Aluminum profile edge grinding and waste material recycling multi-procedure treatment system

A processing system and technology for aluminum profiles, applied in the direction of grinding workpiece supports, machine tools suitable for grinding workpiece edges, grinding machines, etc. and rough sidewalls, etc., to increase the fixing effect, avoid scratching the arm, and increase the grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

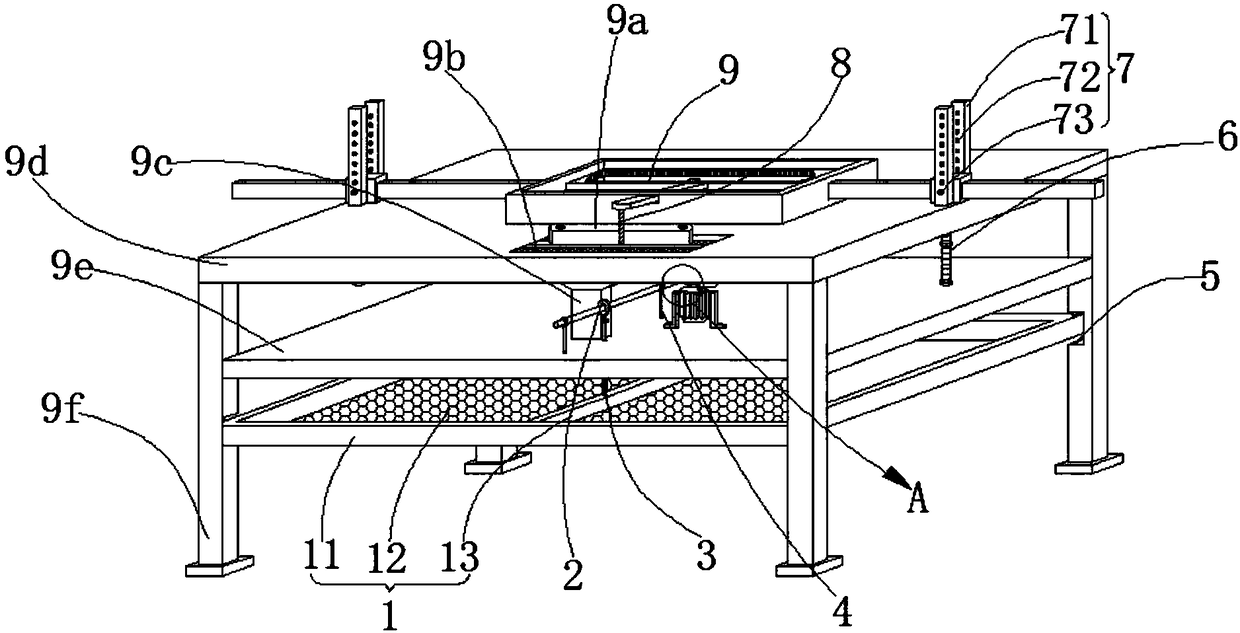

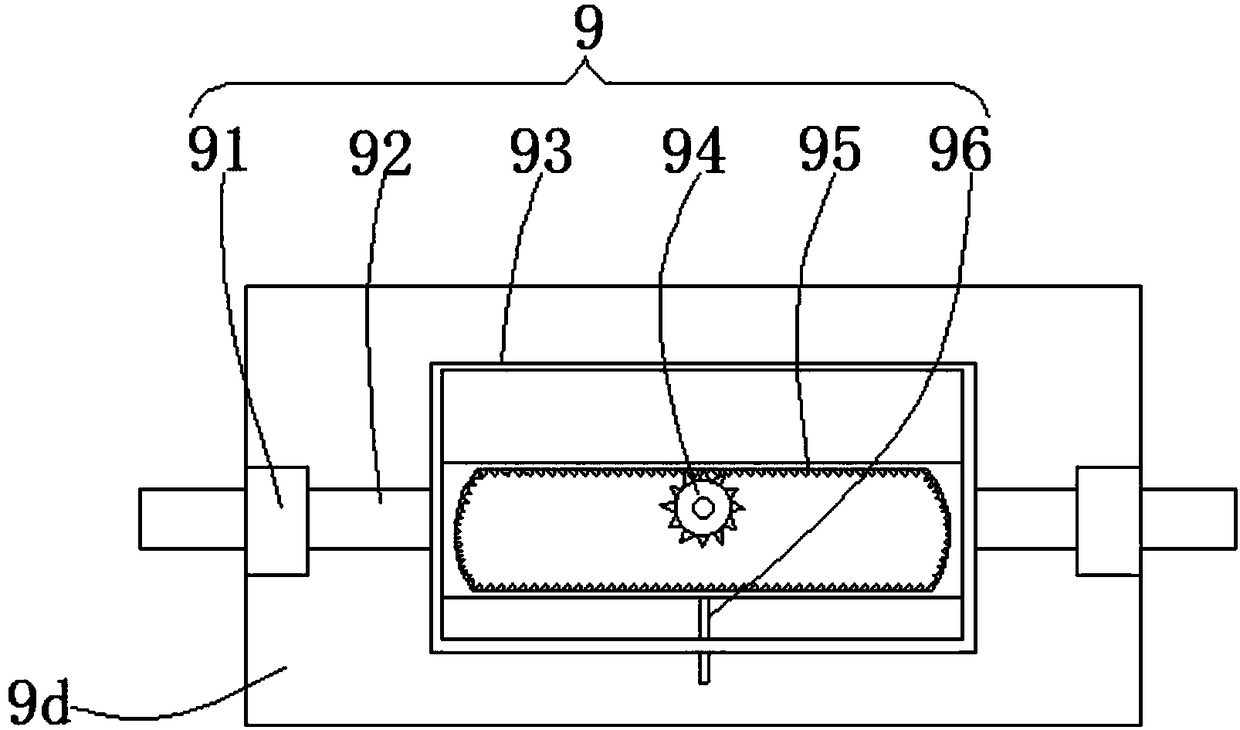

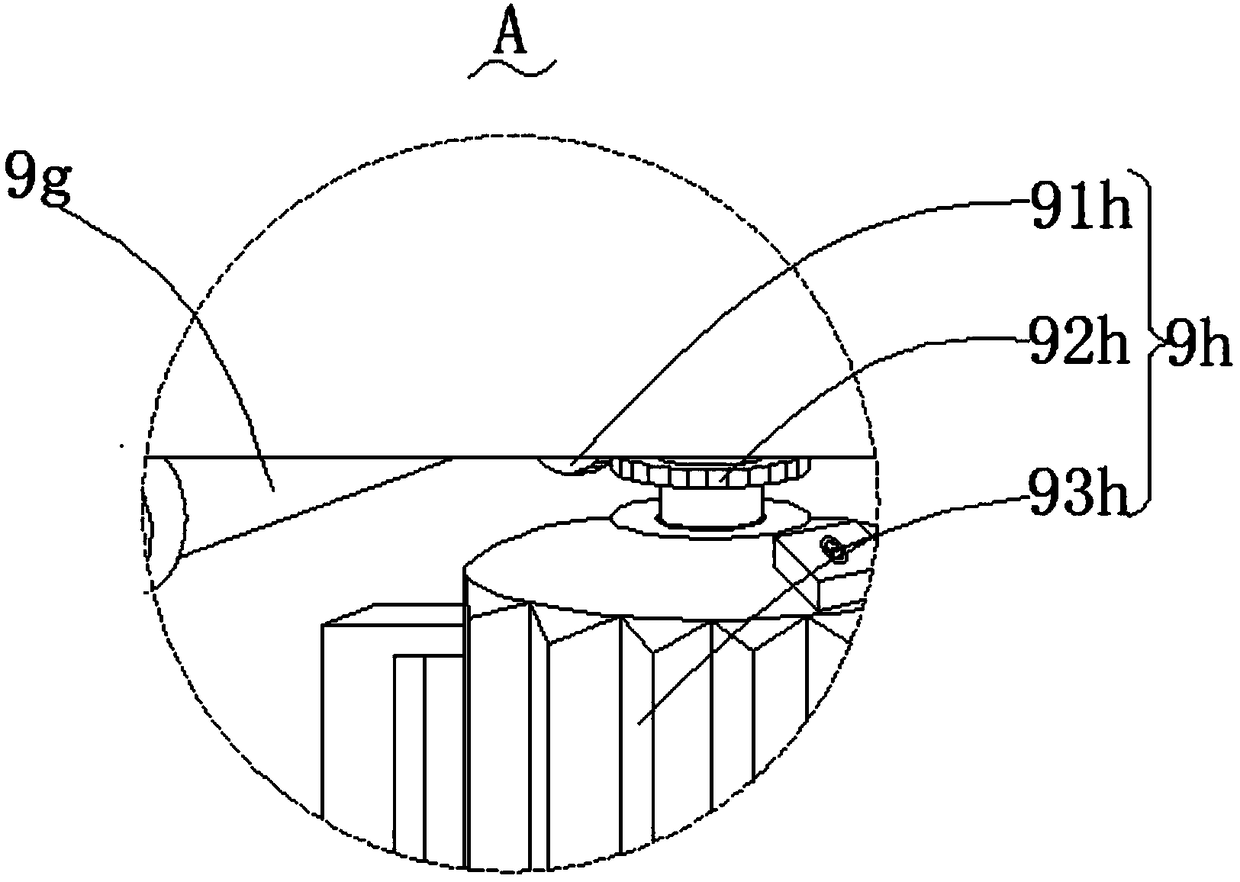

[0032] Such as figure 1 As shown, a multi-process processing system for aluminum profile edging and waste material recovery described in the present invention includes a screening mechanism 1, a protrusion 2, a vibration mechanism 3, a fixed rod 4, a transmission mechanism 5, an adjustment mechanism 6, a fixed Mechanism 7, grinding tool 8, control mechanism 9, place plate 9a, filter screen 9b, funnel 9c, working plate 9d, installation plate 9e, fixed frame 9f, power transmission shaft 9g and driving mechanism 9h; Four described fixed frame 9f The top is fixedly connected to the working plate 9d, and the surface of the working plate 9d is symmetrically fixedly connected to the fixing mechanism 7; the fixing mechanism is slidably connected to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com