Machining device for producing spare and accessory parts of textile machinery

A technology for textile machinery and processing devices, which is applied in the field of processing devices for the production of textile machinery spare parts. It can solve the problems of inconvenient rapid positioning of spare parts of different specifications, easy to be affected by external vibration force, increased defective rate and cost, etc. problems, to achieve the effects of simple structure, improved processing accuracy, reduced defective rate and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

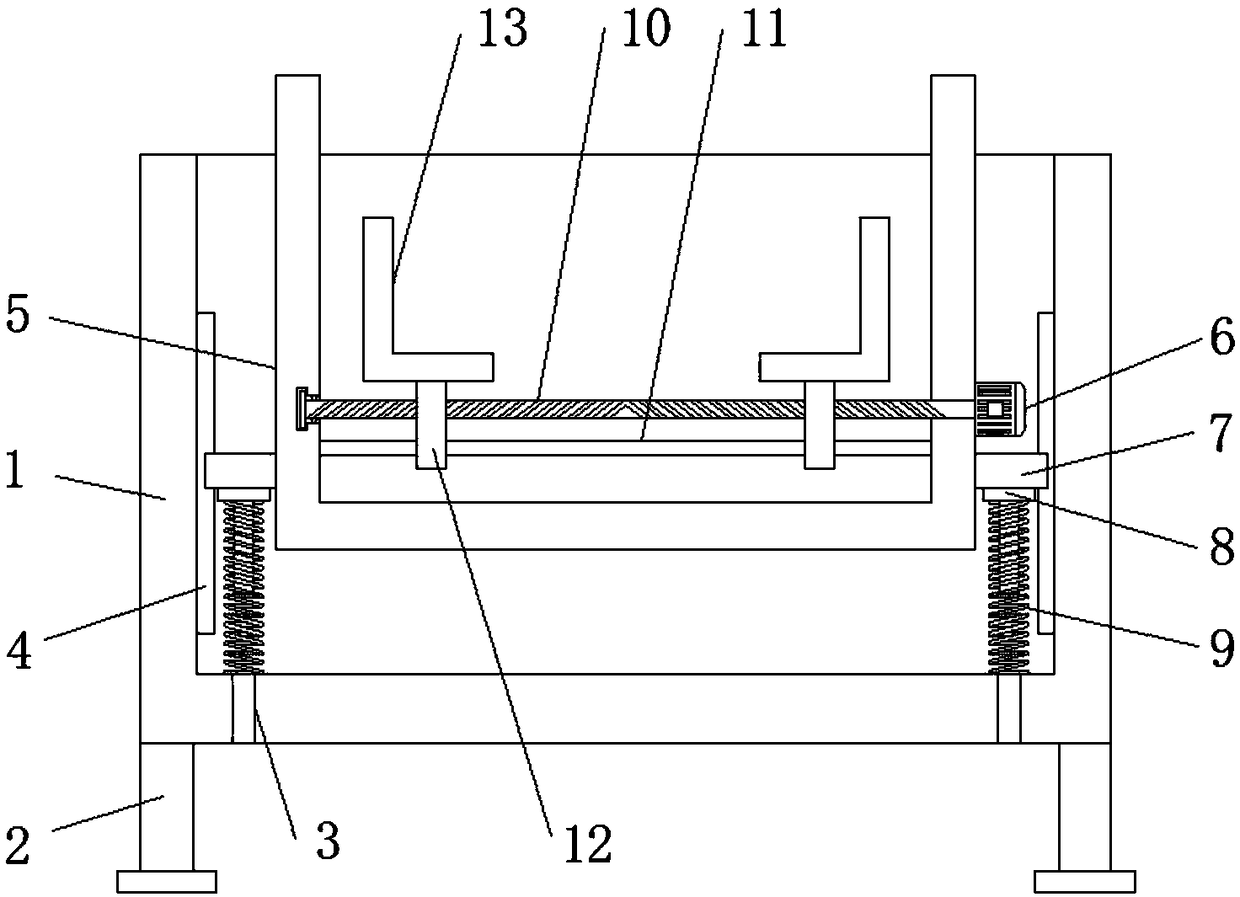

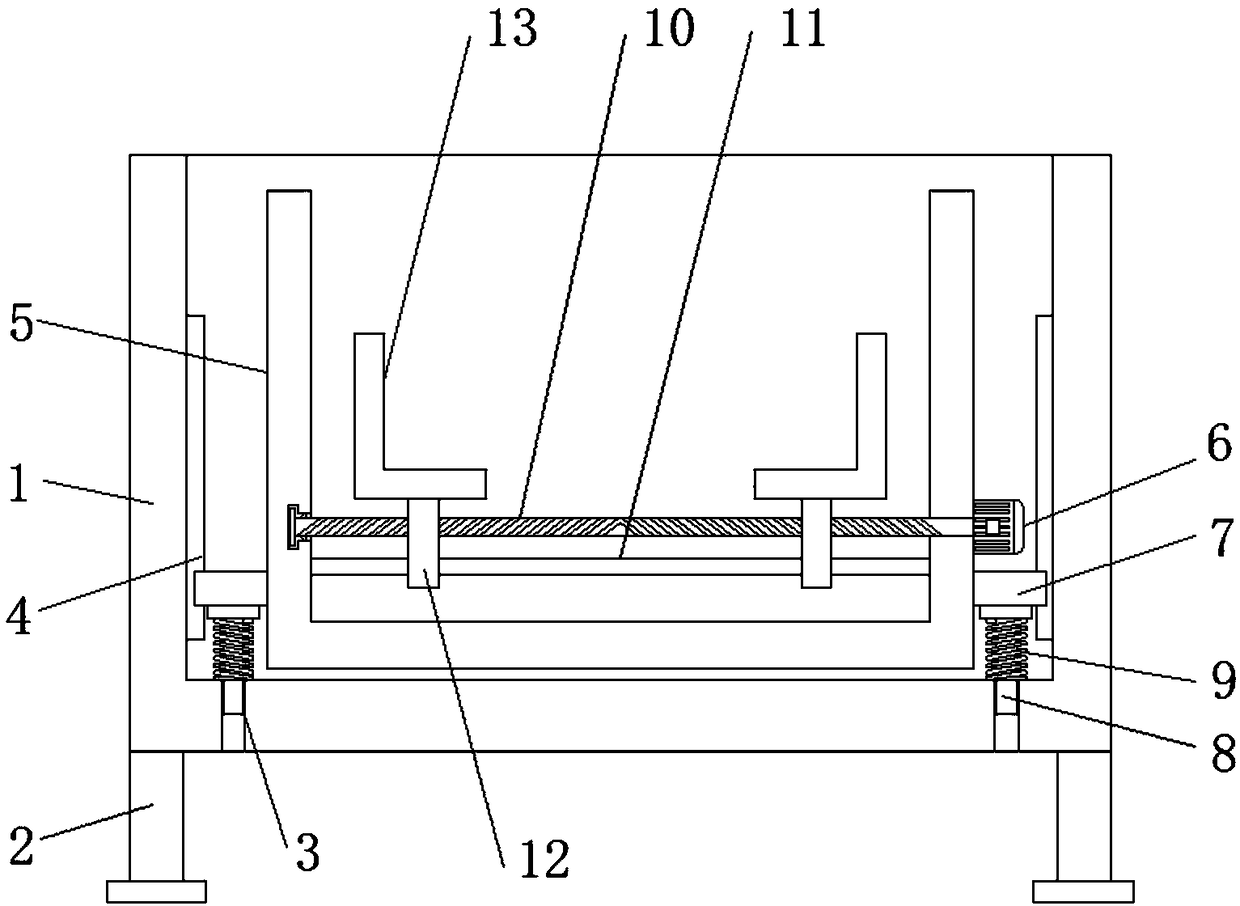

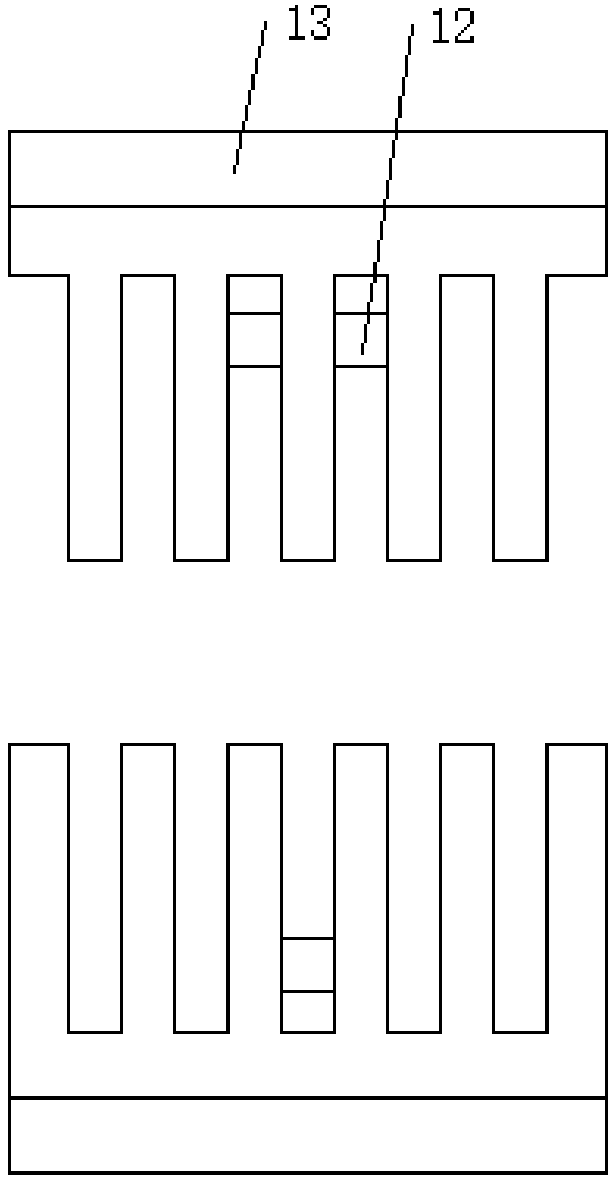

[0019] refer to Figure 1-3 , a processing device for the production of textile machinery spare parts, comprising a device body 1, the device body 1 is a cavity structure, both sides of the bottom of the device body 1 are equipped with outriggers 2, and both sides of the bottom of the device body 1 are provided with The movable port 3 connected to the inner cavity of the device body 1, the inner middle position of the device body 1 is provided with a movable bracket 5, a bidirectional motor 6 is installed on one side outer wall of the movable bracket 5, and horizontal motors 6 are installed on both sides of the movable bracket 5. The positioning plate 7 provided, the bottom of the positioning plate 7 is welded with a guide vertical bar 8, the guide vertical bar 8 is sleeved with a spring 9, and one end of the spring 9 is fixedly connected with the inner inner wall of the device body 1, and the internal connection of the movable support 5 There are threaded crossbars 10 and sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com