Battery water content prediction method

A prediction method and technology for water content, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of complex and expensive instrument structure, consumption of a large number of samples and reagents, and complicated operation, so as to improve the setting and accuracy of baking parameters. High, predicting method fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) The establishment of the relationship between air pressure cycle time and water content:

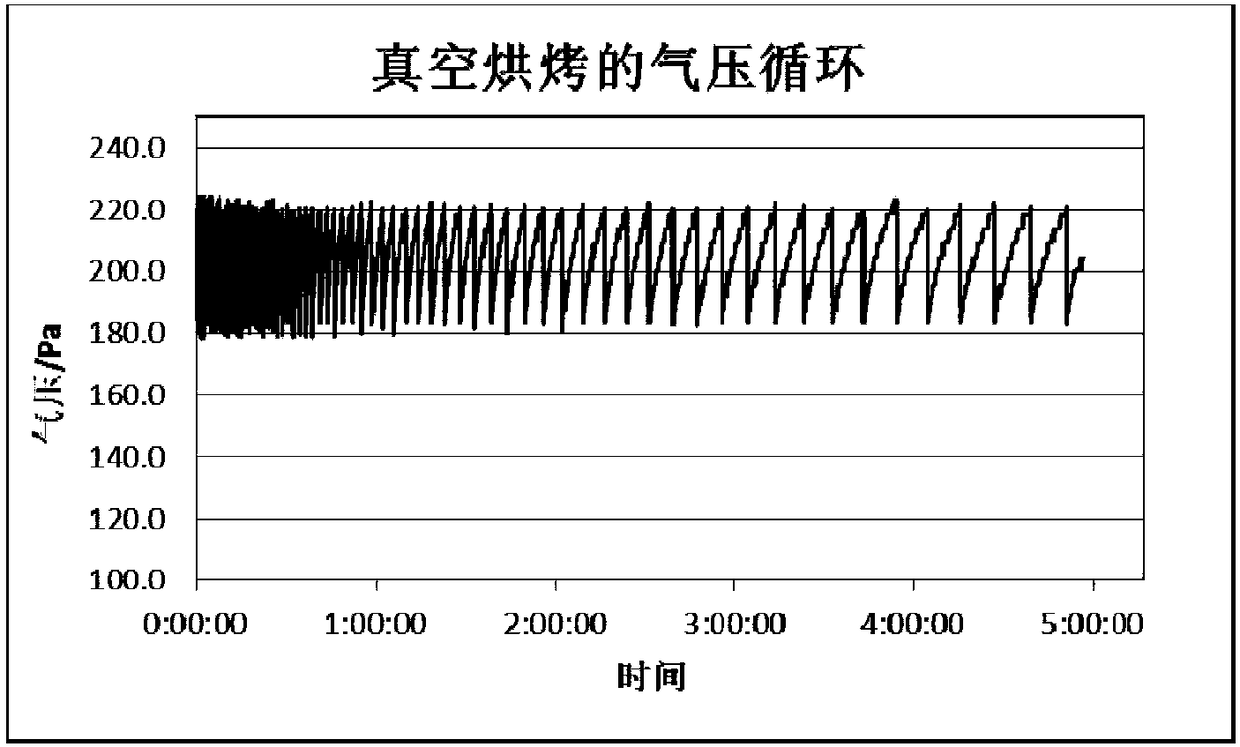

[0032] a. Choose 136 LFP batteries with the model number 2790148 (length*width*thickness: 148mm*90mm*27mm), put them in a vacuum oven and preheat them at 95°C for 1 hour, and set the high and low air pressure as 220Pa and 200Pa, the segmental air pressure vacuum baking time is 5 hours, record the baking time and air pressure value, and obtain the air pressure cycle curve of the segmental air pressure vacuum baking;

