Mountain-cutting heavy punch

A technology of heavy hammer and hammer body, which is applied in the manufacture of crushing equipment for construction machinery, mines, and tunnels. It can solve the problems of small weight of the hammer body of the crusher, easy damage of the drill rod head, and limited strength, so as to achieve no exhaust gas emission and save energy. The cost and the effect of a large blow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

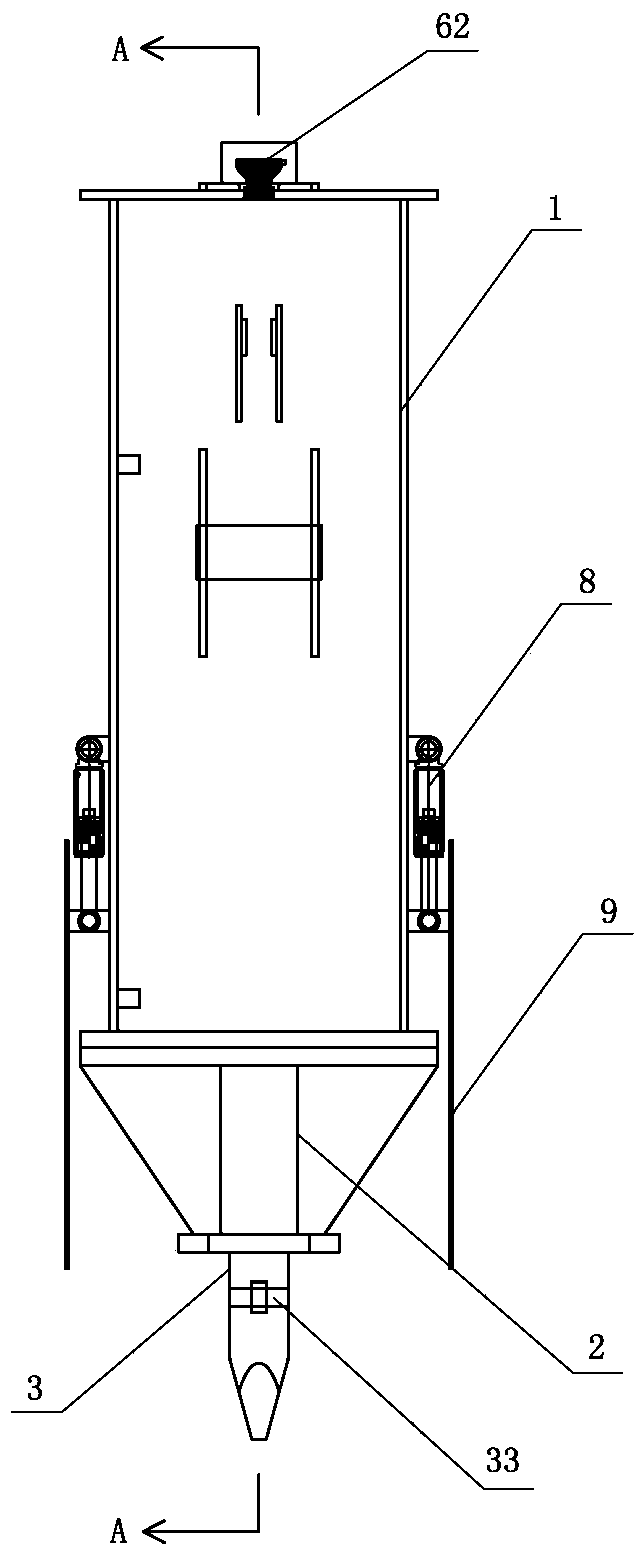

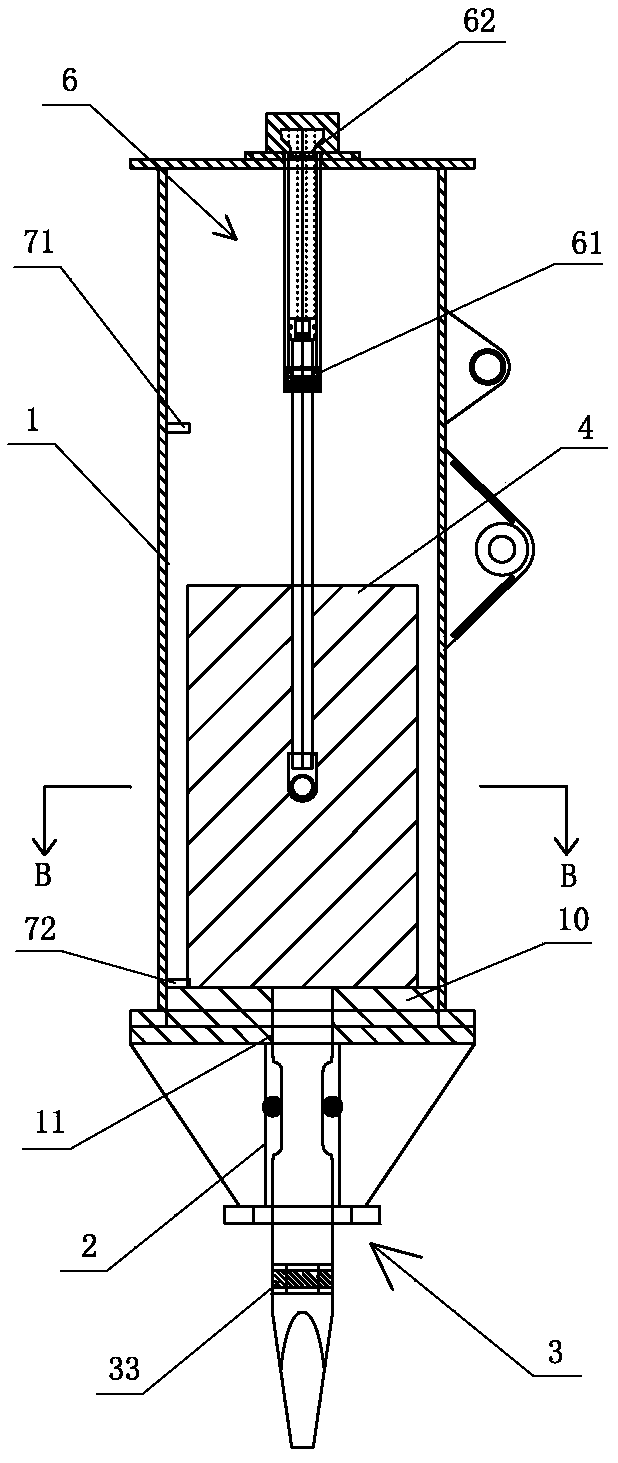

[0027] Such as figure 1 , 2 , 3, 4, and 5, a mountain-opening heavy hammer includes a square barrel body 1, a through hole 11 is opened on the bottom wall of the barrel body 1, and a guide sleeve 2 is set in the through hole 11, and the inner sleeve of the guide sleeve 2 A drill rod 3 is provided, and the drill rod 3 can move up and down in the guide sleeve 2;

