Drilling rod machining process

A processing technology and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of large equipment requirements, reduced drill pipe quality, and reduced drill pipe life, so as to achieve simple process operation and easy stress relief , Improve the effect of drill pipe quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

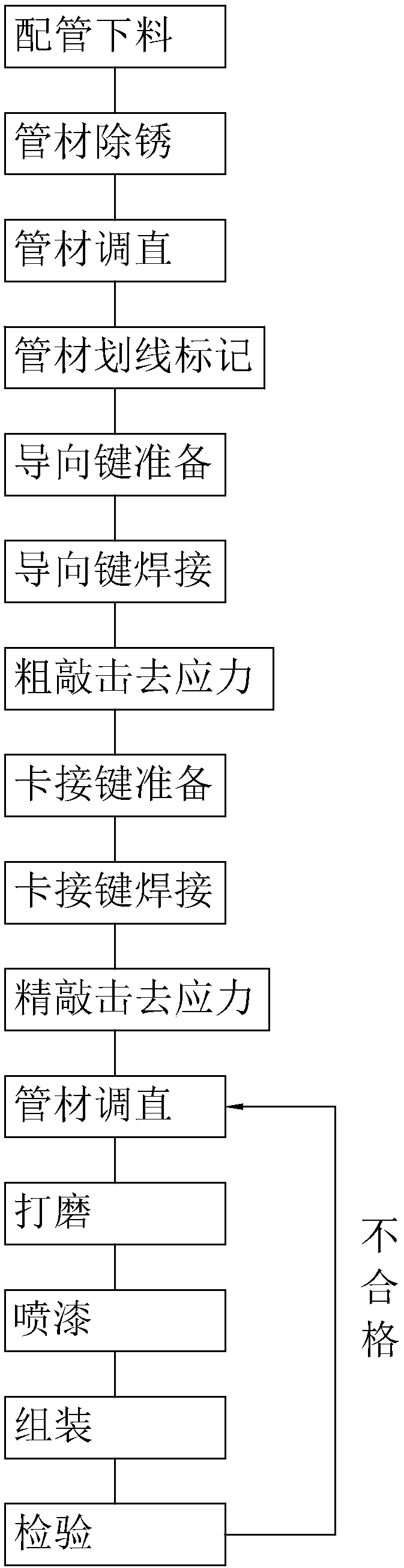

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0050] A drill pipe processing technology, comprising the steps of:

[0051] Step 1: Pipe cutting: Cut the steel pipe with a steel pipe cutting machine to ensure the accuracy of the steel pipe after cutting and reduce the trouble of later repairs.

[0052] Step 2: Pipe rust removal: send the cut steel into the sandblasting derusting machine for all-round derusting, and transport the steel pipe to the sandblasting derusting machine for sandblasting and derusting, so that the long-term storage The rust and dust on the surface of the steel pipe are removed to ensure the cleanliness of the steel pipe surface, which is convenient for later welding processing and improves the welding effect.

[0053] Step 3: Pipe straightening: put the steel pipe on the roller frame for conveying, so as to check whether the steel pipe is beating during the conveying process to ini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com