Al-Mn-Si-Mg alloy material and preparation method thereof

An alloy material and preparation method technology, applied in the field of metal materials and metallurgy, can solve the problems of difficult reuse of composite strip waste, easy to exceed the impurity content, difficult to control alloy composition, etc., and achieve good application prospects, excellent product performance, and lightening. the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

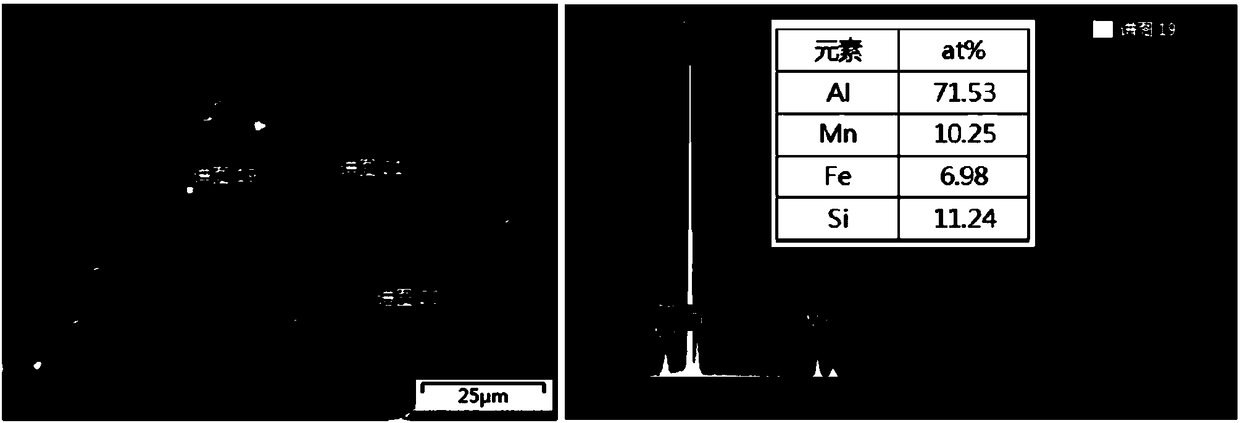

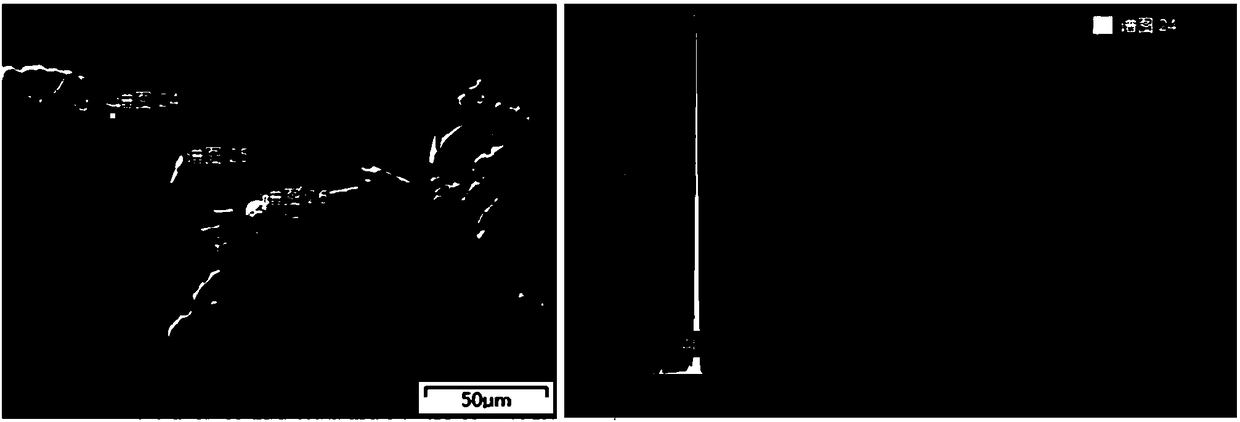

Image

Examples

Embodiment 1

[0036] Dry the waste produced in the production process of the composite strip to remove moisture, and then smelt it to form a waste melt; control its composition by weight percentage to contain Mn 1.35%, Si 1.35%, Fe≤0.8%, Mg 1.35%, Cu 0.25%, Cr0 .35%, Zn 0.45%, Ti 0.15%, the balance is Al, wherein the impurity content is ≤1.0%; control the melting temperature to 750°C, after all the materials are melted, stir evenly to obtain aluminum alloy melt;

[0037] Use a rotary blowing device to blow the refining agent into the aluminum alloy melt for refining treatment. The refining agent is Promag granular refining agent. Pouring after slag removal, on-line degassing and on-line addition of grain refiner during the pouring process, filtering and pouring into round rods through ceramic plates;

[0038] Put the round bar into the homogenization furnace for homogenization treatment, the temperature is 530°C, and the time is 16h;

[0039]Preheat the round bar after homogenization treat...

Embodiment 2

[0042] Method is with embodiment 1, and difference is:

[0043] (1) Use waste materials to account for 80% of the total weight of all raw materials, add aluminum ingots and master alloys to the waste material melt, and the melt control components contain Mn 1.18%, Si 1.05%, Fe≤0.8%, Mg 1.2% by weight percentage , Cu 0.25%, Cr0.28%, Zn0.36%, Ti 0.15%; melting temperature is 745°C;

[0044] (2) The amount of refining agent is 0.25% of the total weight of the aluminum alloy melt; after the refining treatment, it is left to stand for 35 minutes, filtered and cast into a round rod through a ceramic plate;

[0045] (3) Homogenization treatment temperature 520°C, time 24h;

[0046] (4) Extrude the homogenized round bar after preheating, and quench it online; then age at 150°C for 24 hours, and finally obtain the Al-Mn-Si-Mg alloy profile;

[0047] (5) The T6 tensile strength of the product is 309MPa, and the elongation is 7.8%.

Embodiment 3

[0049] Method is with embodiment 1, and difference is:

[0050] (1) Use waste materials to account for 80% of the total weight of all raw materials, add aluminum ingots and master alloys to the waste material melt, and the melt control components contain Mn 1.15%, Si 1.02%, Fe≤0.8%, Mg 0.9% by weight percentage , Cu 0.2%, Cr0.25%, Zn 0.35%, Ti 0.12%; the melting temperature is 740°C;

[0051] (2) The amount of refining agent is 0.2% of the total weight of the aluminum alloy melt; after the refining treatment, let it stand for 30 minutes, filter and cast it into a flat ingot through a ceramic plate;

[0052] (3) Homogenization treatment temperature 550°C, time 12h;

[0053] (4) Remove the skin of the slab after the homogenization treatment, and roll it into a plate; the plate is first solution treated at 520° C. for 3 hours, and then aged at 150° C. for 24 hours; finally, an Al-Mn-Si-Mg alloy plate is obtained;

[0054] (5) The T6 tensile strength of the product is 305MPa, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com