A construction method for the foundation of a large-scale arch bridge with permeable geology

A construction method and water permeability technology are applied in the construction field of the foundation of large arch bridges with water permeability, which can solve the problems of insufficient water-stop curtain protection, waste of concrete raw materials, slow construction speed, etc., so as to prevent cofferdam landslides and collapse, reduce Engineering super-square problem and the effect of improving ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A construction method for a large-scale arch bridge foundation with permeable geology, characterized in that:

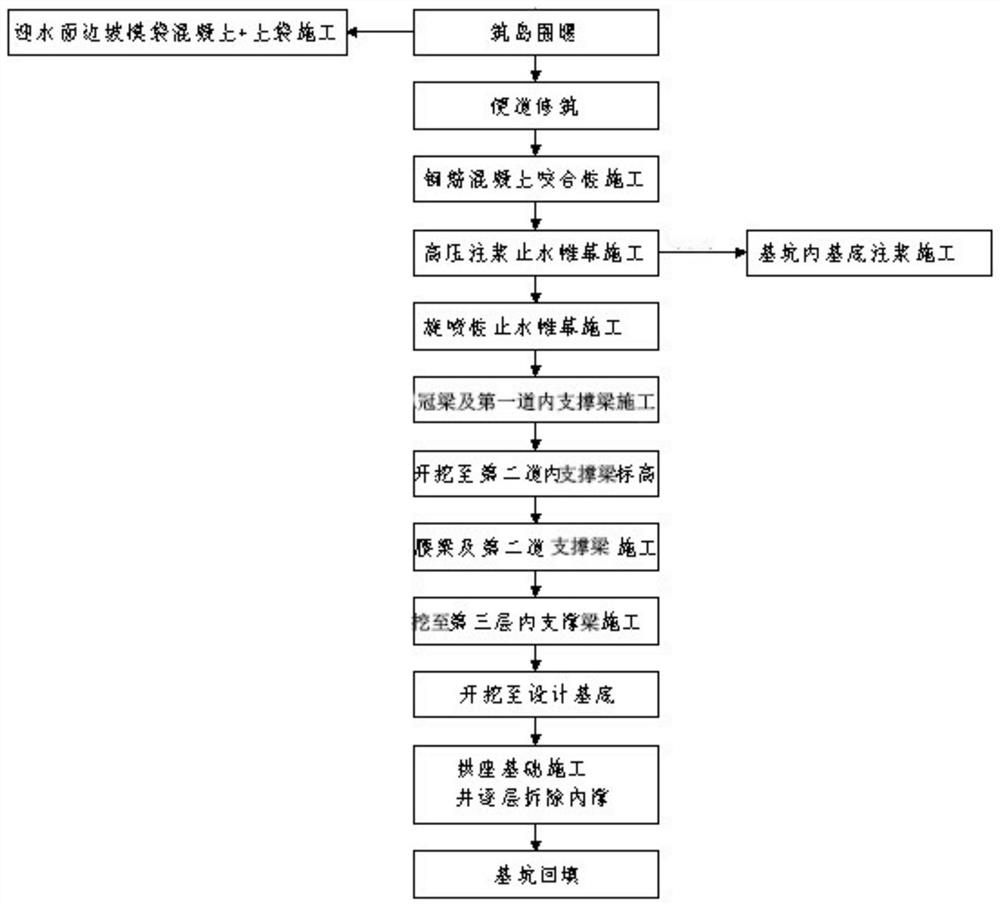

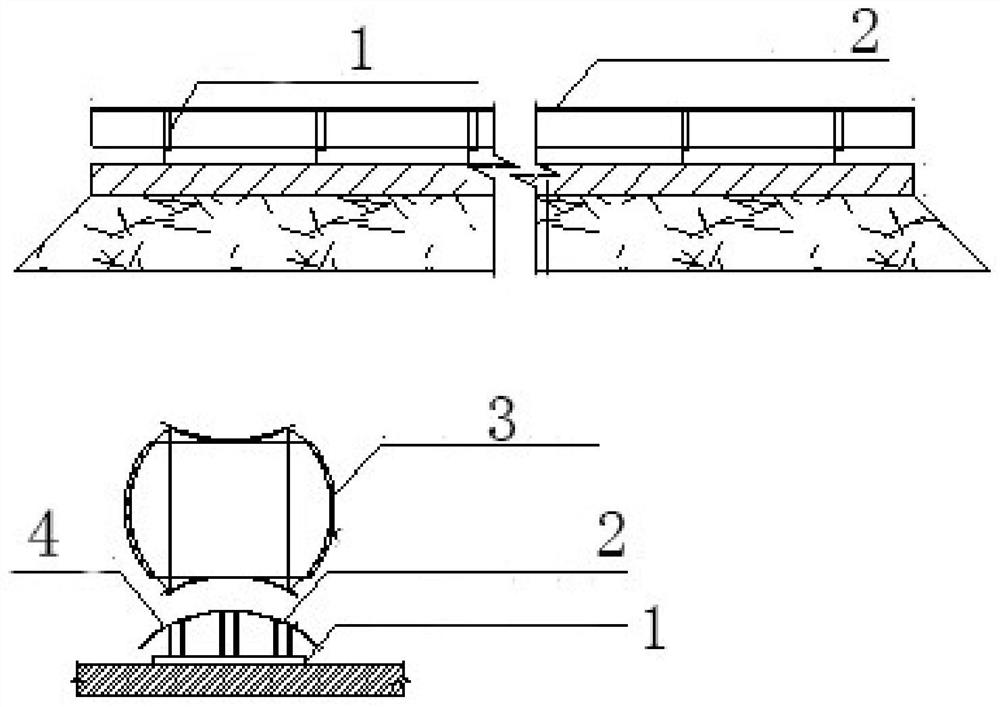

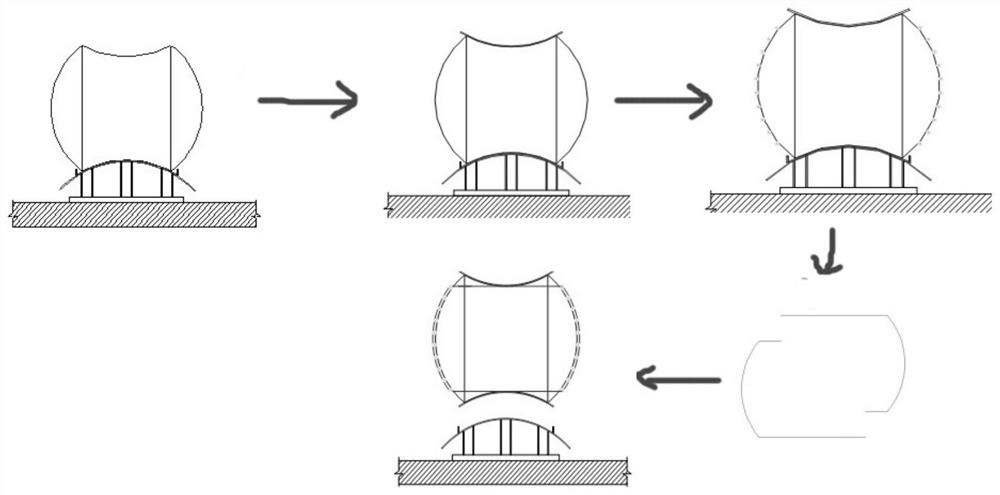

[0071] It includes the following steps: building island cofferdam → construction of access road → construction of reinforced concrete occlusal pile → construction of high-pressure grouting water-stop curtain → construction of water-stop curtain of rotary grouting pile → construction of crown beam and first inner support beam → excavation to the second Elevation of supporting beams in the road → construction of waist beams and supporting beams in the second road → excavation to the elevation of supporting beams in the third road and construction of supporting beams in the third road → excavation to the design base → construction of abutment foundation and removal of inner supports layer by layer → foundation pit backfill;

[0072] The specific implementation is as follows:

[0073] Tsukishima cofferdam

[0074] 1. Island construction

[0075] In the construc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com