Preparation process of zinc acetylacetonate

A technology of zinc acetylacetonate and preparation process, which is applied in the preparation of aldehyde/ketone chelate compound, organic chemistry and other directions, can solve the problems of large investment and high maintenance cost, and achieves the effects of easy operation, few by-products, simple and efficient process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

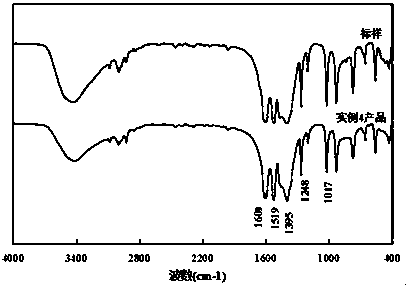

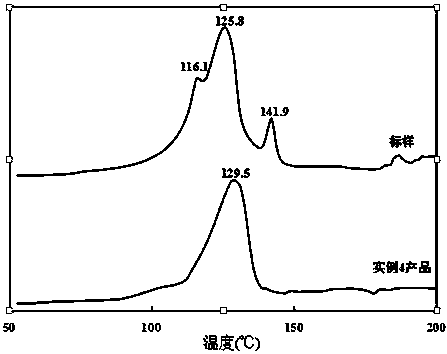

Examples

example 1

[0026] Add 400g of acetylacetone into the three-necked flask, heat up to 90°C-100°C, weigh 160g of zinc oxide and add it into the three-necked flask at a stirring rate of 150rpm, continue to heat up to 110°C-120°C, add 1g of water and mix for 30 minutes to produce material, after crushing, the white powder product of zinc acetylacetonate can be obtained. The yield of zinc acetylacetonate obtained was 95.7%, the zinc content was 25.2%, and m.p.129.8°C.

example 2

[0028] Add 1000g of acetylacetone into the three-necked flask, heat up to 90°C-100°C, weigh 395g of zinc oxide and add it into the three-necked flask at a stirring rate of 180rpm, continue to heat up to 115°C-125°C, add 5g of hydrogen peroxide and mix for 30 minutes to produce material, after crushing, the white powder product of zinc acetylacetonate can be obtained. The yield of zinc acetylacetonate obtained was 94.9%, the zinc content was 25.6%, and m.p.131.4°C.

example 3

[0030] Add 2000g of acetylacetone into the three-necked flask, heat up to 90°C-100°C, weigh 780g of zinc oxide and add it into the three-necked flask at a stirring rate of 200rpm, continue to heat up to 120°C-130°C, add 8g of glacial acetic acid and mix for 30 minutes. After discharging and pulverizing, the white powder product of zinc acetylacetonate can be obtained. The yield of zinc acetylacetonate obtained was 94.3%, the zinc content was 25.9%, and m.p.132.6°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com