Vacuum tank detection anti-explosion device

An explosion-proof device and vacuum tank technology, applied in the layout of reservoirs, brake safety systems, etc., can solve the problems of complex devices, high production costs of explosion-proof detection devices, and low safety performance of pressure detection, and achieve convenient operation, simple structure, Check the effect of high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

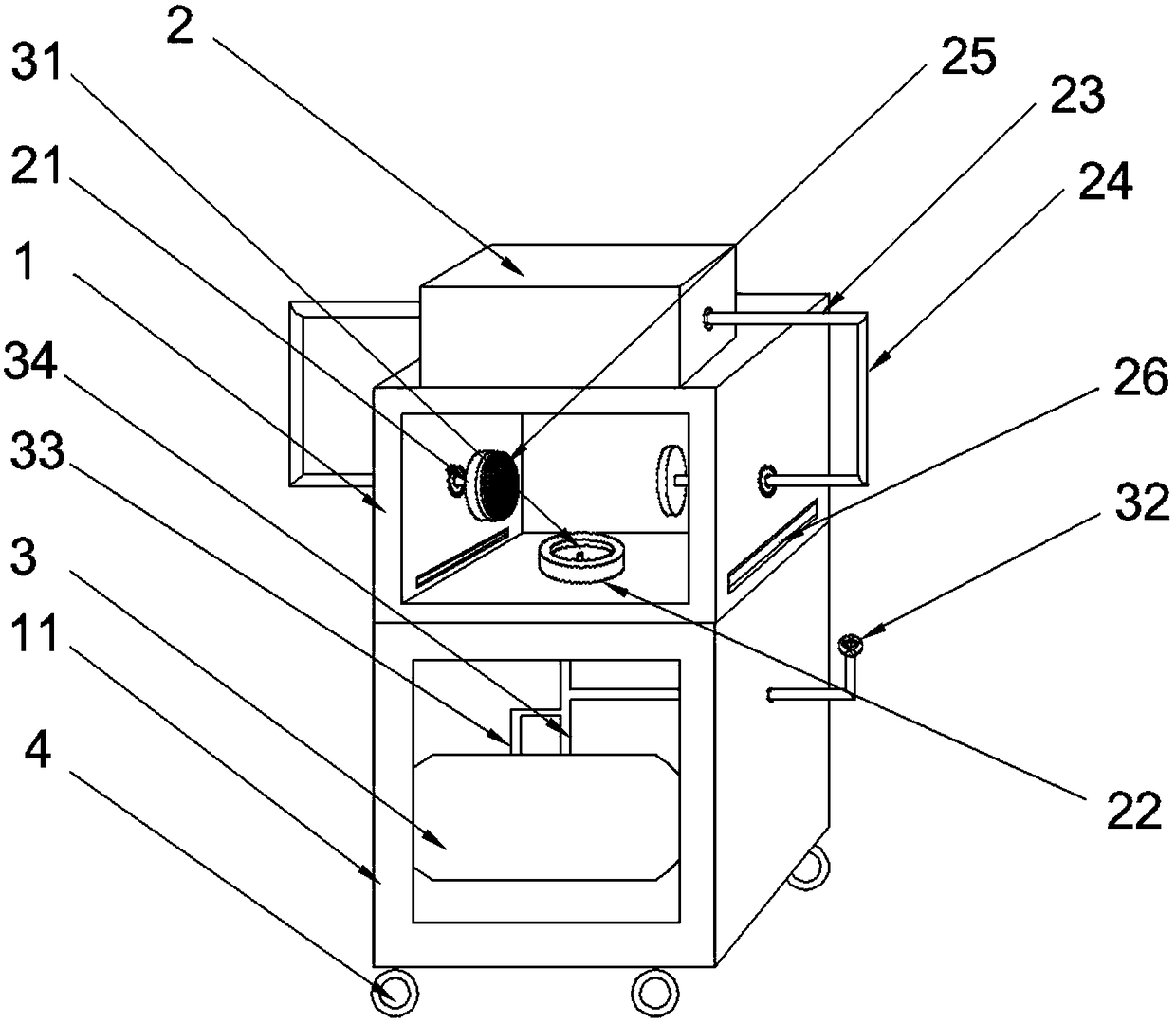

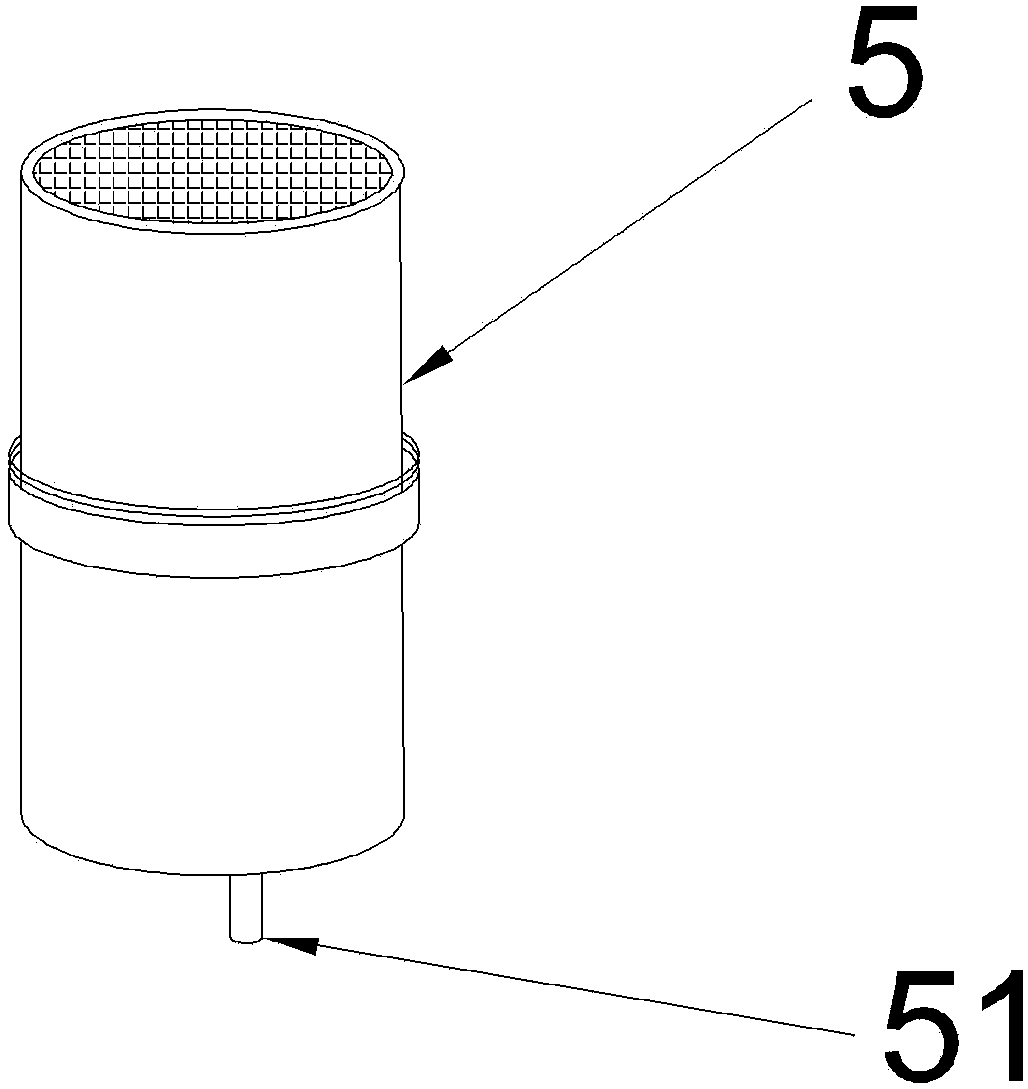

[0020] Embodiment 1 discloses a vacuum tank detection explosion-proof device, such as Figure 1-3 As shown, it includes a box frame, a vacuum tank fixing device and an air pump 3. The vacuum tank fixing device is fixedly installed on the box frame, and the air pressure pump 3 is arranged in the inner cavity of the box frame. During work, the vacuum tank 5 is carried out by the vacuum tank fixing device. Fixed, the joint 31 of the air pump 3 is connected with the air inlet 51 of the vacuum tank 5, and the pressure of the vacuum tank 5 is detected by the air pump 3. Wherein the box frame in the present embodiment is formed by connecting the upper box body 1 and the lower box body 11; Fixedly installed on the top of the upper box body 1, a pair of fixed plates 21 are arranged relatively parallel to the inner cavity of the upper box body 1, and the pair of fixed plates 21 are respectively connected to the piston rods 23 at both ends of the double-rod hydraulic cylinder 2 through L...

