Reinforced combined boom

An enhanced and combined technology, applied in the direction of cranes, etc., can solve the problems of waste of surplus, decreased performance of the whole machine, and adjustment of carrying capacity, so as to reduce the cost of use and management, reduce the difficulty of tooling and production, and the difficulty of blanking and processing Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0040] The invention is a reinforced combined jib, which breaks the design thinking of the previous jib system, and changes the welded integral jib into an assembled combined jib, so that the jib system is no longer limited by the transportation size and weight. And according to the actual hoisting requirements and hoisting conditions, a general-purpose jib and a reinforced jib can be combined. The jib sections used by the general-purpose jib and the reinforced jib are the same jib section, and the utilization rate of the jib section is high.

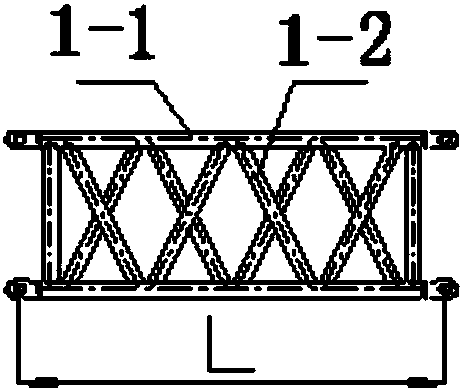

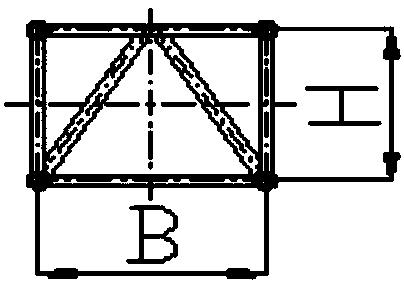

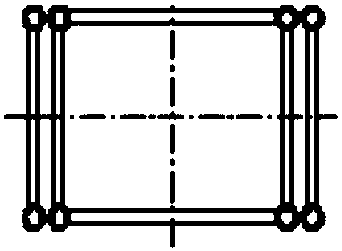

[0041] Figure 3a , Figure 3b , Figure 3c It is a schematic diagram of the single-arm section structure of the present invention, each single-arm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com