Image sensor and forming method thereof

An image sensor and patterning technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of less light absorption, difficulty in generating photoelectrons, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the prior art, infrared image sensors have been widely used in monitoring, automobile, medical and other fields, however, the existing infrared image sensors have low sensitivity.

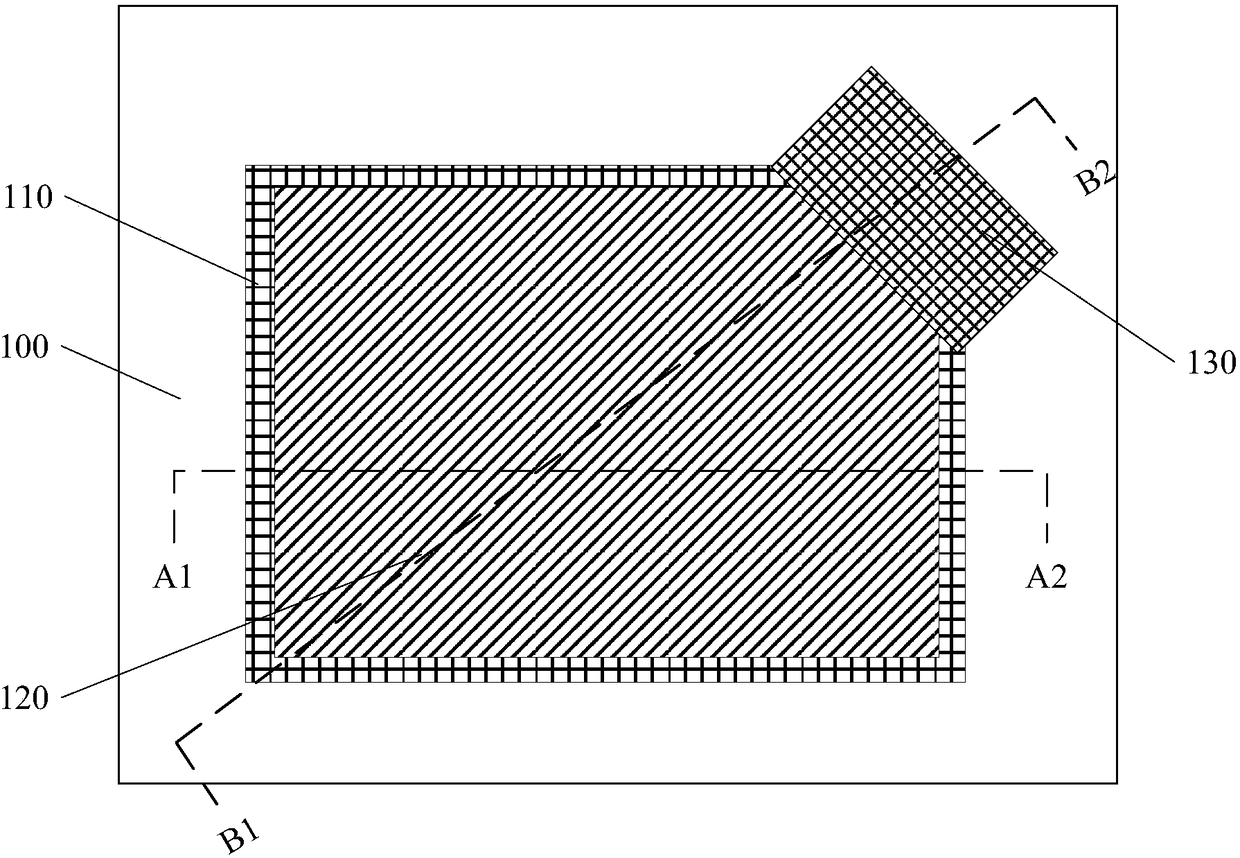

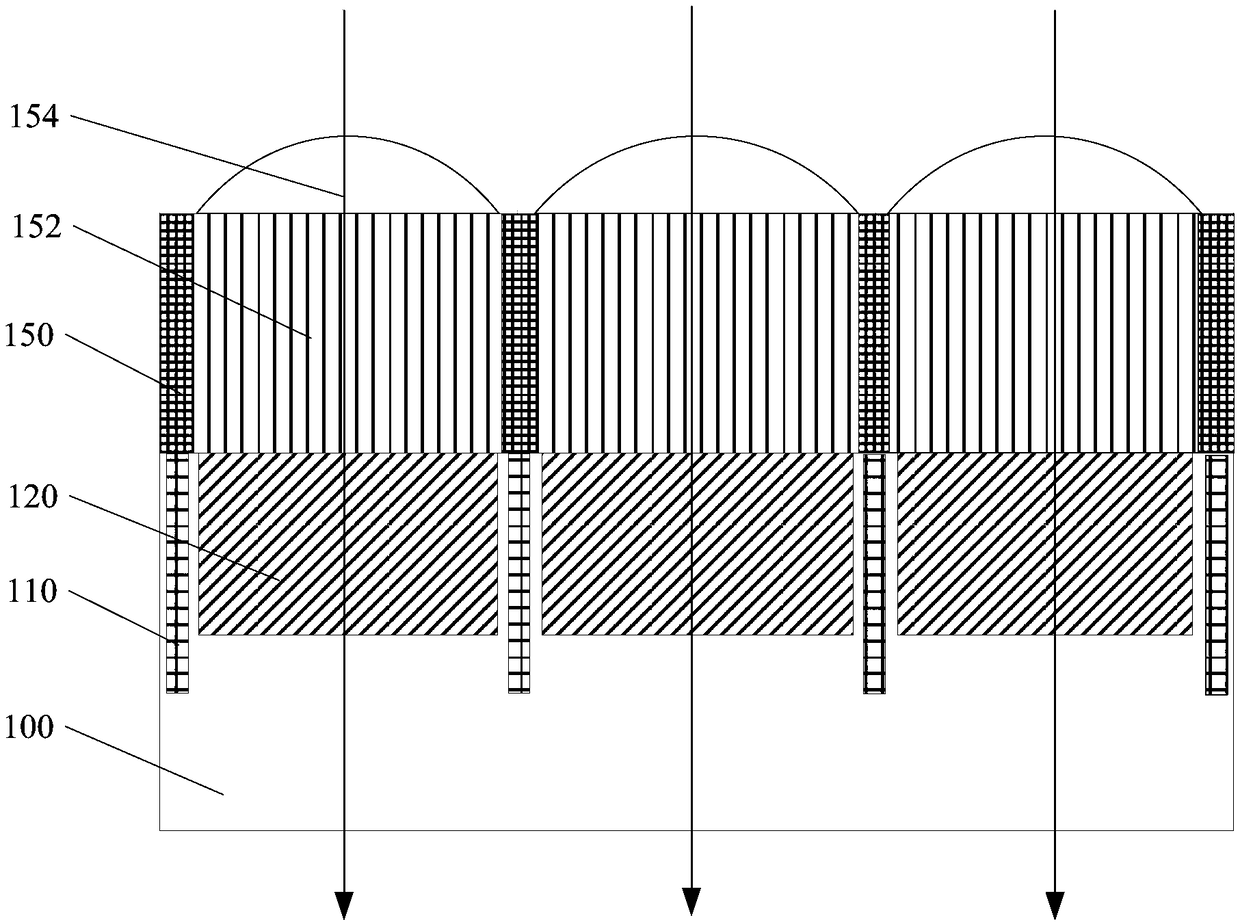

