Ultra high strength low temperature ductile iron casting for wind turbine generator and manufacturing method thereof

An ultra-high-strength, wind turbine technology, applied in the direction of improving process efficiency, can solve the problems of qualified low-temperature impact energy at the strength level, and the chemical composition and process angle cannot be improved, and achieve the effect of improving the strength index and lightweight design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

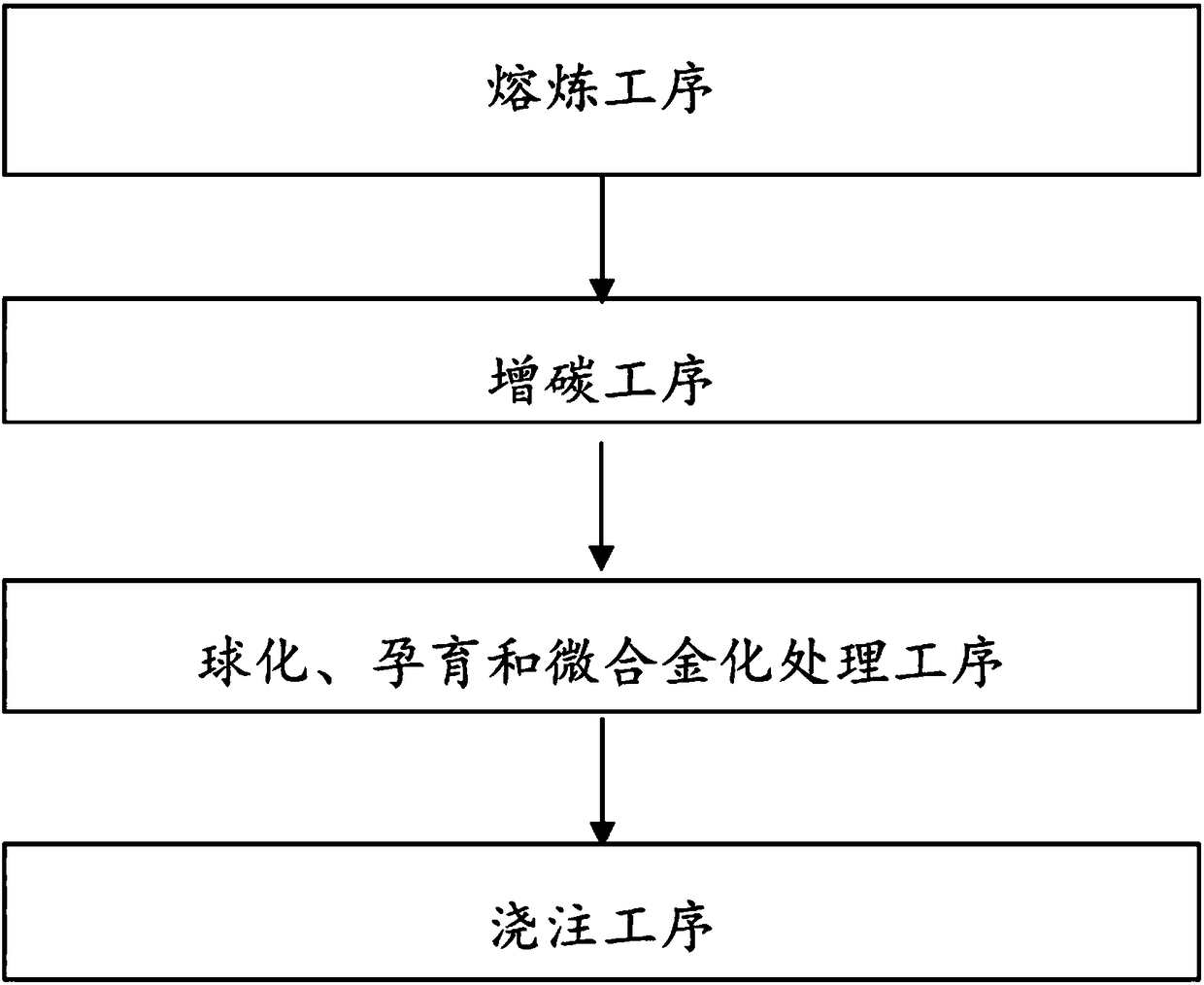

Method used

Image

Examples

Embodiment 1

[0058] A 10T intermediate frequency furnace is used to smelt pig iron, recycled material and scrap steel. The smelting temperature is 1430°C. At this temperature, the molten iron is carburized in the electric furnace. Lay the inoculant on one side of the dam in the 1T spheroidizing bag, and lay the nodulizer, recarburizer, V in the microalloy and Ni in the microalloy on the other side of the dam from bottom to top, and then cover it with cast iron shavings On Ni in the microalloy, the covering thickness is 6-10mm. Add molten iron into the spheroidizing bag from the side of the spheroidizing bag where the inoculant is laid, wherein the additions of the spheroidizing agent and the inoculant are 1.0wt% and 0.4wt% respectively, and the addition of V and Ni in the microalloy The amount is shown in Table 2. The pouring process adopts the secondary inoculation method, and the addition amount of the flow inoculant is 0.15wt%. The components of the obtained ductile iron piece include...

