Platform and method for greening roof by using waste natural biomass materials as matrix materials

A roof greening and matrix material technology, applied in the fields of greening, environmental protection, and circular economy, can solve the problems of blocked rainwater pipes, excessive scope, inaccurate positioning of patents, etc., and achieve the effect of saving construction costs and costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

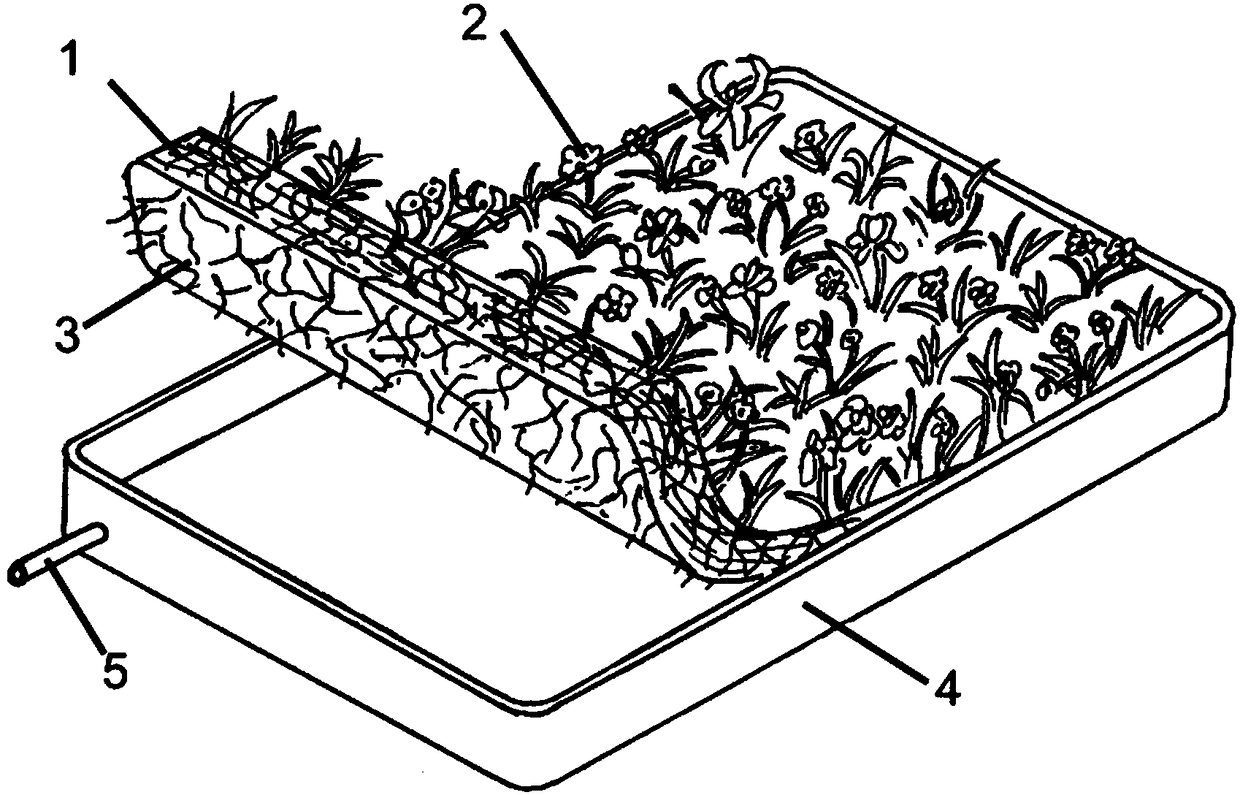

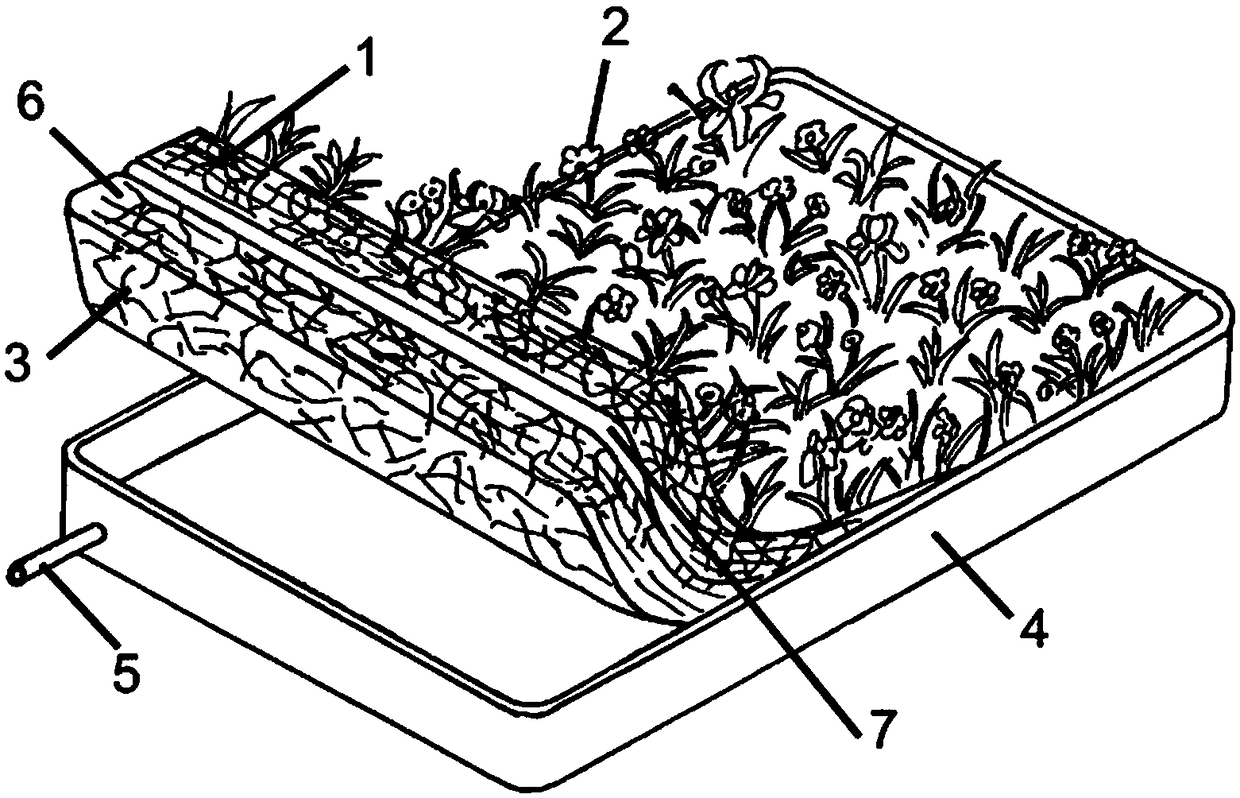

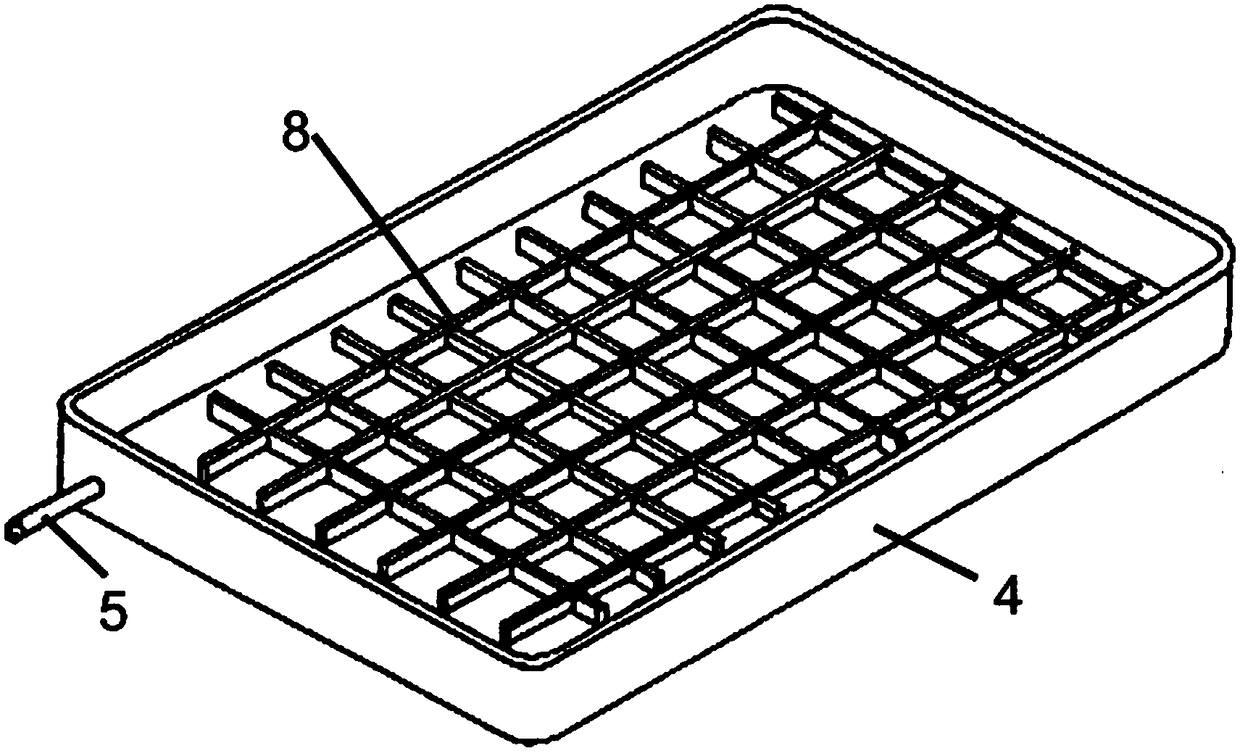

[0063] Attached below Figure 1~6 The examples and examples further illustrate the present invention.

[0064] The bermudagrass lawn can be used for family gardens, public green spaces, parks and other landscape greening. The lawn has attractive colors, well-developed fibrous roots, wide adaptability, strong cold resistance, good heat resistance, tramp resistance, disease resistance, and low pruning resistance. Now take the bermudagrass as an example to introduce its implementation.

[0065] The usual artificial seeding rate of bermudagrass is 10~12g / m 2 ;The sowing rate of spraying planting grass is 15g / m 2 about. Sprinkle a certain amount of grass seeds evenly on the surface of the biomass fiber blanket 1, gently press and knead it to embed it in the gap of the fiber blanket, spray water to make it fully wet, and cure it under suitable temperature and light for 20 days. It can breed stolons and quickly form a plateau.

[0066] The laboratory cultivation is carried out in the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com