Cold pendulum rolling precision forming method for part with thin wall and deep narrow groove

A technology of precision forming and cold rolling, which is applied to other household appliances, household appliances, metal processing equipment, etc., to achieve the effects of low production cost, high material utilization rate, and good organizational and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

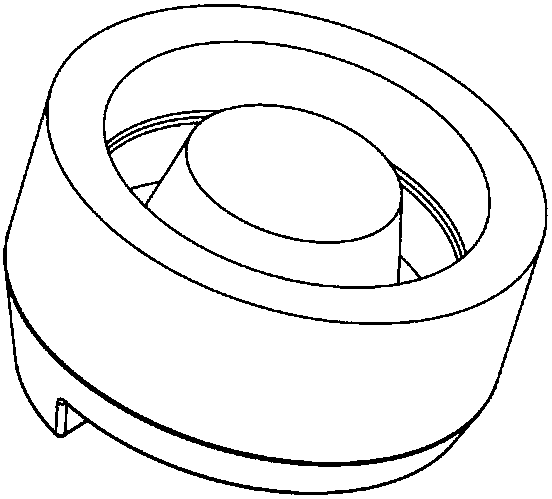

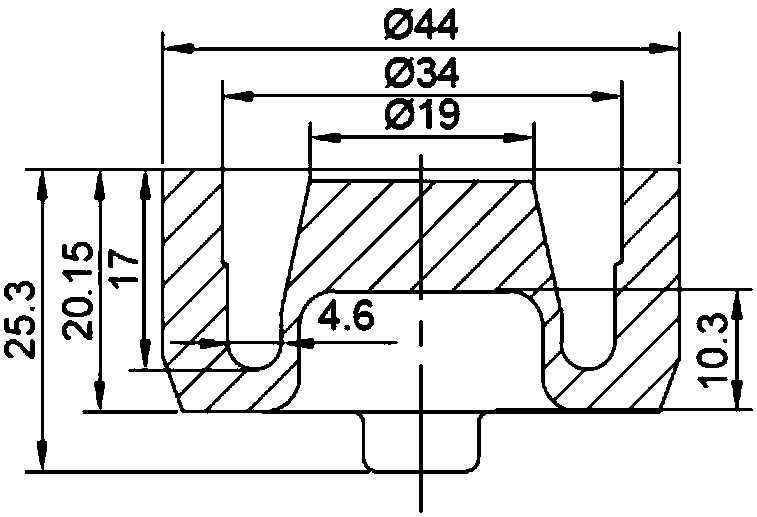

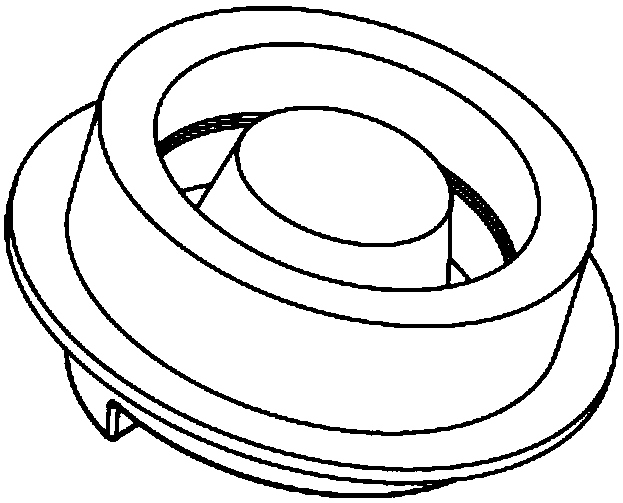

[0027] Such as figure 1 shown, as figure 1 and figure 2 , the finished product of the deep and narrow groove parts processed by the inventive method is 25.3mm high, and the diameter is 44mm, and the deep and narrow groove is wide 4.6mm, and the depth is 17mm.

[0028] Such as figure 1 As shown, the geometric shape of the thin-walled deep narrow groove part is complex, so the composite forming process of hot forging billet-cold swing rolling final forging is adopted. The specific process is: bar blanking-hot forging billet-spheroidizing annealing softening-cold swing Rolling and forging. The forgings are obtained after the final forging by cold swing rolling, and then conventional machining such as deburring is suff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com