ECM (electrochemical machining) motor and method for constant torque control based on accurate flux linkage look-up table method

A control method and constant torque technology, applied in the direction of single motor speed/torque control, connection with control/drive circuit, control system, etc., can solve the problems of reducing control accuracy, bus current fluctuation, increasing cost, etc. The effect of improving the protection level, small torque fluctuation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

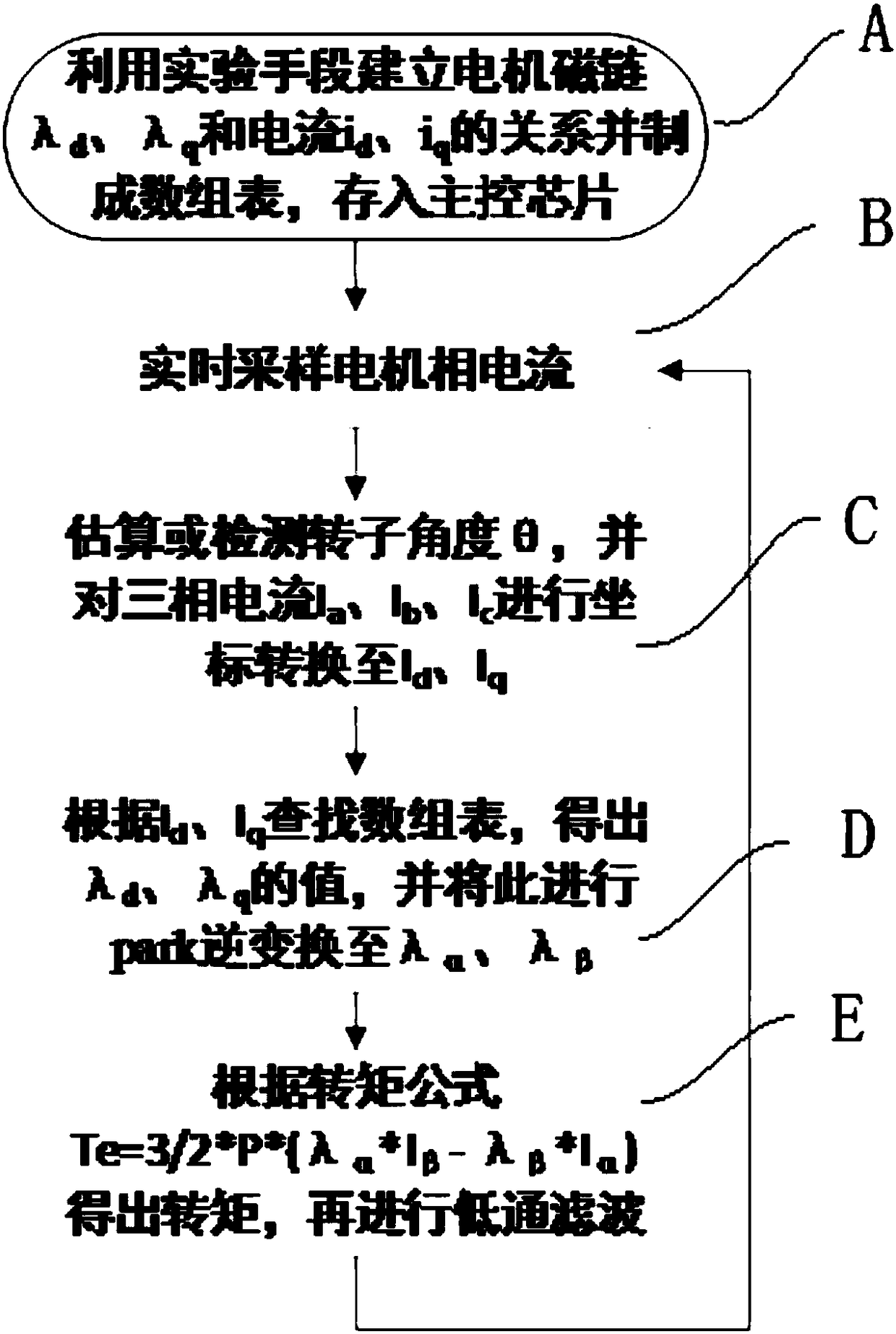

[0038] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

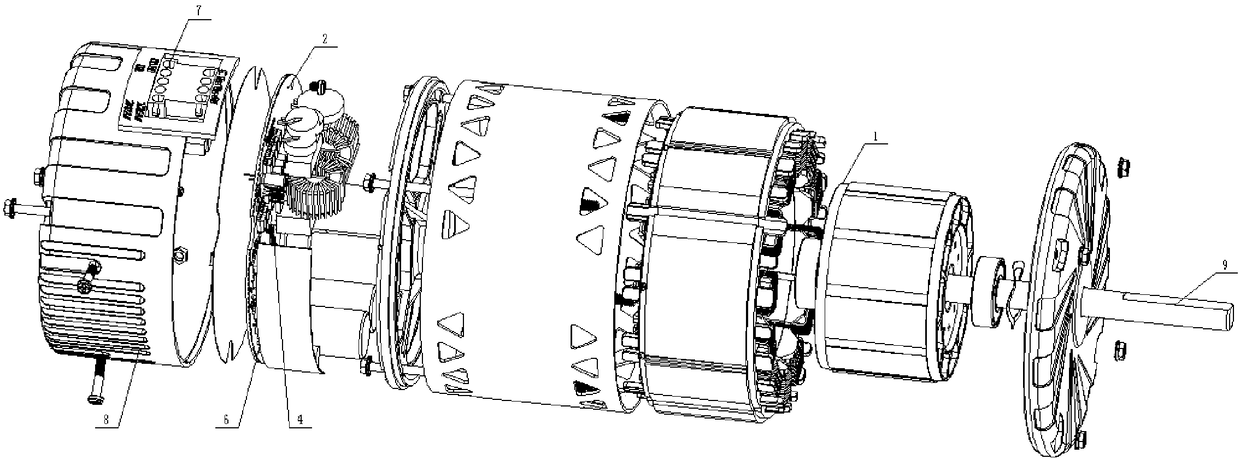

[0039] Such as Figure 1-2 As shown, an ECM motor with constant torque control based on the precise flux linkage look-up method includes a motor and a drive controller 2 for controlling the operation of the motor. The motor is a magnetic steel plug-in motor with reluctance torque, and the motor The casing and the drive controller 2 are set integrally or separately; the drive controller 2 is provided with a magnetic link λ for storing d with I d , I q The relationship between the d-axis flux motor parameter table and for storing λ q with I d , I q Relationship between the storage module 3 of the q-axis flux linkage motor parameter table.

[0040] In order to achieve smaller volume and better heat dissipation and protection effects, the rear end of the motor body 1 is provided with a rear cover 8, the output shaft 9 of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com