Embodiment 2- Embodiment 5

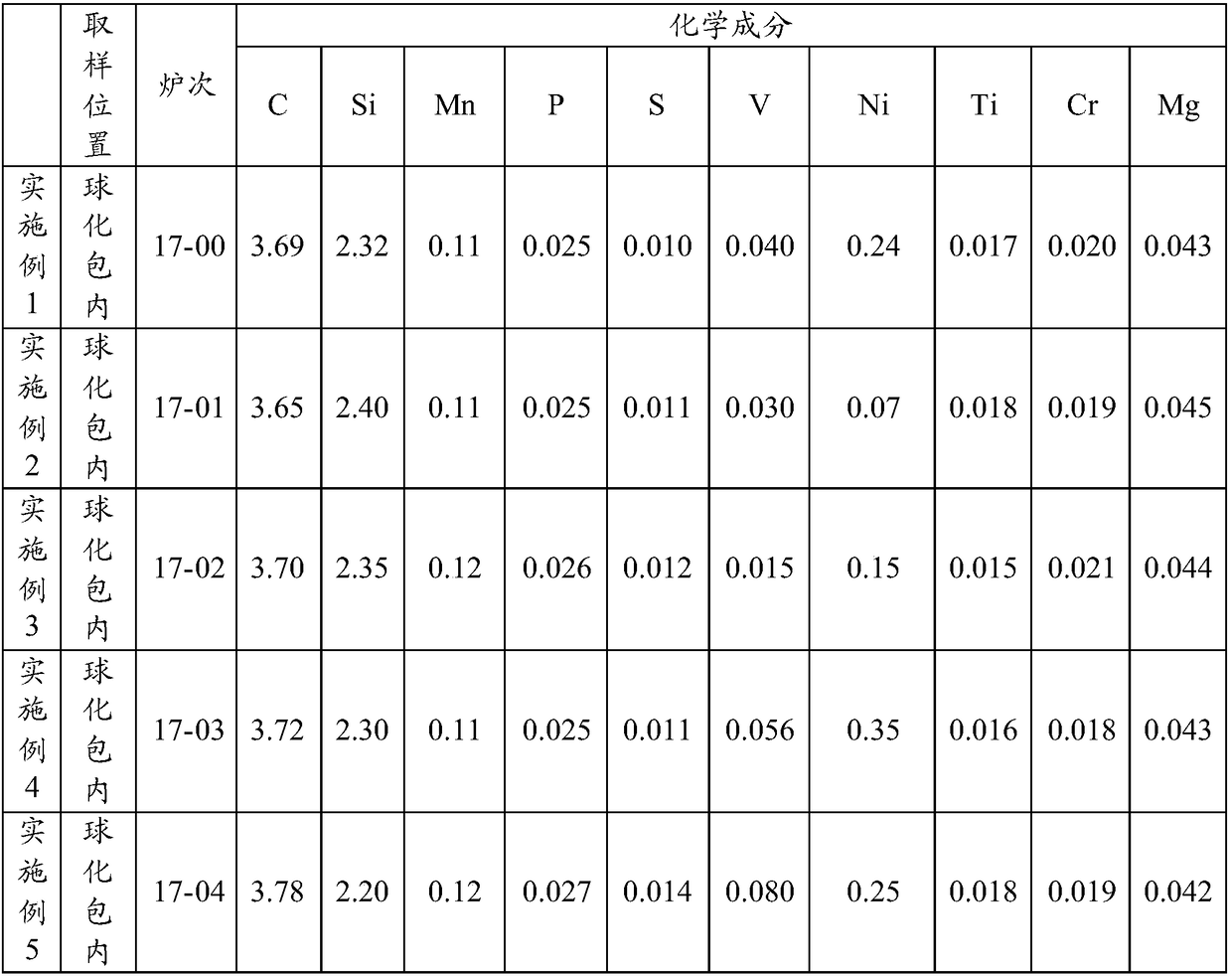

[0060] Ductile iron pieces were prepared according to the method of Example 1 except that the composition of molten iron, nodulizer, inoculant, and flow inoculant were added in different amounts. Table 2 and Table 3 show the component content of molten iron in the spheroidizing ladle of Example 2-Example 5, the addition amount of nodulizer, inoculant and flow inoculant. The mechanical properties of the prepared ductile iron pieces are shown in Table 4.

[0061] Table 2

[0062]

[0063] table 3

[0064]

Nodulizer (wt%)

Inoculants (wt%)

Flowing inoculant (wt%)

Example 1

1.00

0.40

0.15

Example 2

1.10

0.45

0.10

Example 3

1.20

0.48

0.13

Example 4

1.15

0.60

0.20

Example 5

1.17

0.50

0.18

[0065] Table 4

[0066]

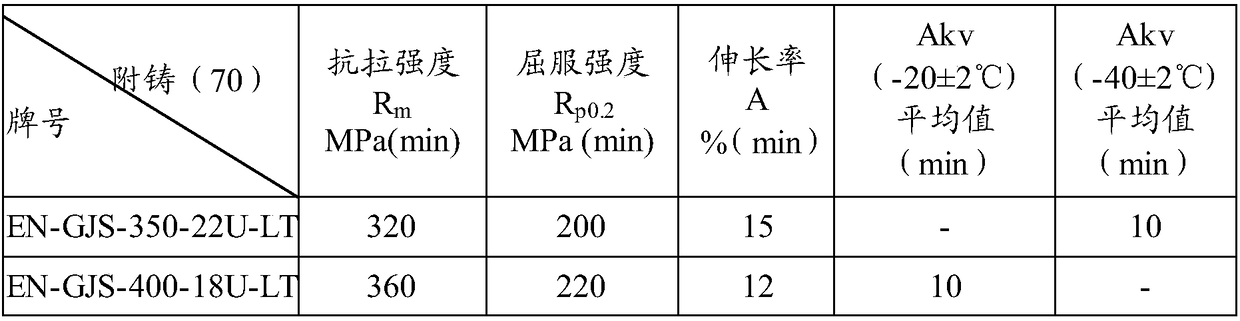

[0067] It can be seen from the above examples that the tensile strength of the ductile iron parts prepared by the method of the present invention is greater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com