Insulation monitoring device based on non-balanced bridge for direct current system

An insulation monitoring device and unbalanced bridge technology, which is applied in the direction of measuring devices, high resistance measurement, and electrical measurement, can solve problems such as abnormal calculation of system parameters, false alarms, and reductions, so as to reduce impact and ensure safety and reliability. and longevity, the best matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

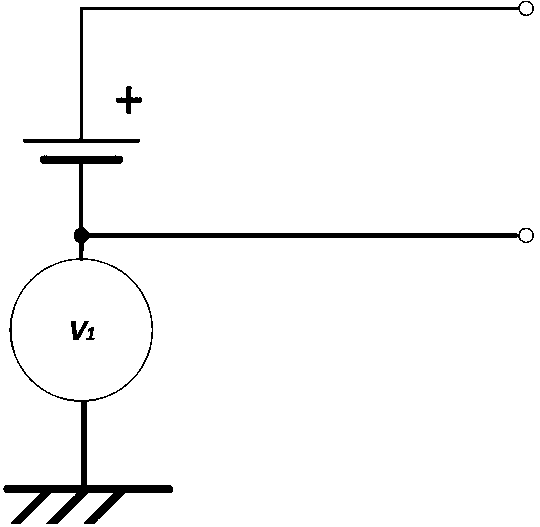

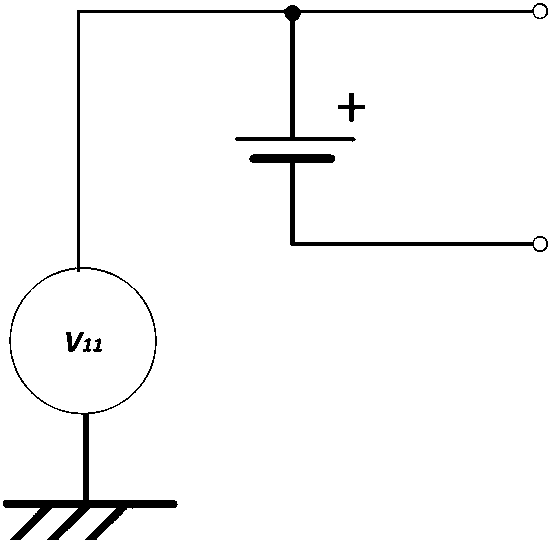

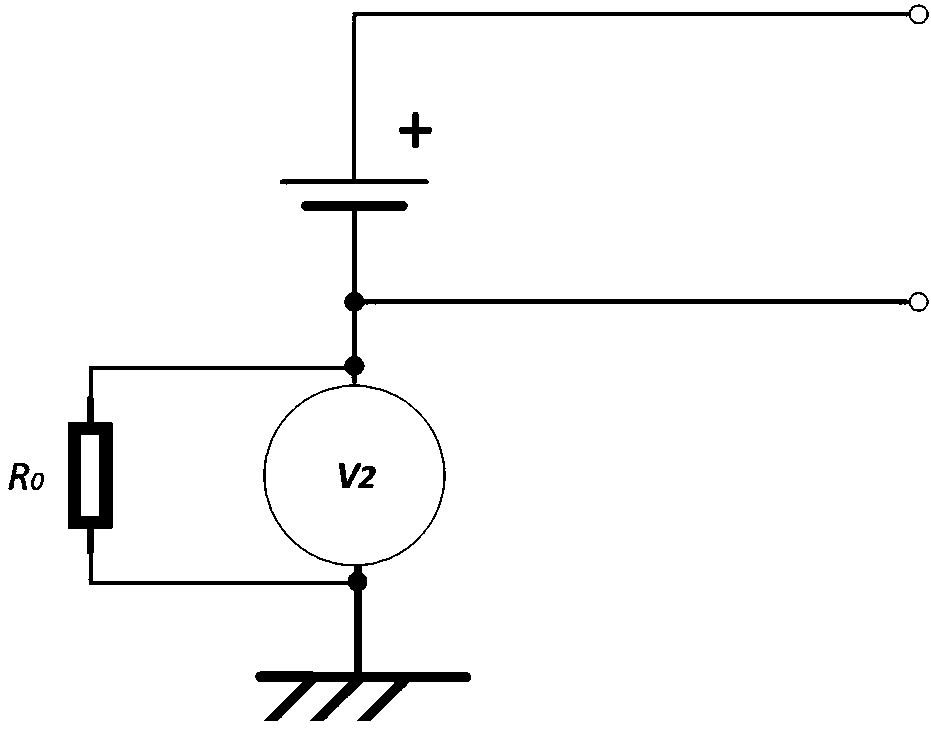

[0035] The detection circuit principle diagram of the present invention is as Figure 5 to Figure 8 shown. Detection circuit such as Figure 5As shown, it includes the first branch connected in series by the first resistor R1, the first switch KG1, the third switch KG3 and the third resistor R3, and the second resistor R2, the second switch KG2, the fourth switch KG4 and the fourth The resistor R4 is connected in series with the second branch in turn. Wherein, the first resistor R1 has the same resistance value as the third resistor R3, and the second resistor R2 has the same resistance value as the fourth resistor R4. The first branch and the second branch are connected in parallel, and the sixth switch KG6 and the seventh switch KG7 are respectively connected to the two ends. Connection points between the first switch KG1 and the third switch KG3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com