Initiation state inspection method of exploder for simulating high G value test of centrifuge

An inspection method and centrifuge technology, applied in the direction of measuring devices, material inspection products, blasting, etc., can solve the problem of large-scale dams, expensive costs and large-scale test expenses, and it is difficult to truly reveal the mechanical behavior and destruction process of the explosion prototype and other problems to achieve the effect of low cost and overcoming the problem of blast rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

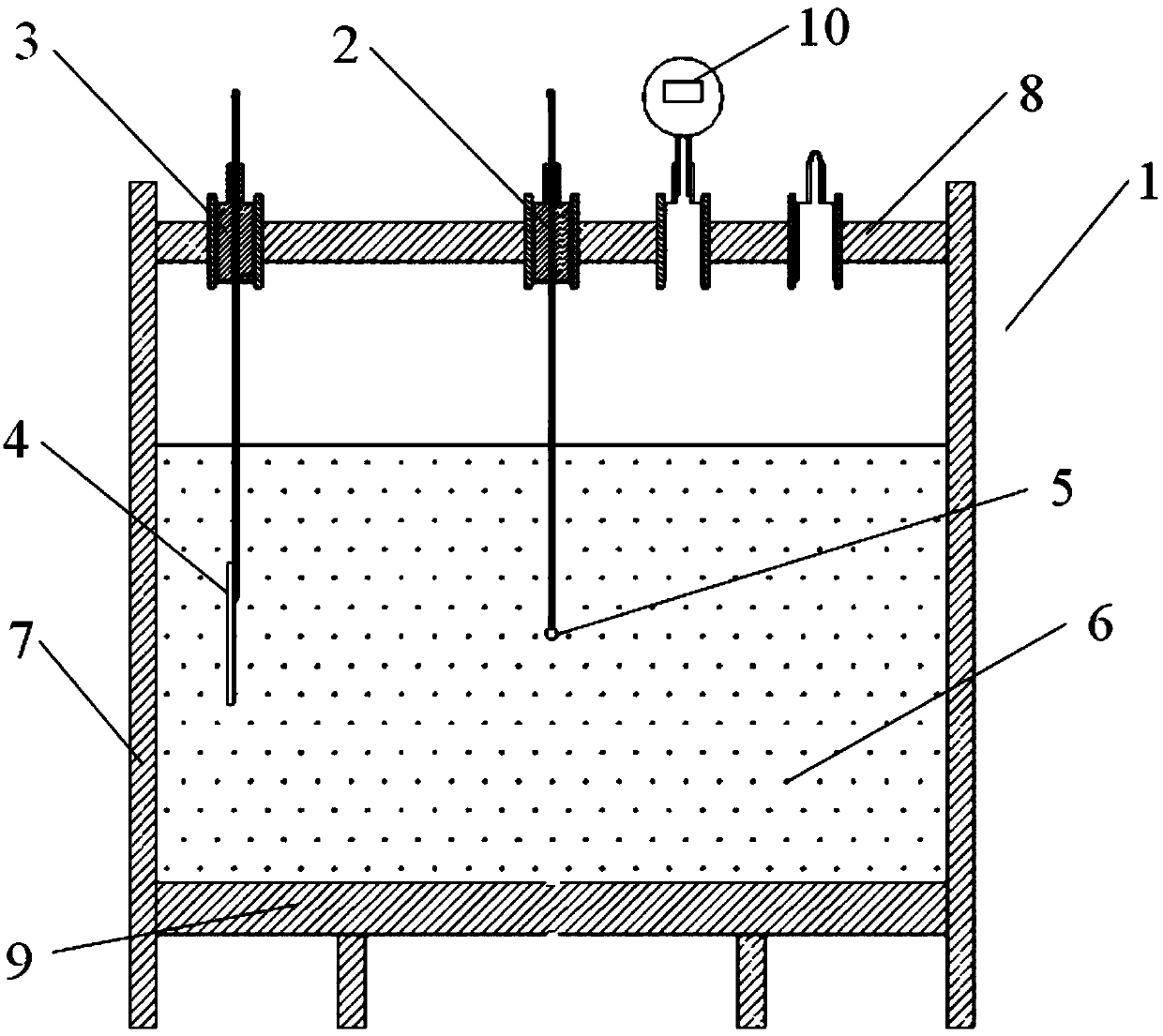

[0049] 1. Explosive devices and related measuring equipment

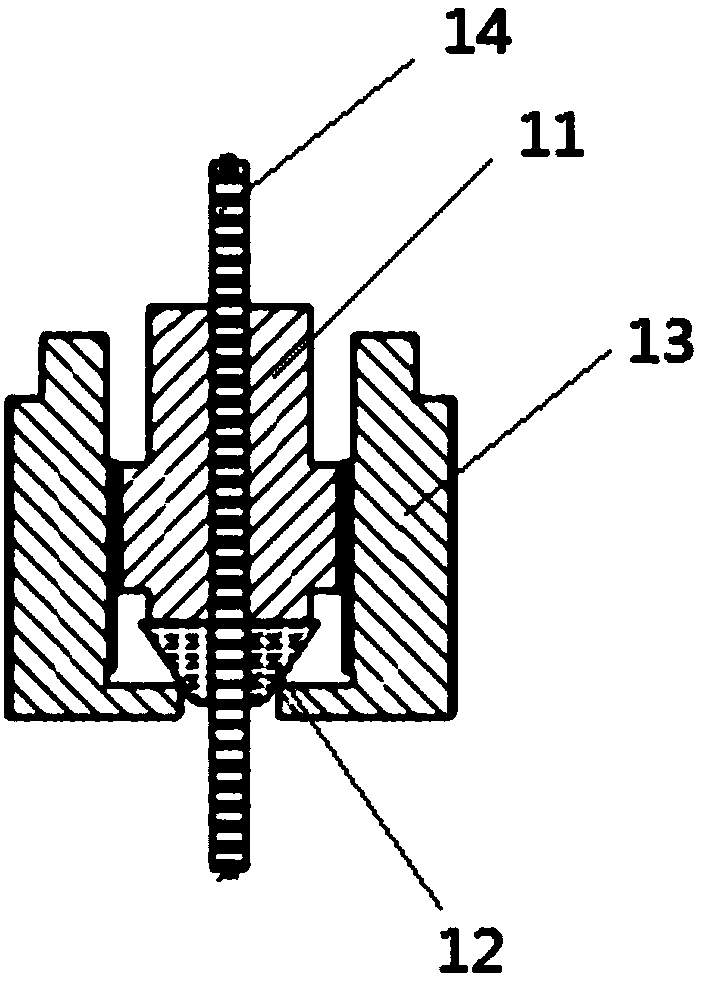

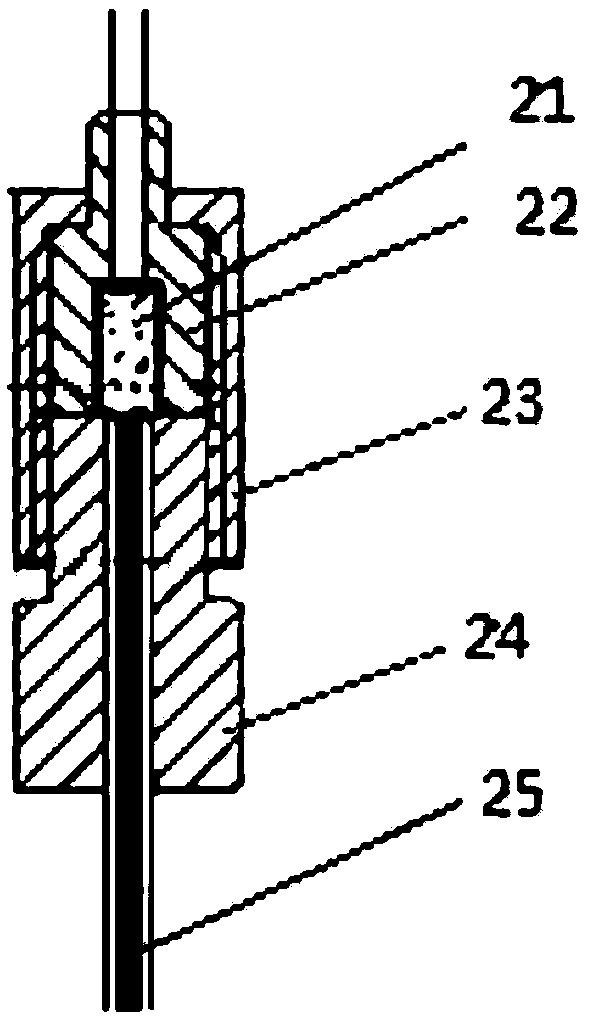

[0050] Such as figure 1 As shown, the underwater pressure explosion test device of the present invention comprises an explosion sealed container 1, an explosion assembly and a sensor 4, and the container 1 includes an upper cover plate 8, a base 9 and an outer wall 7, and the upper cover plate 8 is provided with a central through hole, a sensor through Hole and air pressure valve, explosion assembly and sensor 4 pass through the center through hole and sensor through hole respectively and are arranged in the container cavity; Sensor and charge are arranged at the same level, and explosion assembly and sensor 4 are sealed and fixedly connected by sealing joint 2 On the upper cover plate 8 of the container 1; the lower half of the container is filled with water, and the upper half is filled with high-pressure gas.

[0051] The charge and the sensor are arranged into the interior of the container from the two through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com