Electric power capacitor with prolonged service life

A technology for power capacitors and lifespan, applied in the field of power capacitors, can solve the problems of rising metal shell temperature, failure and scrapping of capacitors, affecting the service life of capacitors, etc., to achieve the effect of prolonging service life, low capacity loss rate, and avoiding the expansion of potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

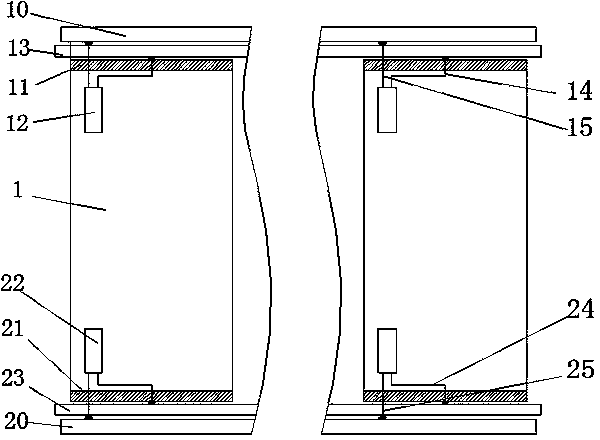

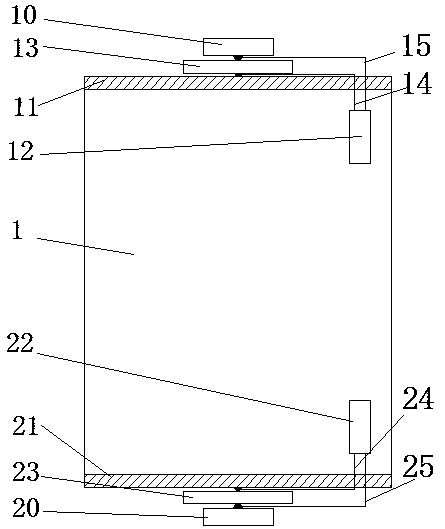

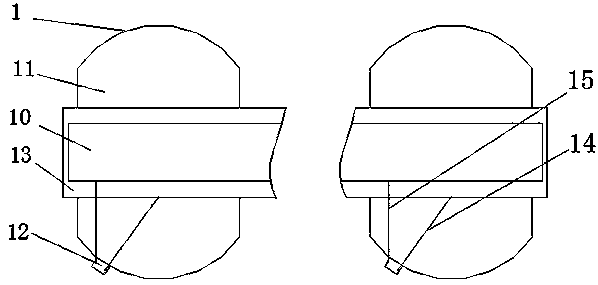

[0027] Such as Figure 1-3 As shown, the power capacitor with extended service life of the present invention includes a casing and multiple groups of single-core groups fixed in the casing.

[0028] The single-core group includes a single core (1), a first electrode copper strip (10), and a copper strip (10) arranged between the first electrode copper strip (10) and the first gold-sprayed layer (11) of the single core (1). A thermal fuse (12), a second electrode copper strip (20), a thermosensitive switch (22) arranged between the second electrode copper strip (20) and the second gold-sprayed layer (21) of the single core (1) And the first insulation pad (13) used for the insulation of the first electrode copper strip (10) and the thermal fuse (12), the second insulation pad (13) used for the insulation of the second electrode copper strip (20) and the thermal switch (22) pad (23); the single-core group includes at least 10 small-capacity single-cores (1), and the capacity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com