Cylindrical battery anti-vibration electrode cover plate

A technology for cylindrical batteries and electrode caps, which is applied to battery components, circuits, electrical components, etc., and can solve problems such as battery internal resistance, multiplier and other performance hazards, metal current collecting disc bending breaks, winding cores shaking back and forth, etc. , to reduce the risk of desoldering and breakage at the bend, ensure the consistency of reliability and function, and increase the effect of stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

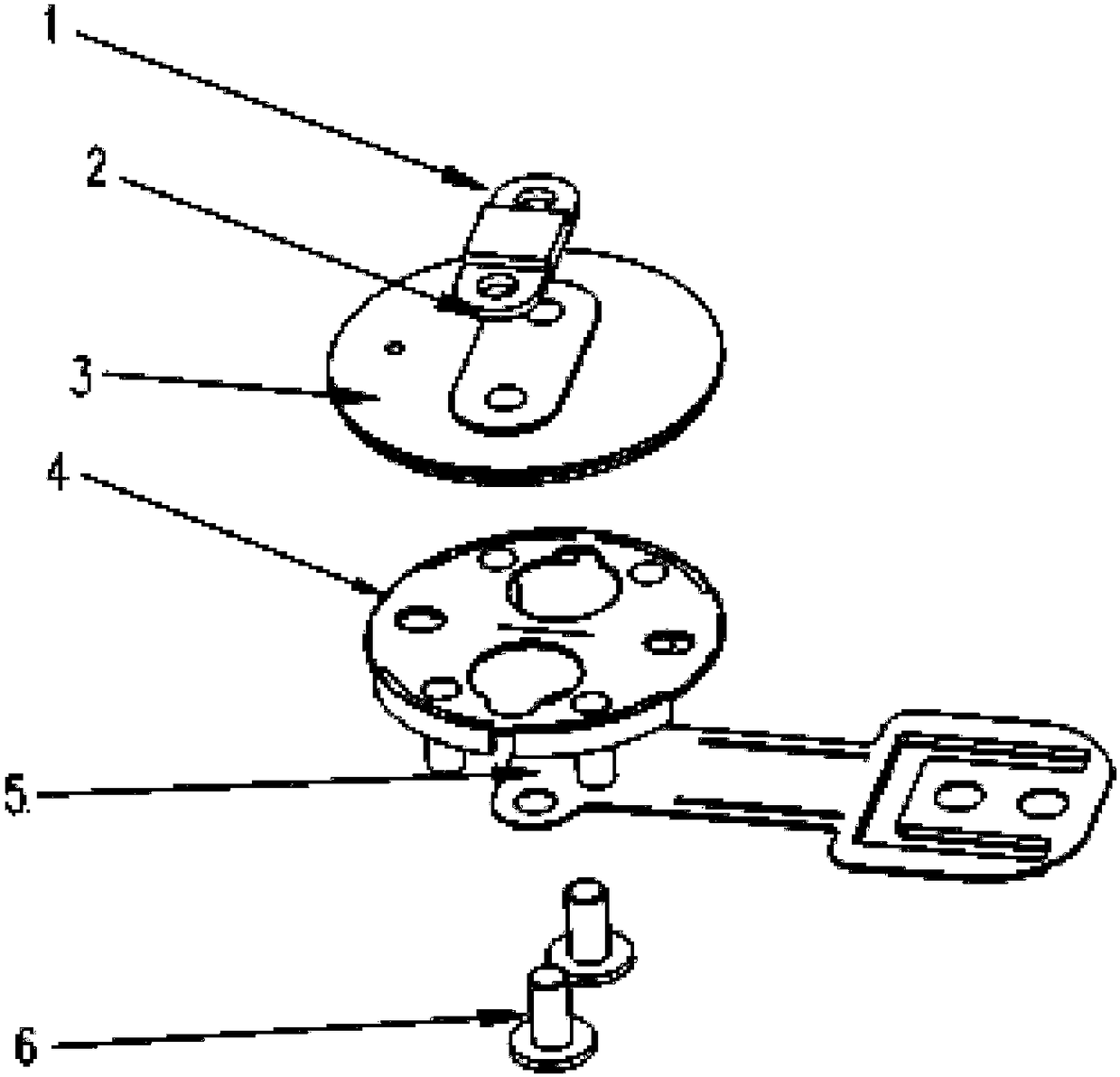

[0023] This embodiment is a cylindrical battery anti-vibration electrode cover plate:

[0024] It includes a conductive cover plate 3, a pole plate 1, a pole piece 5, and a connecting body 6 composed of aluminum rivets.

[0025] There are two through holes in the cover plate 3, and a connecting body 6 runs through the through holes vertically. An upper insulating layer 2 is clamped between the upper layer of the cover plate 3 and the pole plate 1, and the lower layer of the cover plate 1 is connected to the pole piece 5. riveted.

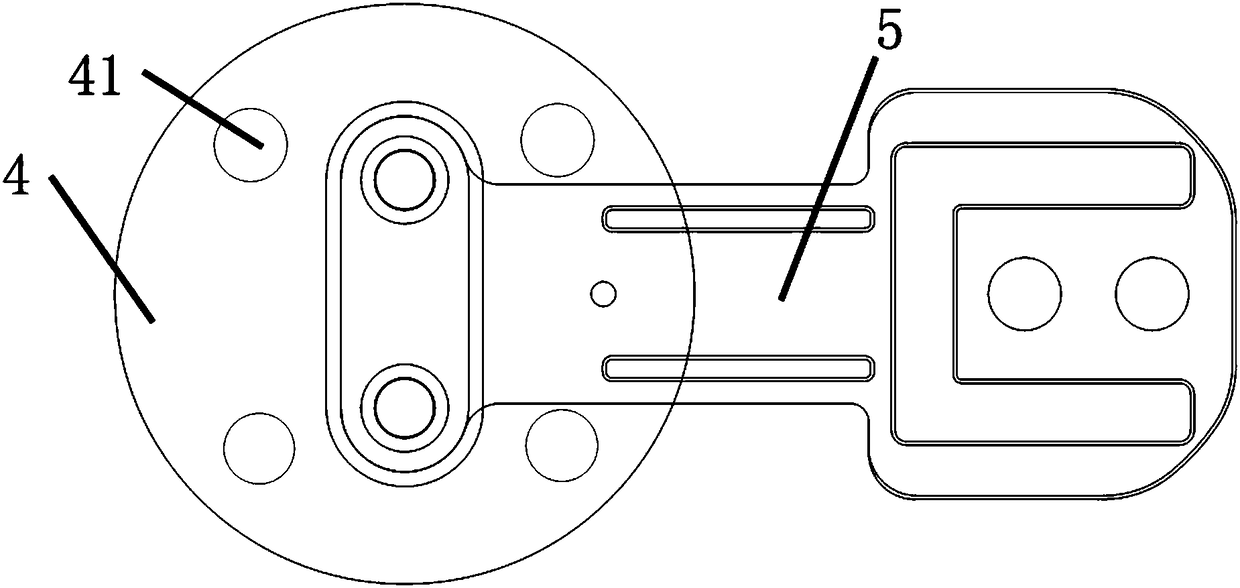

[0026] A stop frame 4 is arranged between the cover plate 3 and the pole piece 5 .

[0027] The connecting body and the pole plate 1 form an electrode assembly.

[0028] The U-shaped collector plate groove provided at one end of the pole piece 5 is used for the conductive contact of the inner winding tab welding of the cylindrical battery, and there are two molded reinforcing ribs at the bending place for the connection of the pole piece 5, It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com