An ecm motor and its applied hvac system

A motor controller and circuit technology, applied in the field of HVAC system, can solve the problems of inability to realize low-speed operation of HVAC system, complex debugging control board, high power consumption and noise, etc., to improve market competitiveness, simple structure, and system power consumption. and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

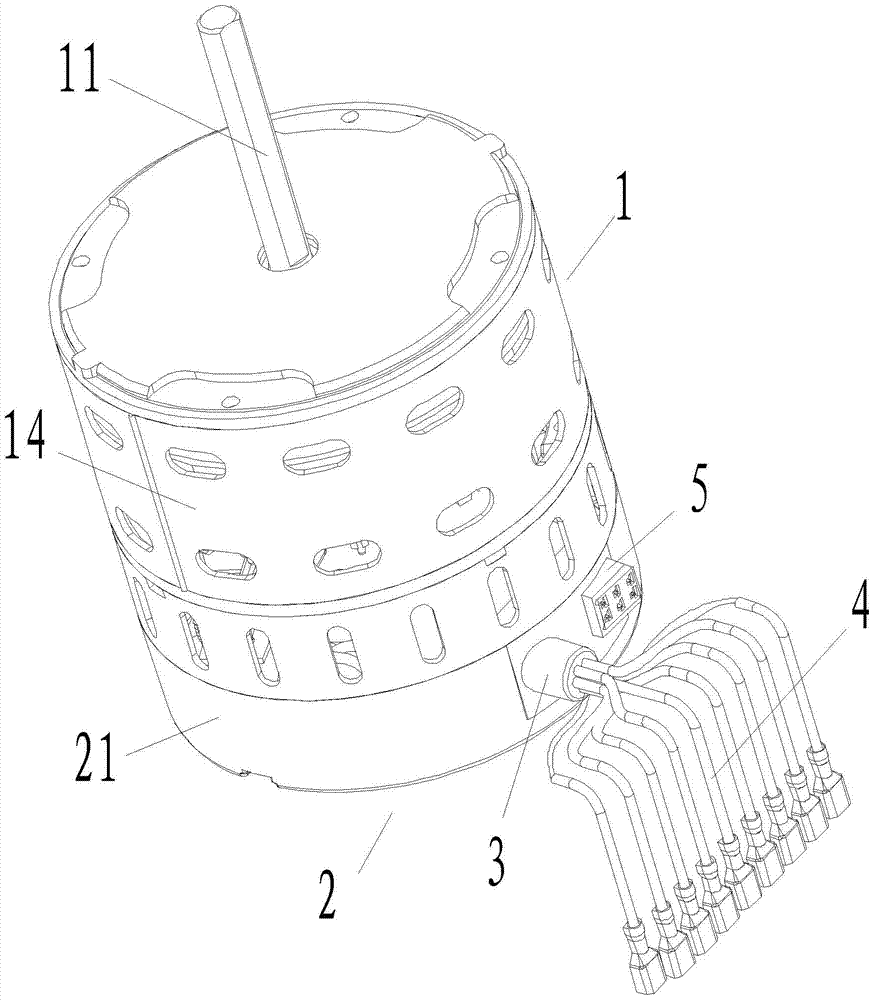

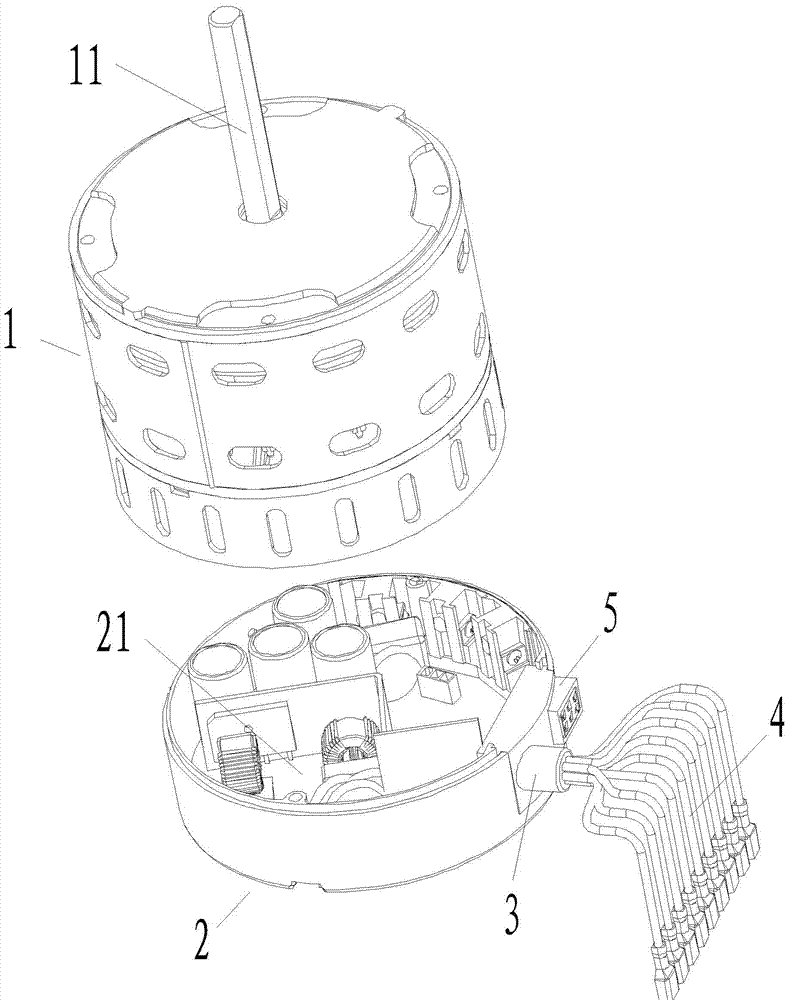

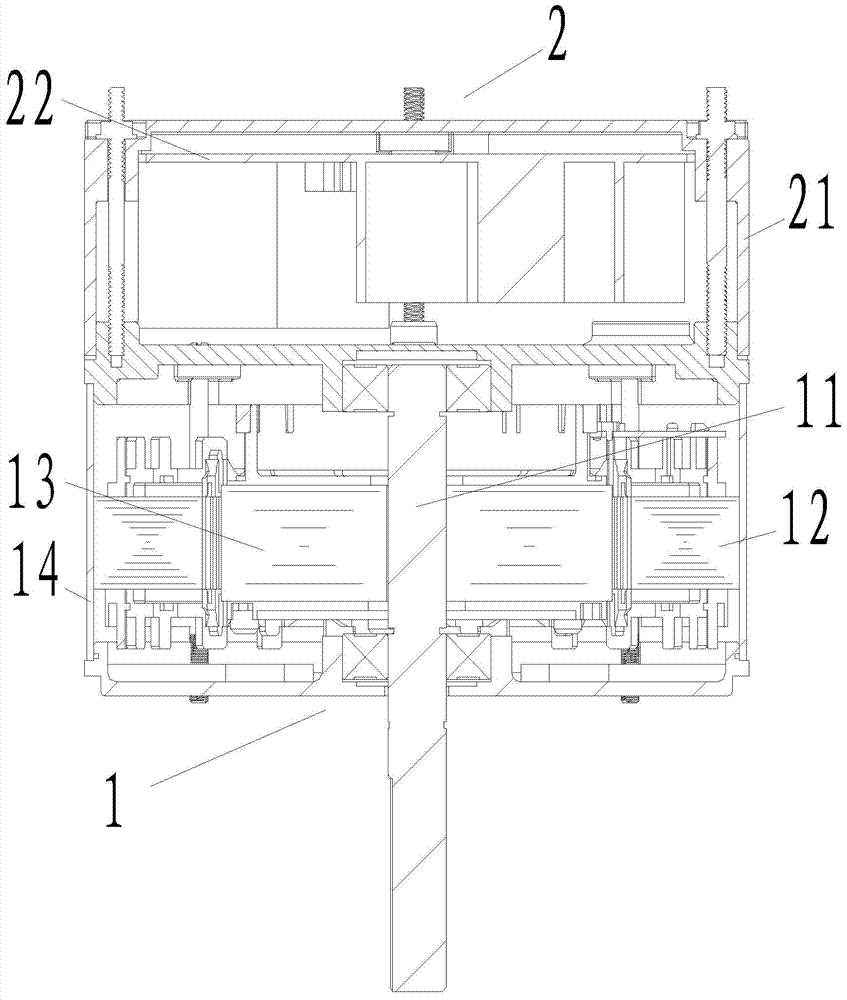

[0056] Embodiment one: if figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention is an ECM motor. The ECM motor includes a motor 1 and a motor controller 2. The motor 1 includes a rotating shaft 11, a stator assembly 12, a rotor assembly 13 and a housing assembly 14. The rotor assembly 13 is installed on the rotating shaft 11 Above, the stator assembly 12 and the shell assembly 14 are installed together and nested outside the rotor assembly 13. The motor controller 2 includes a control box 21 and a control circuit board 22 installed inside the control box 21. The control circuit board 22 is integrated with micro Processor, inverter circuit, gear detection circuit, memory and power supply part, the power supply part is connected to the external AC power input, the output end of the power supply part supplies power to each part of the circuit, and the rotor position detection circuit detects the rotor position of the motor through the Hall ...

Embodiment 2

[0095] Embodiment two: if Figure 1 to Figure 12 As shown, the present invention is a kind of HVAC system, described HVAC system replaces original PSC fan motor with ECM motor, described HVAC system comprises thermostat THERMOSTAT, HVAC system controller, wherein:

[0096] The ECM motor includes a motor controller 2 and a motor 1, and the motor controller 2 drives the motor 1 to run. The motor controller 2 includes a control box 21 and a control circuit board 22 installed in the control box 21. The control circuit board 22 is integrated with a microprocessor, an inverter circuit, a gear detection circuit, a memory and a power supply part. The power supply part is connected to the input of an external AC power supply. input line;

[0097] The thermostat THERMOSTAT has two 24V AC power input terminals (R, C), at least one cooling signal output port, at least one heating signal output port and a continuous fan mode signal output port G, wherein the cooling signal output port and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com