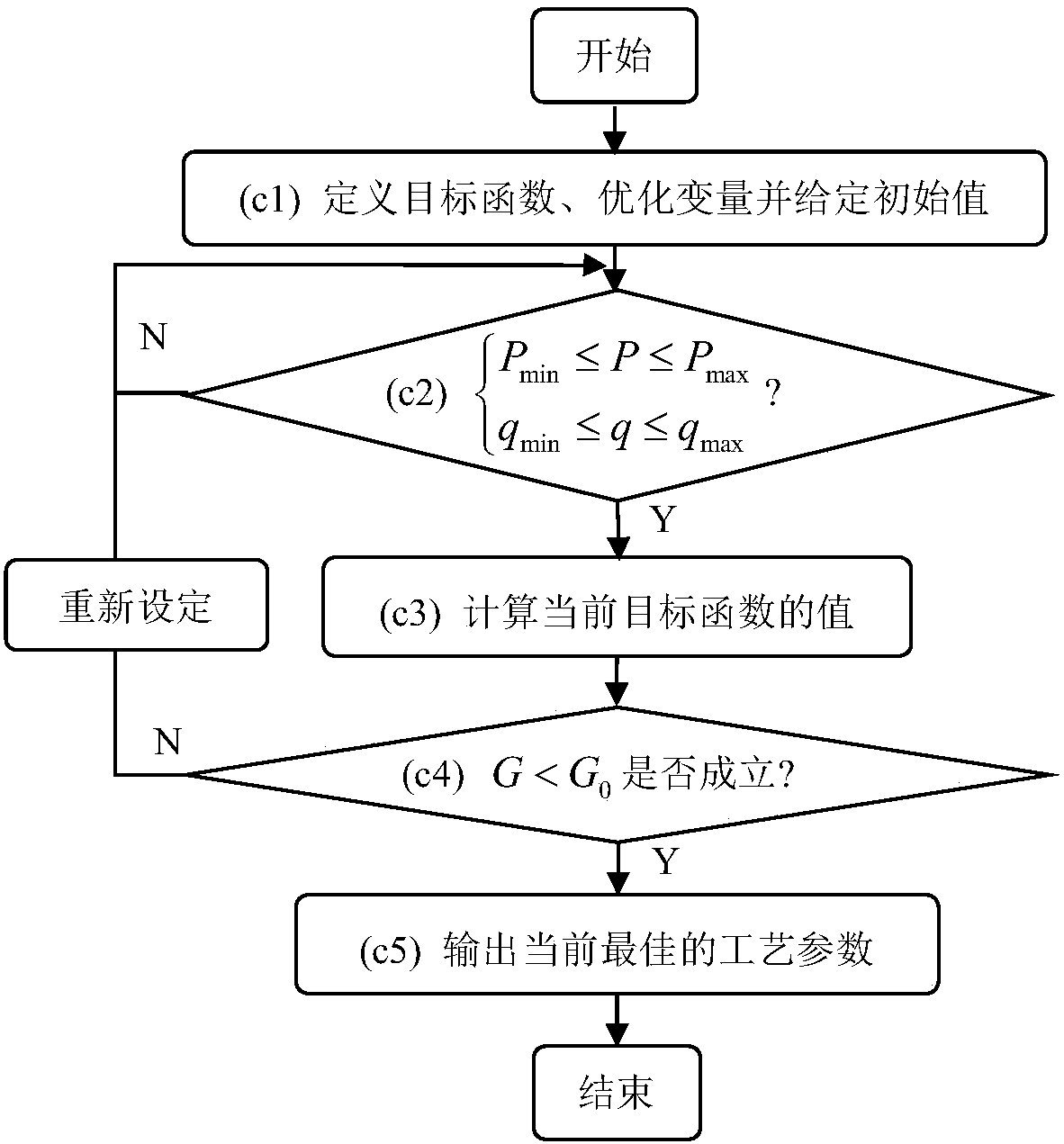

A technology of process parameter optimization and cooling and lubrication, which is applied in the directions of multi-objective optimization, design optimization/simulation, electrical digital data processing, etc., can solve the problem of lack of systematic experimental research on MQL cutting technology and the lack of cooling and lubrication effect of MQL cutting Evaluation and other issues to achieve the effect of improving processing quality, improving cooling and lubrication effect, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

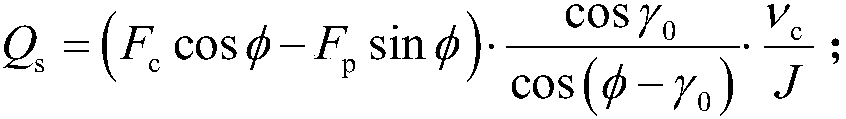

Method used

Image

Examples

example

[0106] In order to verify the present invention, the cooling and lubricating process parameters are optimized and calculated by experiments when the minimum quantity lubrication cutting process is carried out, the experimental processing technology is turning, the machine tool is CA6140, and the sample material is Ti6A14V (TC4), diameter d=150mm, total length l=150mm, The specific experimental parameters and the selection of micro-lubrication parameters are shown in Table 1. The tool is a TiCN-coated WC-based carbide turning tool with a coating thickness of 3-4 μm. The geometric parameters are shown in Table 2. The tool has an internal passage. The liquid method, the gas medium is compressed air, and the lubricating liquid used is MIRCOL-UBE1000-20 type vegetable oil, an environmentally friendly lubricating oil from Anmolin Company. The nozzle is located on the rake face of the tool, and has an included angle of 45° with the direction of the machine tool spindle.

[0107] Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com