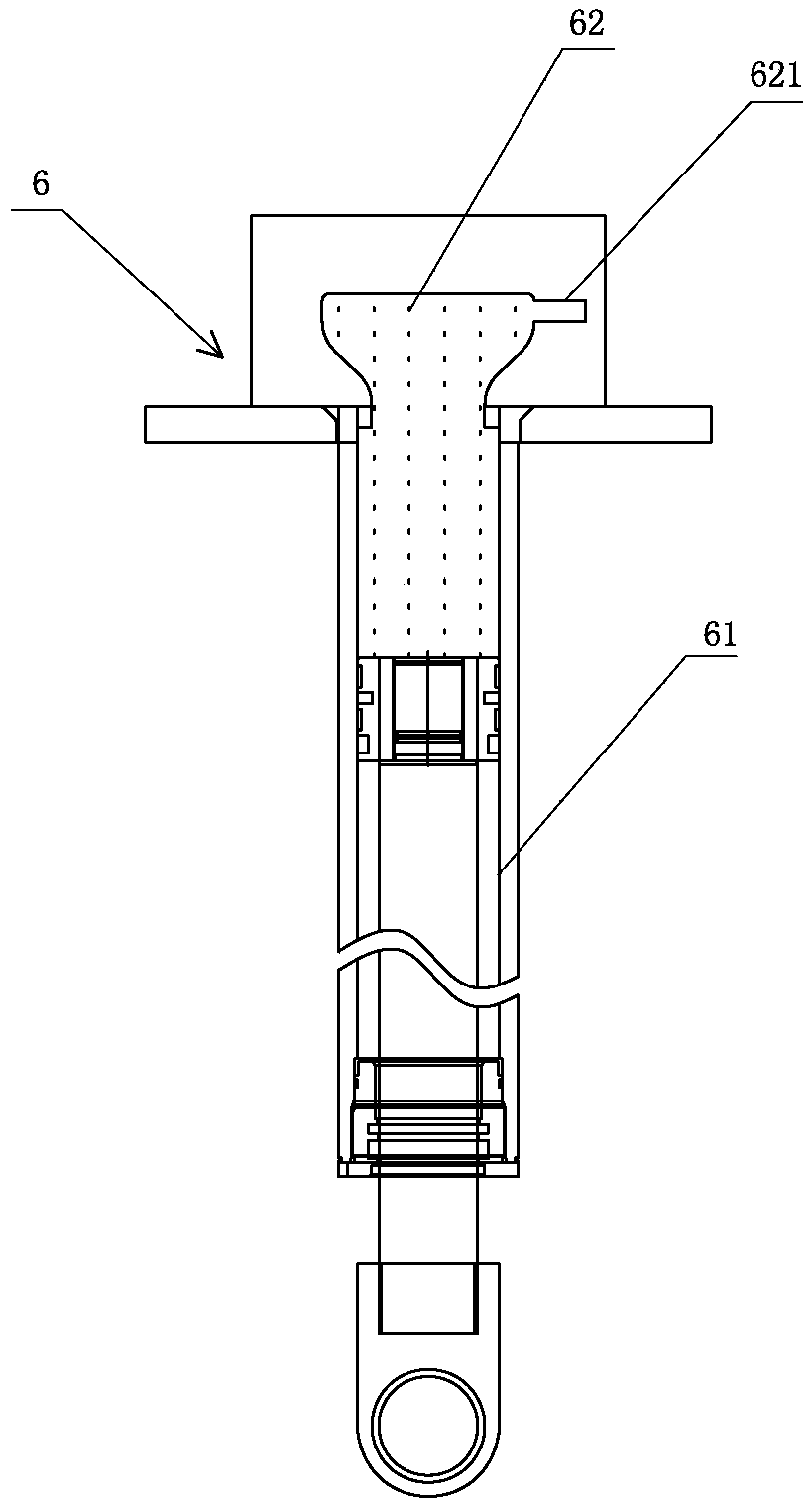

[0028] A circular hammer body 4 and a slideway 5 are arranged in the staving body 1, and the slideway 5 is arranged on the inwall of the staving body 1. Under the action of pulling, it can rise along the slideway 5, and the hammer body 4 can descend along the slideway 5 under the push and gravity of the lifting and pushing device 6; the lifting and pushing device 6 includes a first oil cylinder 61, a nitrogen chamber 62, and a nitrogen chamber 62 is provided with an air nozzle 621; the cylinder barrel of the first oil cylinder 61 communicates with the nitrogen chamber 62, and the piston rod of the first oil cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com