Eddy current testing method of irregular wear-out defect of thimble tube by introducing multimedia units

An eddy current detection and multi-media technology, applied in the direction of material magnetic variables, etc., can solve the problems of a large number of units, increase computing resources, etc., and achieve the effect of improving the reconstruction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

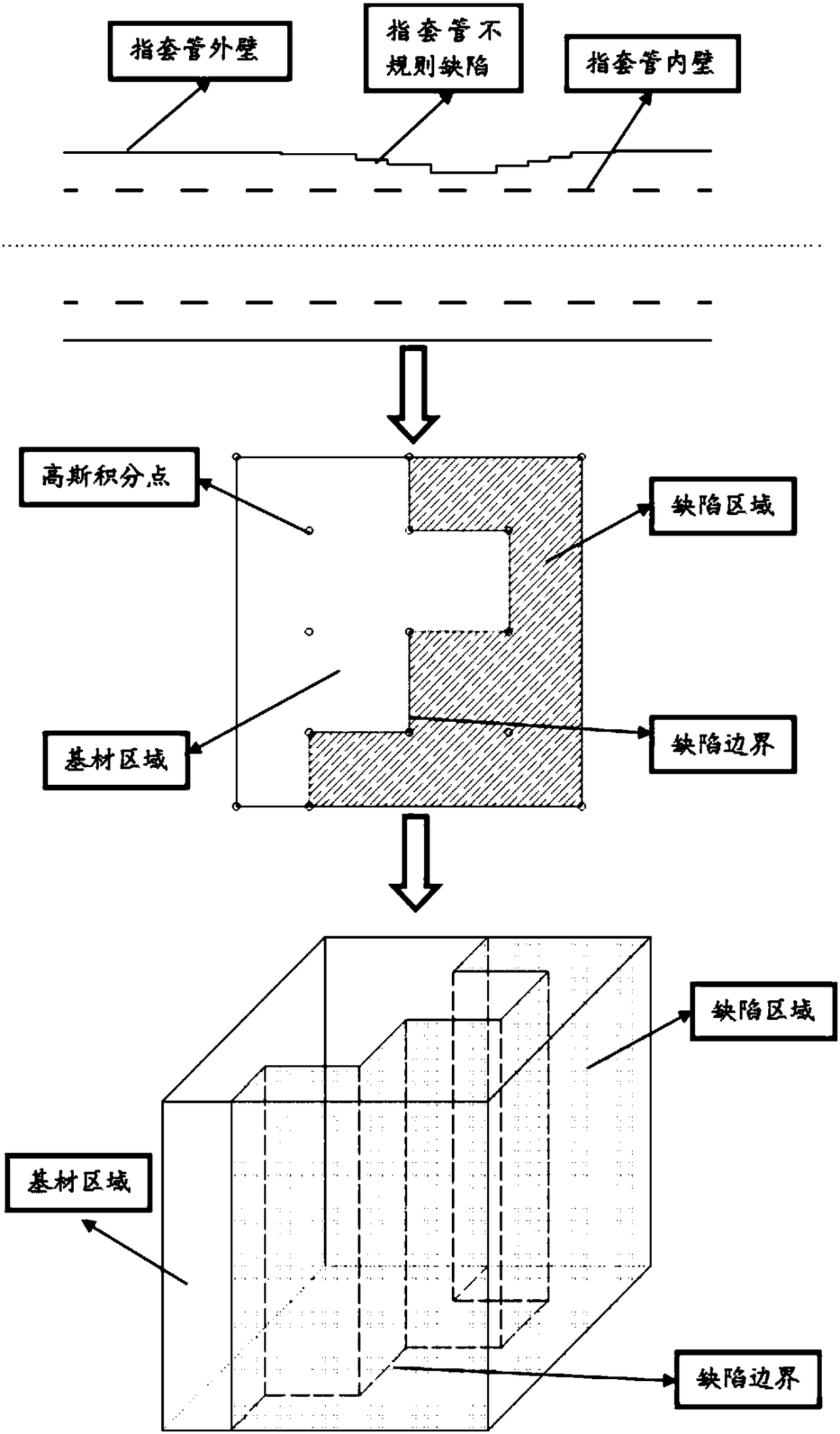

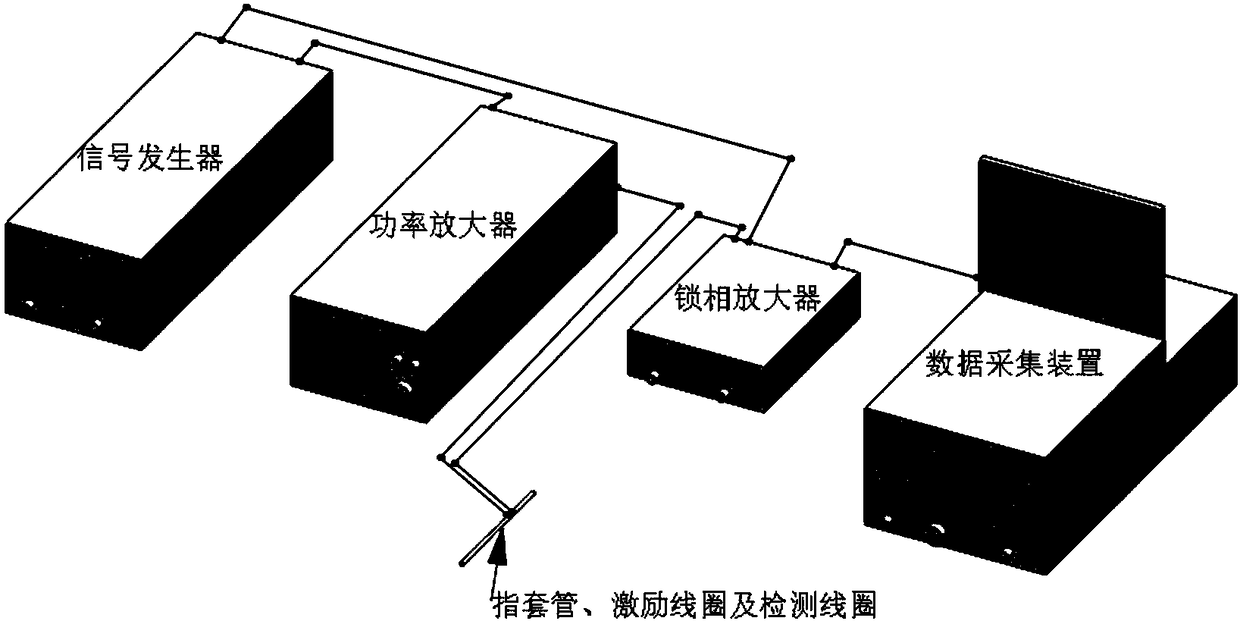

[0049] For such as figure 1 The shown finger sleeve with irregular wear defect and the irregular defect boundary of the multi-media unit based on the Gaussian integration point, the detection steps of the method of the present invention are as follows: figure 2 As shown, turn on the eddy current detection device, generate a certain frequency of excitation current through the signal generator and apply it to the excitation coil. At this time, the excitation coil generates an alternating magnetic field in the three-dimensional space and induces eddy current in the finger sleeve, and the secondary generated by the eddy current The generated magnetic field will change the impedance of the detection coil, and the voltage in the detection coil will change accordingly. The signal from the detection coil is amplified by a lock-in amplifier and then en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com