Boiler inner wall intersecting line weld joint identifying method

An identification method and intersecting line technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of large welding seam deviation, large calculation scale, and large welding error of intersecting lines, and achieve strong applicability. , the effect of less inclination adjustment steps and simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

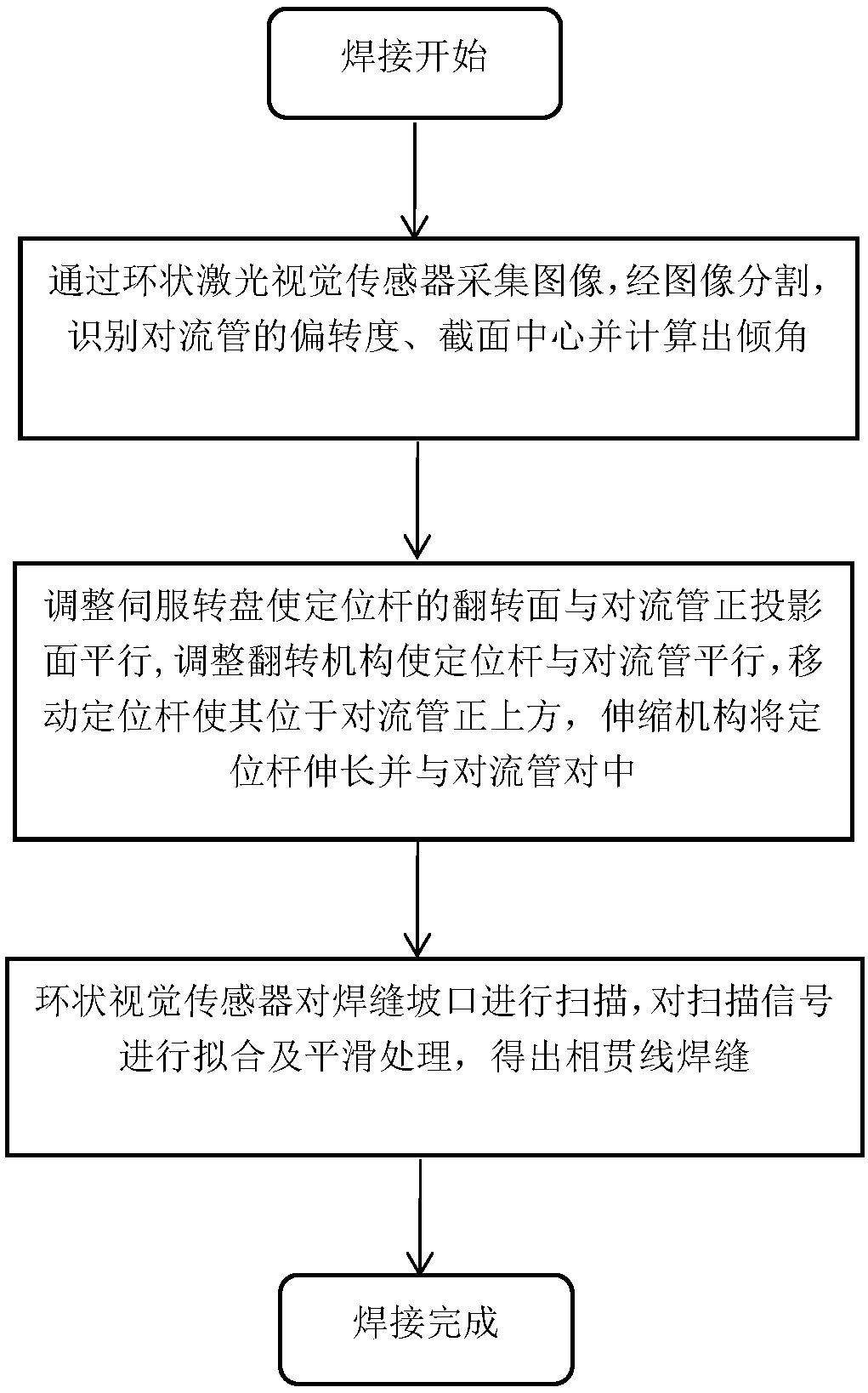

[0020] figure 1 It is a flow chart of identifying intersecting line welds on the inner wall of a boiler provided by a specific embodiment of the present invention.

[0021] like figure 1 As shown, the method includes the following steps:

[0022] 1) Start welding, collect images through the ring-shaped laser vision sensor, and through image segmentation, identify the deflection degree and section center of the convection tube and calculate the inclination angle;

[0023] 2) Adjust the servo turntable so that the flip surface of the positioning rod is parallel to the orthographic projection surface of the convection tube, adjust the flipping mechanism so that the positioning rod is parallel to the convection tube, move the positioning rod so that it is directly above the convection tube, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com