Ultra-low speed unit type splicing disc type magnetic levitation torque motor

A torque motor and unitized technology, which is applied in the field of magnetic levitation rotating devices, can solve the problems of occupying a considerable space and complex structure, and achieve the effects of low maintenance cost, improved control accuracy and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

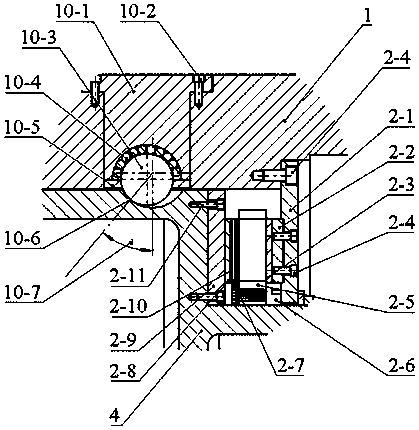

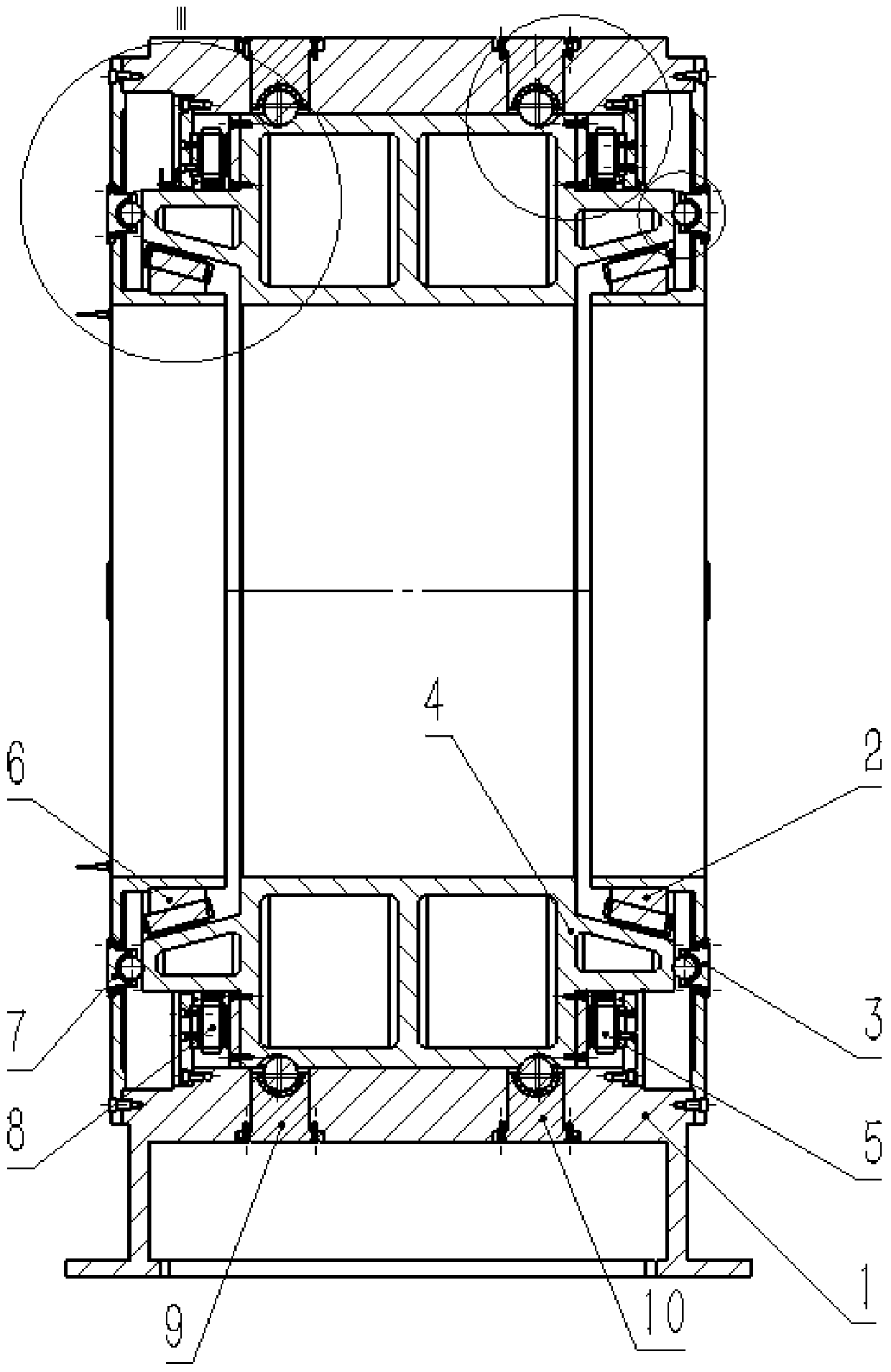

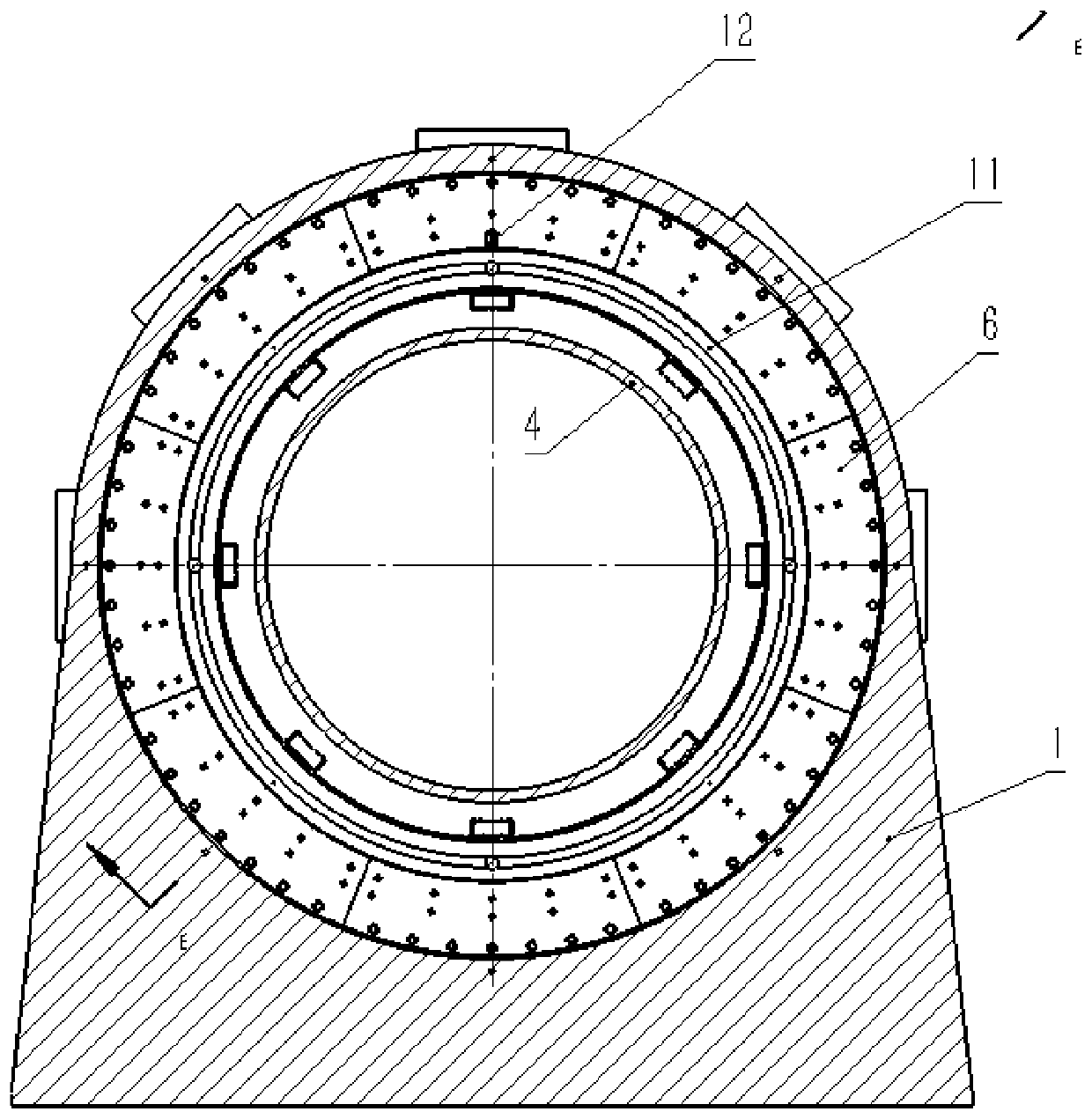

[0035] Components that correspond to each other or have the same function are identified with the same symbols in all figures.

[0036] like Figure 1-Figure 5 As shown, the unit type spliced disc type direct drive motor and its magnetic suspension rotating shaft of the present invention are mainly composed of base 1, unit type spliced disc type direct drive motor 5, 8, tapered active magnetic suspension bearing 2, 6, radial protection bearing 9, 10, the axial protection bearing 3, 7, the rotating shaft 5, the axial conical active magnetic suspension bearing sensor 11, the axial conical active magnetic suspension bearing sensor 12, and the angular displacement sensor 13. The load is installed on the rotating shaft 4 and initialized before work. The tapered active magnetic suspension bearings 2 and 6 are initialized, and the control current is initialized according to the positions calibrated by the axial and radial tapered active magnetic suspension bearing sensors 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com