Categorical regression mode based operating condition self-adaptive equipment health degree assessment method

A healthy and self-adaptive technology, applied in data processing applications, instruments, predictions, etc., to achieve the effect of improving accuracy and adaptability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

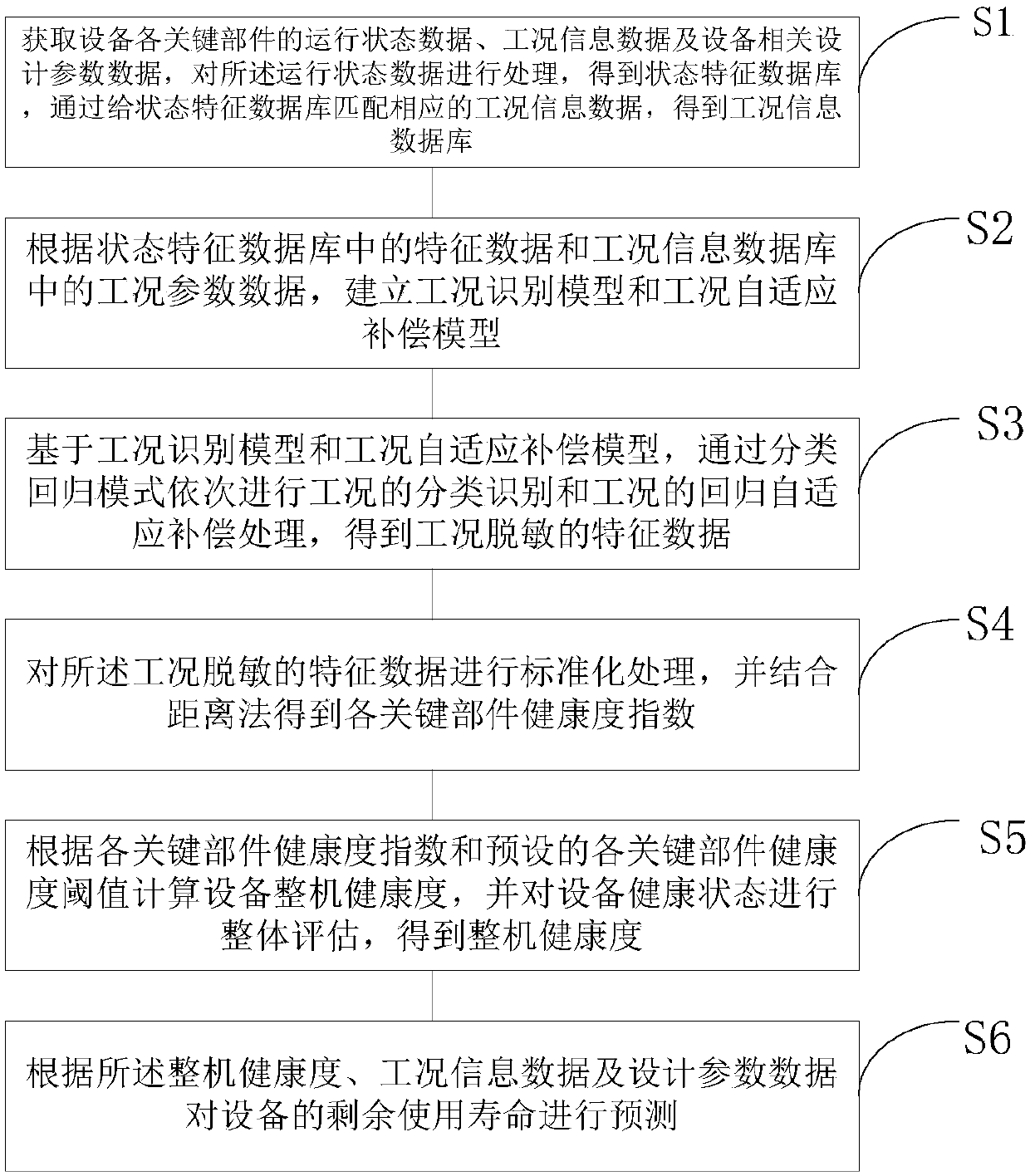

[0059] A method for evaluating the health of equipment based on classification and regression models for working condition adaptation, such as figure 1 shown, including the following steps:

