Calculation method for shape changes of cross gates of gating systems for casting

A technology of pouring system and calculation method, which is applied in the direction of calculation, casting molding equipment, casting mold, etc., can solve the problems of increasing production cost and reducing output, and achieve the effect of reducing output, reducing the number of cavities, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

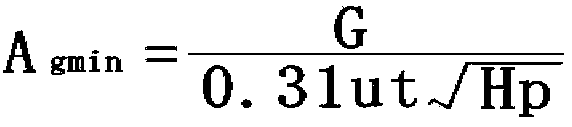

[0016] The present invention provides a calculation method for the shape change of the runner of the gating system for casting, which uses the volume method to establish a relational expression and calculate the shape change of the runner. Since the pouring process of castings is a process of filling with liquid metal, it is a matter of controlling a certain flow rate within a certain period of time. The spoiler is used to control the flow, so that the slag in the front runner has enough time to float up. So, it's about volume, not shape. It can be seen that VH=∑Aru×LH formula (1)

[0017] In formula (1): VH is the runner volume; ∑Aru is the cross-sectional area of the runner; LH is the length of the runner.

[0018] If it is necessary to change the shape of the runner of the casting gating system, generally the length of the runner has changed. In the process of this shape change, if the shape of the runner is to be calculated, the conditions that need to be met are: runn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com