Transient high-temperature assembly parameter evolution prediction method for countersunk bolt mixed connection structure

A technology of connection structure and prediction method, which is applied in the fields of electrical digital data processing, design optimization/simulation, special data processing applications, etc., can solve the problems of hindering design optimization and large-scale application process, limited research, endangering the structural integrity of aircraft components and so on. Bearing capacity and efficiency and other issues, to achieve good practical application potential, get rid of the test link, save test time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

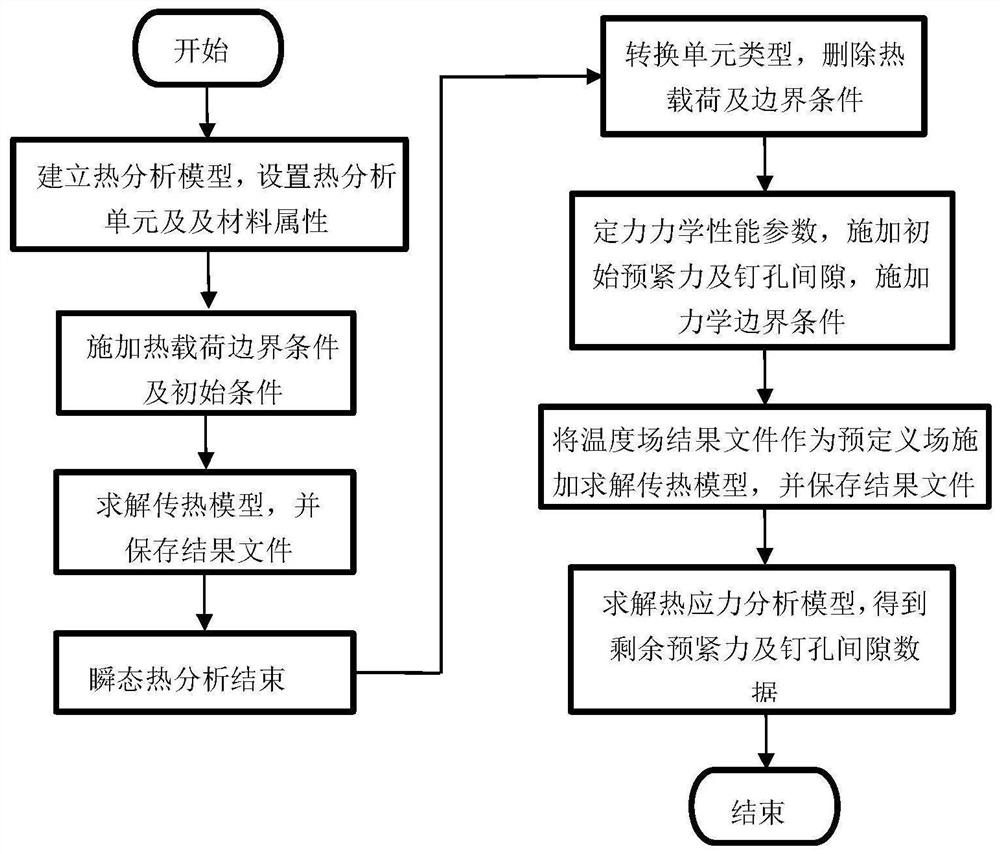

[0021] A method for predicting the evolution of transient high-temperature assembly parameters of a countersunk bolt hybrid connection structure, the prediction method comprising:

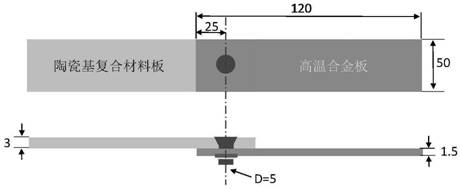

[0022] Step 1. According to the geometric dimensions of the connection structure between the ceramic matrix composite material and the superalloy countersunk head bolt, use ABAQUS finite element software to establish a finite element analysis model. The modeling components include ceramic matrix composite material plate, superalloy plate, superalloy countersunk head screw and Nuts and other components.

[0023] Step 2. Select an eight-node linear heat transfer hexahedron element (DC3D8) and mesh the connection structure.

[0024] Step 3: Assign corresponding thermophysical properties to each component of the established finite element model according to different material properties, including density, specific heat capacity, and thermal conductivity.

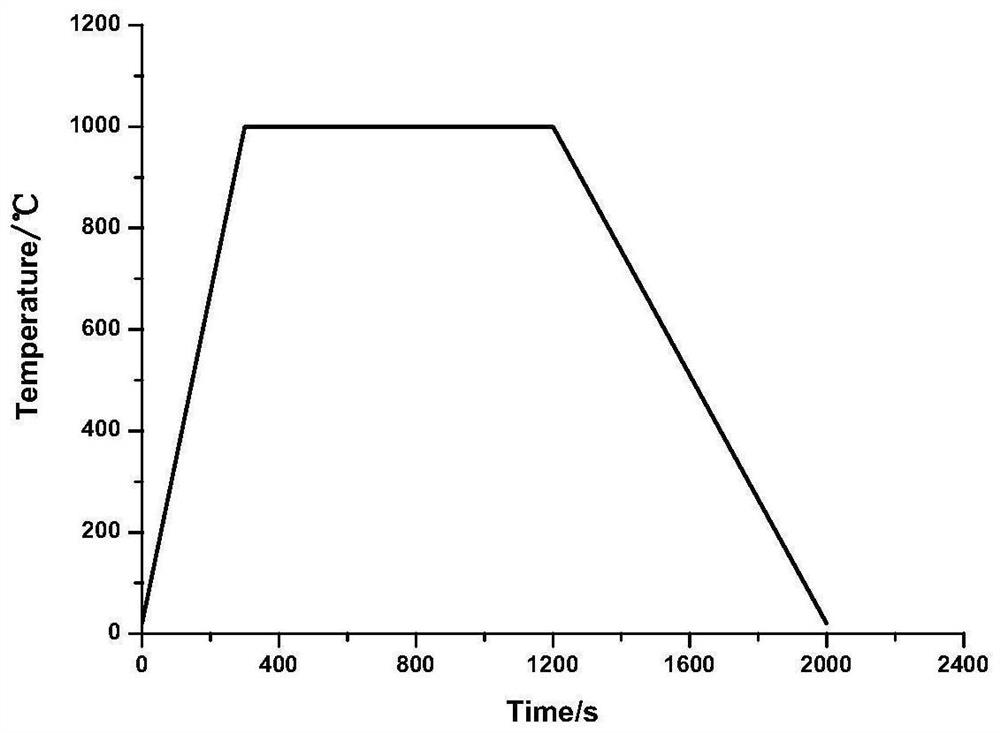

[0025] Step 4. According to the contact rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com