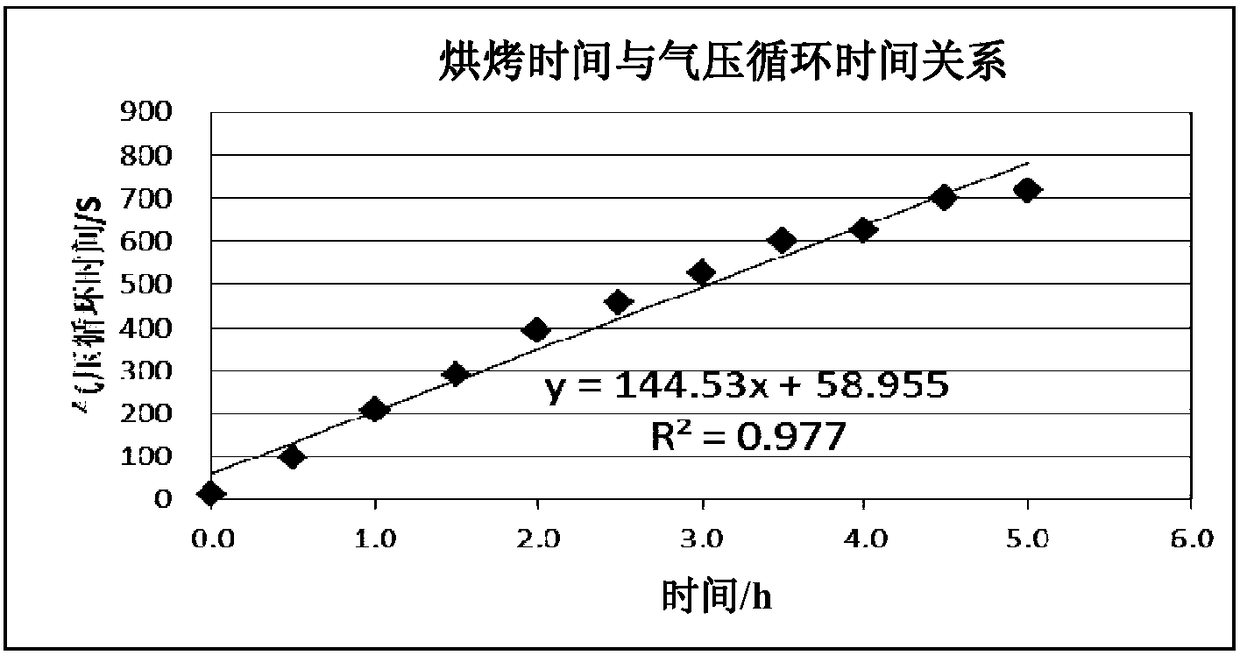

[0033] b. Use the baking time and air pressure value to obtain the discrete data of each group of baking time and air pressure cycle time, and combine Excel processing to obtain the relationship between baking time and air pressure cycle time;

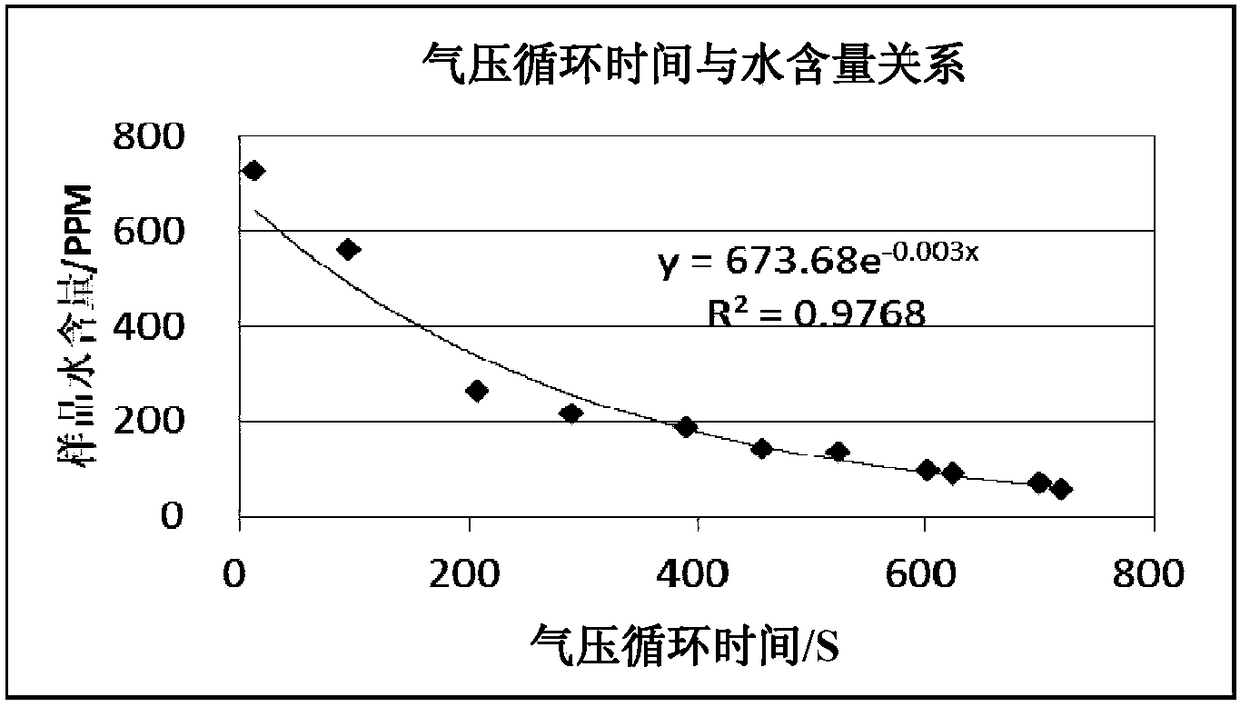

[0034]c. Measure the water content at each baking time by a Karl Fischer moisture analyzer, and the air pressure cycle time at each baking time can be obtained through the relationship between the baking time and the air p...

Embodiment 2

[0038] (1) The establishment of the relationship between air pressure cycle time and water content:

[0039] a. Choose 136 NCM batteries with model number 2790148 (length*width*thickness: 148mm*90mm*27mm), put them in a vacuum oven and preheat them at 95°C for 1 hour, and set the high and low air pressure as 220Pa and 200Pa, the segmental air pressure vacuum baking time is 5 hours, record the baking time and air pressure value, and obtain the air pressure cycle curve of the segmental air pressure vacuum baking;

[0040] b. Use the baking time and air pressure value to obtain the discrete data of each group of baking time and air pressure cycle time, and combine Excel processing to obtain the relationship between baking time and air pressure cycle time;

[0041] c. Measure the water content at each baking time by a Karl Fischer moisture analyzer, and the air pressure cycle time at each baking time can be obtained through the relationship between the baking time and the air pres...

Embodiment 3

[0045] (1) The establishment of the relationship between air pressure cycle time and water content:

[0046] a. Choose 136 NCA batteries with model number 2790148 (length*width*thickness: 148mm*90mm*27mm), put them in a vacuum oven and preheat them at 95°C for 1 hour, and set the high and low air pressure as 220Pa and 200Pa, the segmental air pressure vacuum baking time is 5 hours, record the baking time and air pressure value, and obtain the air pressure cycle curve of the segmental air pressure vacuum baking;

[0047] b. Use the baking time and air pressure value to obtain the discrete data of each group of baking time and air pressure cycle time, and combine Excel processing to obtain the relationship between baking time and air pressure cycle time;

[0048] c. Measure the water content at each baking time by a Karl Fischer moisture analyzer, and the air pressure cycle time at each baking time can be obtained through the relationship between the baking time and the air pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com