Rotary type automatic assembling machine for oxygen inhalation and humidification bottle

An automatic assembly machine and rotary technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of defective oxygen-absorbing humidification bottles, labor costs and efficiency are not proportional, and enterprise costs are increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

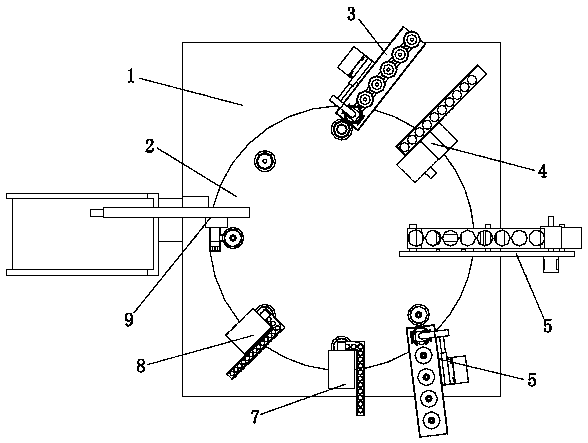

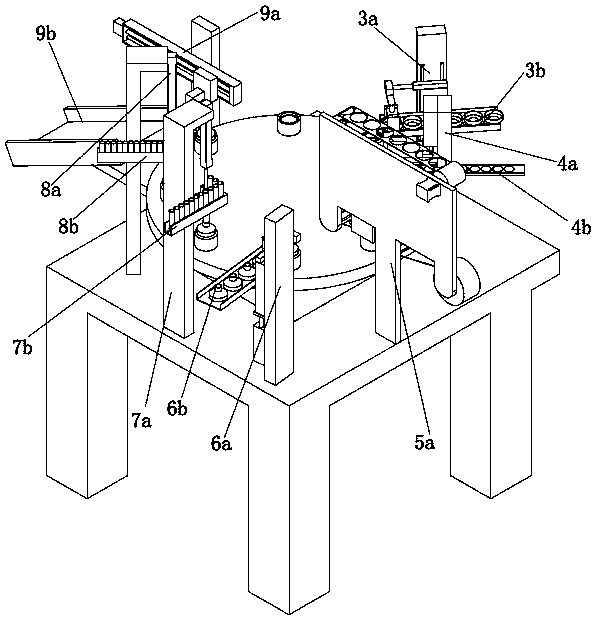

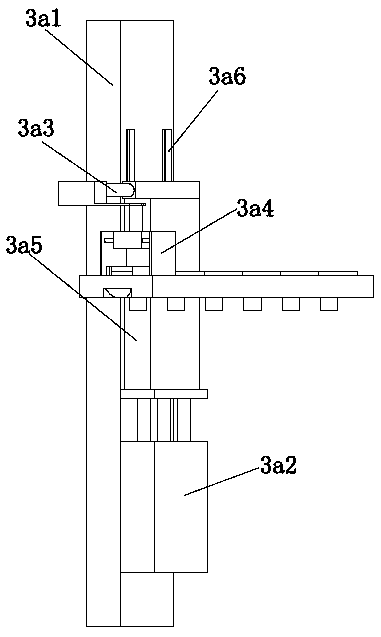

[0035] refer to Figure 1 to Figure 10 A rotary automatic assembly machine for oxygen absorption humidification bottles, including a base 1, a rotary table 2, a lower cover installation station 3, a shunt installation station 4, a humidification body installation station 5, and an upper cover installation station 6. Water guide shell installation station 7, water guide core installation station 8 and unloading station 9, the rotary table 2 includes a rotating motor 2a and a rotating disk 2b, and the rotating motor 2a is fixedly installed on the base 1, The rotating disk 2b is a circular disk-shaped structure, and the rotating disk 2b is installed on the output end of the rotating motor 2a in a horizontal state. The lower cover installation station 3, the splitter installation station 4, the humidification body insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com