Electric heating unit of texturing machine and heating box of texturing machine

A heat unit and heating box technology, applied in textiles and papermaking, etc., can solve the problems of plate shrinkage, large temperature deviation, inconsistent distance between tubes, etc., to reduce heat dissipation area, improve thermal insulation performance, and reduce heat loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

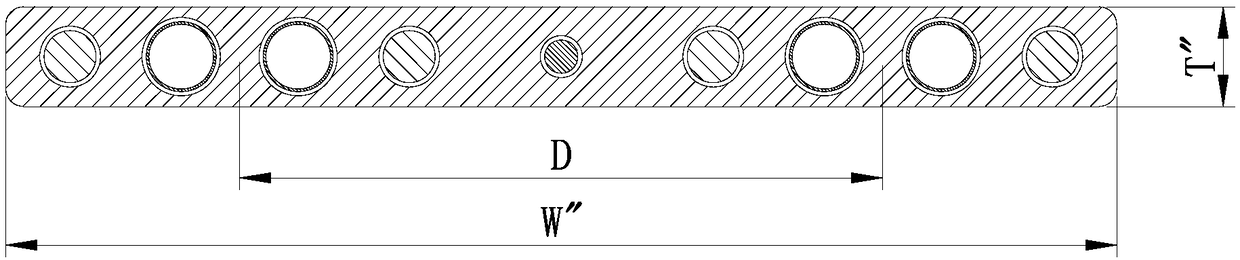

[0050] The difference between the second embodiment of the electrothermal unit of the texturing machine and the first embodiment lies in the distribution of the wire feeding tube 2 , the electric heating tube 3 and the temperature measuring element 4 and the cross-sectional shape of the heat conducting body 1 .

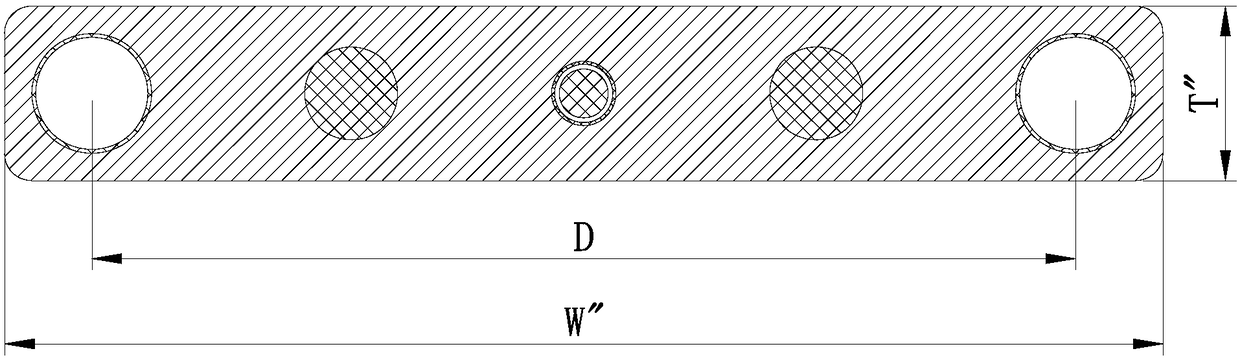

[0051] see Figure 5 , the three-dimensional distribution of the wire tube 2, the electric heating tube 3 and the temperature measuring element 4. Specifically, the wire hole 11, the electric heating hole 12 and the temperature measuring hole 13 are three-dimensionally distributed, the temperature measuring hole 13 is located above the wire hole 11 and the electric heating hole 12, and the axis connection line between the wire hole 11 and the electric heating hole 12 is basically horizontal. Compared with the linear distribution, the three-dimensional distribution can reduce the surface area of the heat conducting body 1 . The distance between the wire feeding hole...

Embodiment 1

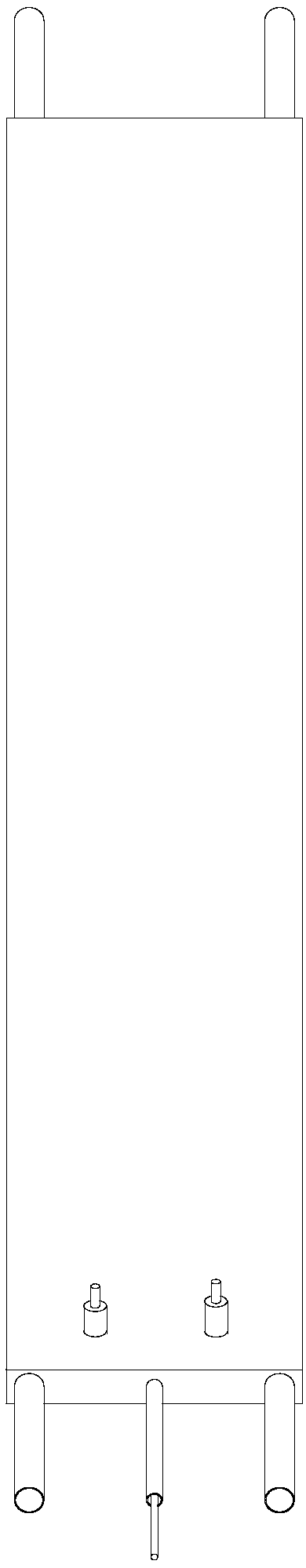

[0060] see Figure 8 , the heating box of the texturing machine, including an electric heating unit and an insulating layer 5 covered by the electric heating unit, and the electric heating unit is the texturing electric heating unit in the second embodiment of the texturing electric heating unit.

[0061] As an improvement of the heating box, the heating box has only one electric heating unit, and the electric heating unit is independently kept warm. A single electric heating unit is independently insulated and made into a pipeline heating box (also called a heating pipeline), which is directly installed in the heating system of the texturing machine. Compared with the original heating box with multiple electric heating plates, the installation of the heating box Maintenance is more convenient and easy.

[0062] As an improvement of the heating box, the insulation layer 5 is a nano-airgel insulation layer 5 , and the nano-aerogel insulation layer 5 is wound on the heat-conduc...

Embodiment 3

[0066] see Figure 11 , the texturing machine heating box, including the electric heating unit and the insulation layer 5 covered by the electric heating unit. As an improvement of the heating box, the heating box also includes a temperature measuring element 4, a control element connected to the temperature measuring element 4, a pressure regulating element controlled by the control element and connected to the electric heating tube 3, and the control element The signal from the temperature element 4 controls the output voltage of the voltage regulating element. Compared with most of the existing technologies that control whether the electric heating tube 3 is working or not by means of a switch, the output voltage of the electric heating tube 3 is controlled by using a voltage regulating element, which can reduce the temperature variation range of the electric heating plate and ensure a higher temperature of the silk path texturing. close to constant.

[0067] Embodiment Fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com