A passive compliant joint with variable stiffness based on elastic elements

An elastic element and joint technology, applied in the field of variable stiffness passively compliant joints, can solve problems such as poor dynamic performance and increase energy loss, and achieve the effects of reducing energy loss, increasing natural frequency, and increasing frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

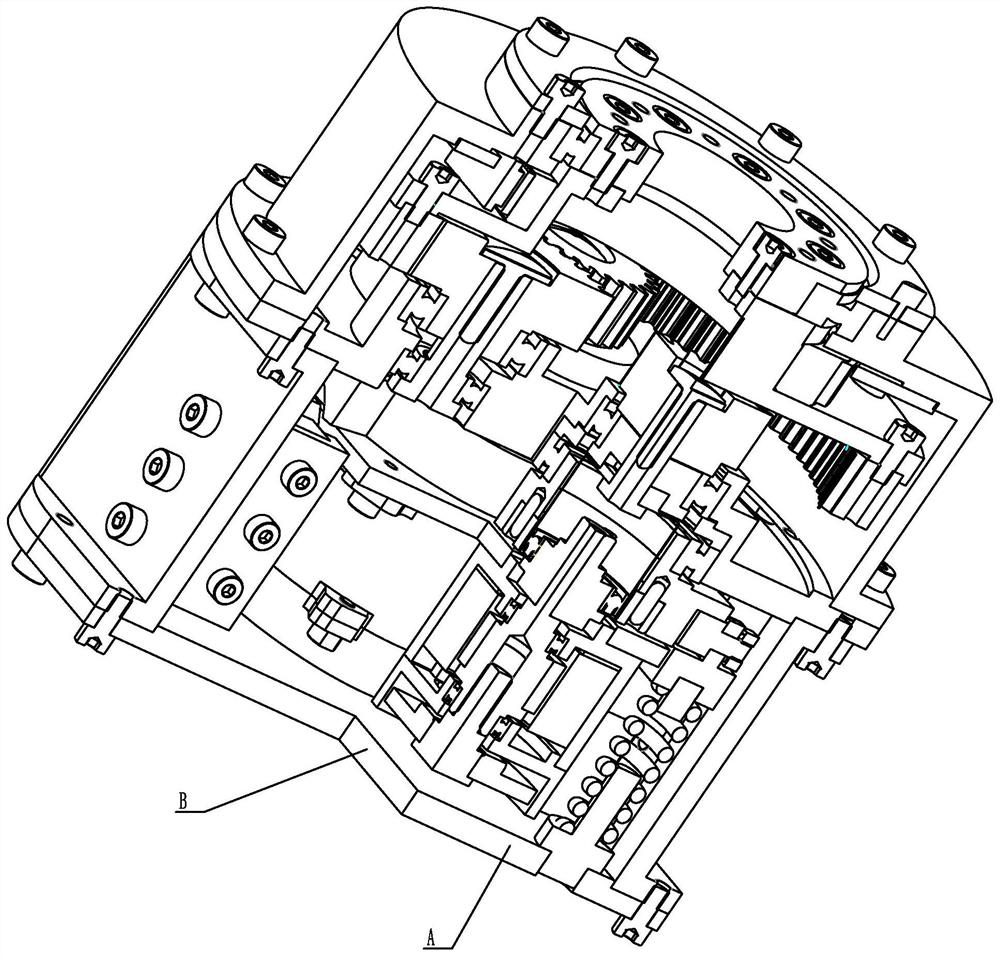

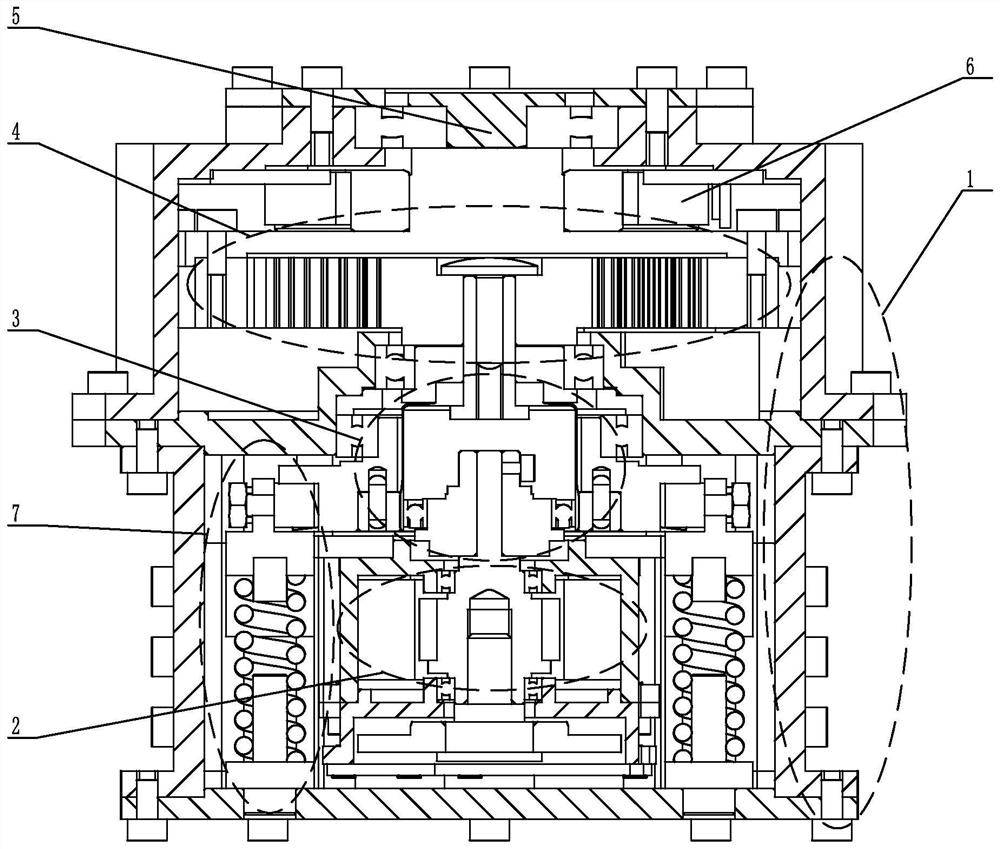

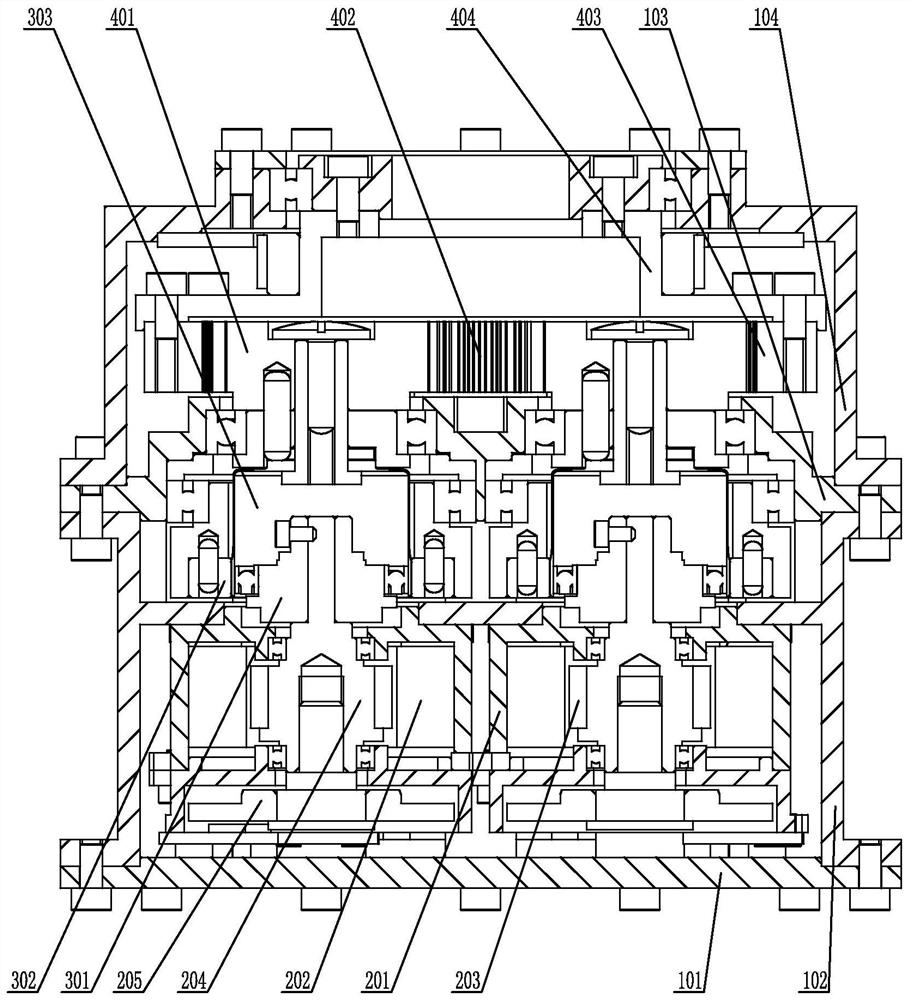

[0020] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment. A variable stiffness passive compliant joint based on elastic elements in this embodiment includes a joint housing 1, a gear transmission mechanism 4, a joint output 5, a magnetic encoder 6 at the joint end, two joint motors 2, Two harmonic reducers 3 and two stiffness adjustment mechanisms 7, the joint motor 2 are symmetrically fixed inside the joint housing 1, the gear transmission mechanism 4 includes an output end and two input ends, and the motor shaft 204 of the joint motor 2 The harmonic reducer 3 is connected to the input end of the gear transmission mechanism 4, the output end of the gear transmission mechanism 4 is connected to the joint output 5, the magnetic encoder 6 at the joint end is connected to the gear transmission mechanism 4, and both sides of the harmonic reducer 3 A stiffness adjustment mechanism 7 is symmetrically provided.

specific Embodiment approach 2

[0021] Specific implementation mode two: combination Figure 1 to Figure 4 To describe this embodiment, the joint motor 2 in this embodiment further includes a motor housing 201 , and the motor housing 201 is fixedly connected to the joint housing 1 . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination Figure 1 to Figure 4 Describe this embodiment, the joint motor 2 described in this embodiment also includes a stator 202, a rotor 203 and a motor end magnetic encoder 205, the stator 202 is fixed inside the motor housing 201, the rotor 203 is arranged inside the stator 202, and the rotor 203 Rotating relative to the stator 202 , the motor end magnetic encoder 205 is arranged inside the motor housing 201 and connected to the motor shaft 204 . Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com