Method for adhering water soluble polymer films

A water-soluble polymer, polymer technology, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0032] abbreviation :

[0033] BA n-butyl acrylate

[0034] EA ethyl acrylate

[0035] EHA 2-Ethylhexyl Acrylate

[0036] HEMA 2-Hydroxyethyl methacrylate

[0037] MAA Methacrylic acid

[0038] MMA methyl methacrylate

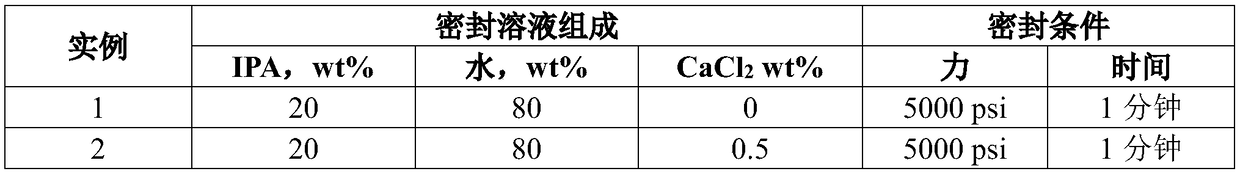

example 1-2

[0039] Example 1-2: Sealing solution containing ≥40wt% water, ≤60wt% isopropanol (IPA) and

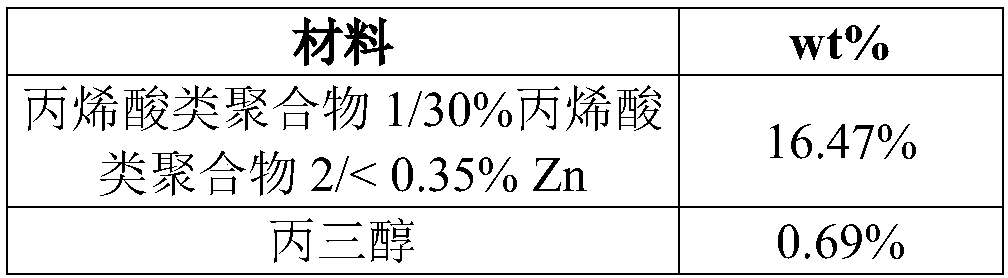

[0040] By mixing the desired amount of water, isopropanol, and metal salt (CaCl 2 ) were mixed together to prepare two sealing solutions having the compositions shown in Table 1. The solution was stirred on a magnetic stir plate for 10 minutes and sonicated for 30 minutes before use. About 100 μm water soluble films were prepared by knife coating formulations containing blends of acrylic polymers with specific glass transition temperatures and other additives (Table 2). The membranes exhibit various desirable properties, including stability in high ionic strength aqueous solutions, and the ability to readily dissolve when ionic strength is reduced. The sealing strength of each sealing solution was then characterized by measuring the prepared samples using the INSTRON tensile test according to the method specified in ASTM F88 (Technique A). Specifically, the sealing solution was a...

example 3-5

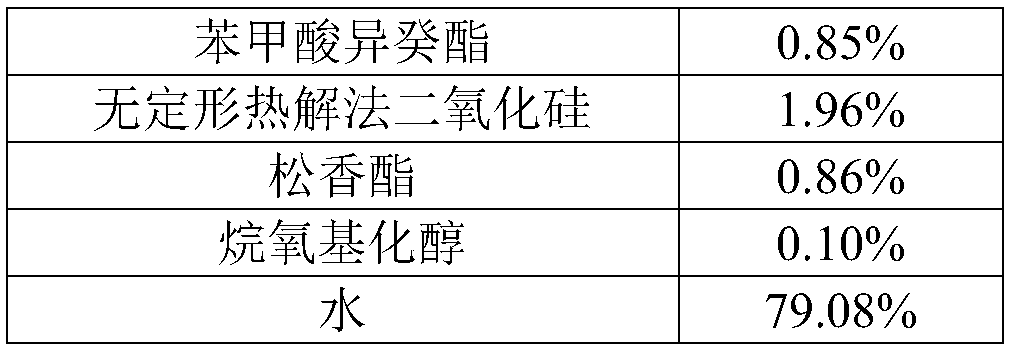

[0051] Examples 3-5: Sealing Solutions Containing Water and Propylene Glycol (PG)

[0052] Two sealing solutions with the compositions shown in Table 4 were prepared by mixing the solvents together in glass vials. The solution was stirred on a magnetic stir plate for 10 minutes and sonicated for 30 minutes before use. Approximately 100 μm thick films containing the water soluble coating formulations in Table 2 were prepared using the method described in Example 1. The prepared film was sealed between two aluminum plates in a compression molding machine under a force of 5000 psi for 1 minute. The seal strength of the sealing solution was characterized as >11N using the method specified in ASTM F88.

[0053] Table 4. Seal Strength of Sealing Solutions.

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com