[0060] S1. Obtain the operating status data, working condition information data and equipment-related design parameter data of each key component of the equipment, process the operating status data to obtain a status feature database, and match the corresponding working condition information data to the status feature database, Get working condition information database;

[0061] S2. Establish a working condition identification model and a working condition adaptive compensation model according to the characteristic data in the state characteristic database and the working condition parameter data in the working condition information database;

[0062] S3. Based on the working condition identification model and the working condition self-adaptive compensation model, through the classific...

specific Embodiment

[0107] Utilize the method of the present invention, the technical effect of the present invention is described in conjunction with specific equipment.

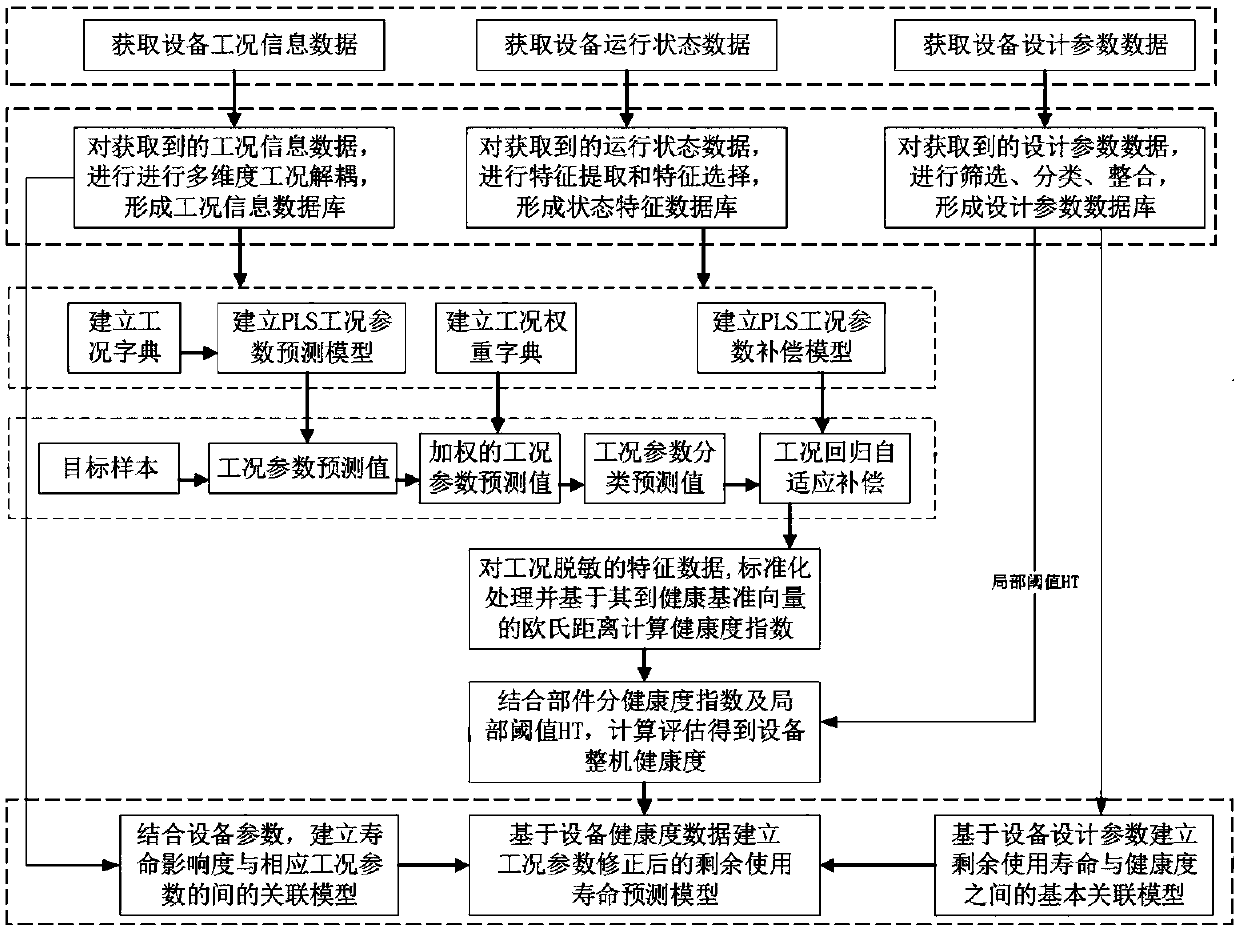

[0108] refer to figure 1 and figure 2 , the relevant design parameter data of the equipment collected include its design service life, rated speed, rated load, service life, theoretical decay law parameters, etc.

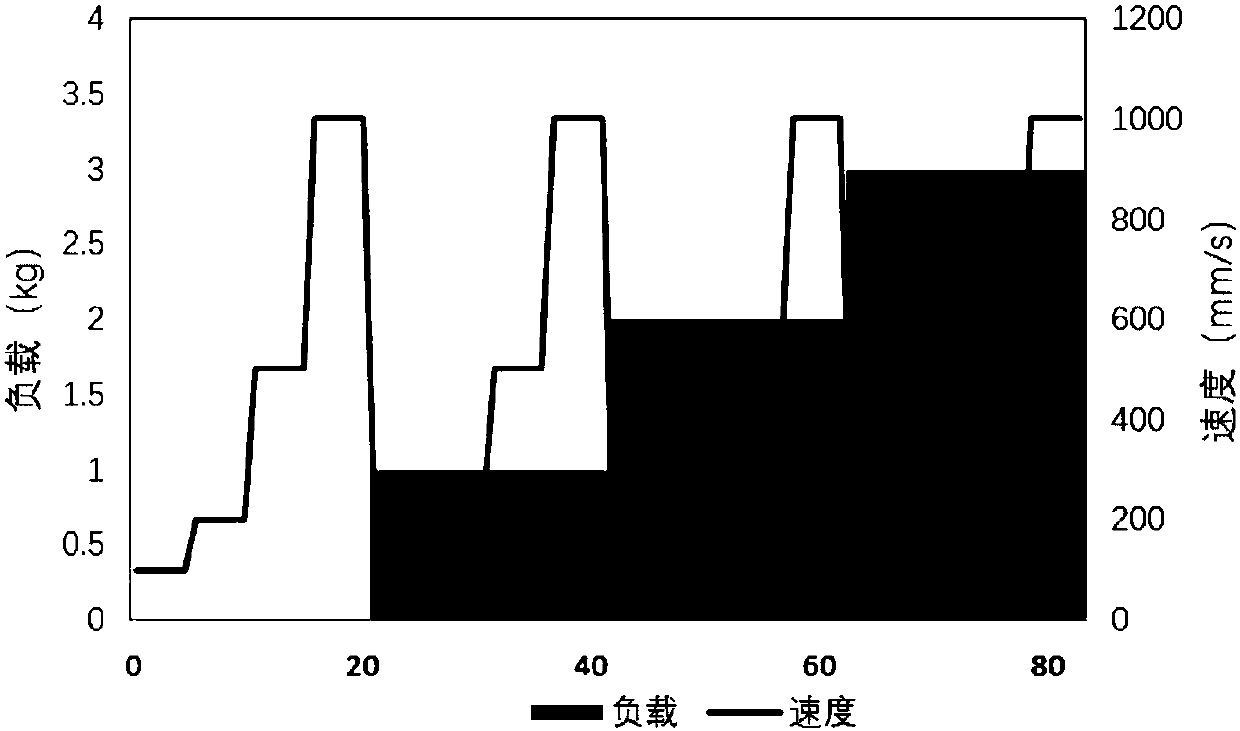

[0109] In order to verify the self-adaptive equipment health evaluation method based on the classification regression model proposed by the present invention, here, the specific equipment is a six-axis joint type industrial robot, and the collected data is: working condition information data, mainly including The real-time overall operating speed and load of industrial robots, the operating state data of each joint of industrial robots mainly include the torque and current data of each joint; the state feature database is extracted from the torque or current data of each joint through signal time domain features a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com