Embodiment 2

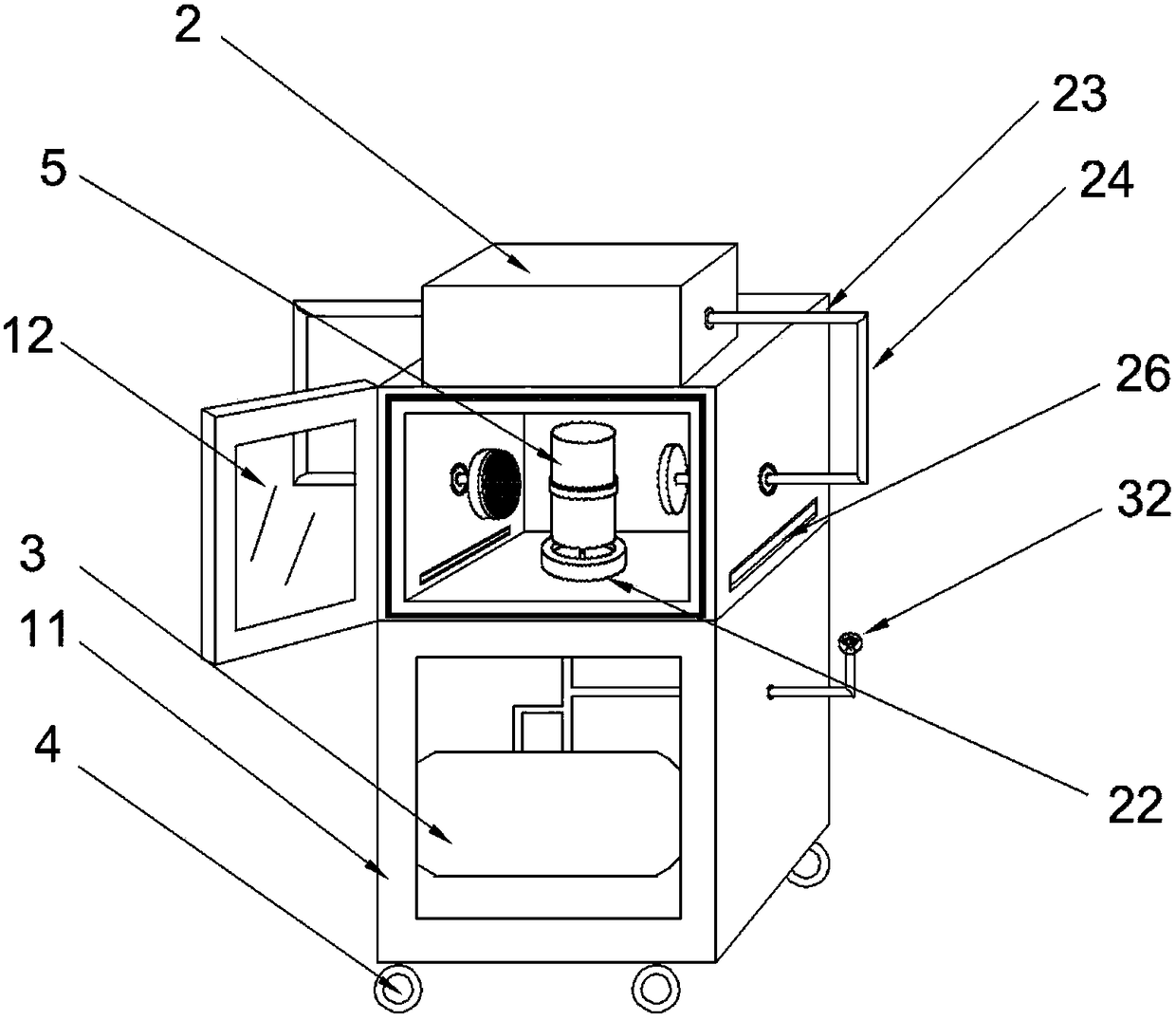

[0022] Embodiment 2 discloses a vacuum tank detection explosion-proof device, including a box frame, a vacuum tank fixing device and an air pressure pump 3, the vacuum tank fixing device is fixedly installed on the box frame, and the air pressure pump 3 is arranged in the inner cavity of the box frame. , the vacuum tank 5 is fixed by the vacuum tank fixing device, the joint 31 of the air pump 3 is connected with the air inlet 51 of the vacuum tank 5, and the pressure of the vacuum tank 5 is detected by the air pump 3. Wherein the box frame in the present embodiment is formed by connecting the upper box body 1 and the lower box body 11; Fixedly installed on the top of the upper box body 1, a pair of fixed plates 21 are arranged relatively parallel to the inner cavity of the upper box body 1, and the pair of fixed plates 21 are respectively connected to the piston rods 23 at both ends of the double-rod hydraulic cylinder 2 through L-shaped connecting rods 24 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com