In-mould printing method for blow-molded thin-wall container

A thin-walled container, blow molding technology, applied in metal processing and other directions, can solve problems such as high cost and complex process steps, and achieve the effects of high production efficiency, simple process, and high production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

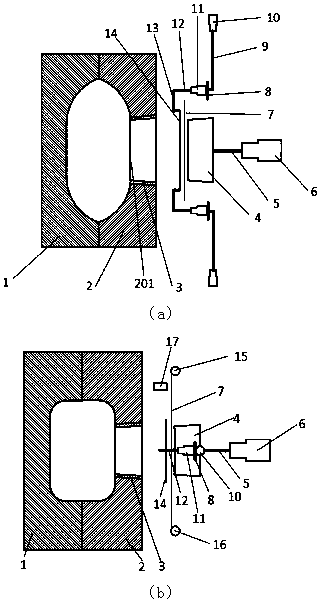

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

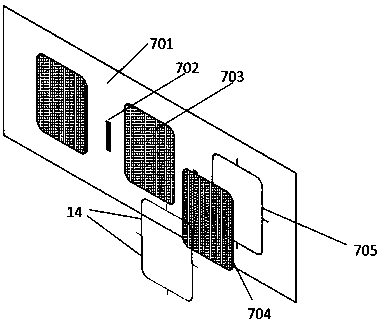

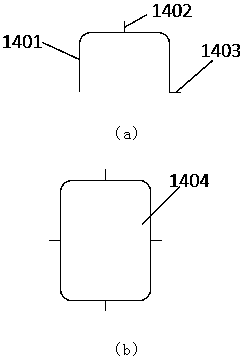

[0033] The invention provides an in-mold printing method for blow-molded thin-walled containers, which realizes the structure as Figure 1-4 As shown, the in-mold printing of thin-walled injection molded products is realized through cyclic operation, and the cyclic process includes the following steps:

[0034] (1) The winding motor 15 is running, driving the label roll 7 to move at a constant speed, and the damping unwinding wheel 16 generates a slight resistance torque to prevent the label roll 7 from wrinkling or wavy. When the photoelectric positioner 17 scans the label roll Positioning stripes 702 on 7, the winding motor stops, at this time, the pattern area on the label roll 7 coincides with the projection of the front end surface 402 of the wedge-shaped die 4;

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com