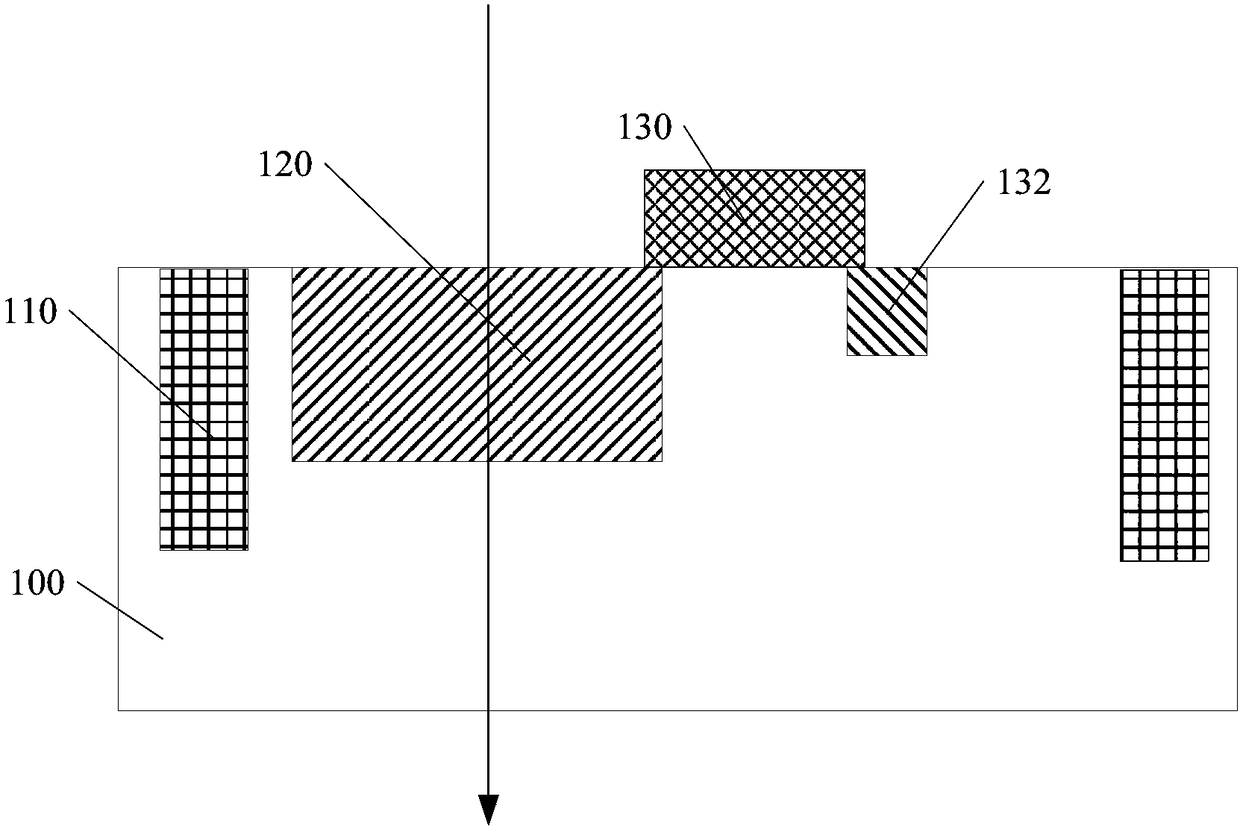

[0027] combined reference Figure 1 to Figure 3 , figure 1 is a top view of an image sensor in the prior art, figure 2 Yes figure 1 Schematic diagram of the cross-sectional structure along the cutting line A1-A2, image 3 Yes figure 1 Schematic diagram of the cross-sectional structure along the cutting line B1-B2.

[0028] The image sensor may include a semiconductor substrate 100 , an isolation structure 110 , a photodiode doped region 120 , a transfer gate 130 and a floating diffusion region 132 .

[0029] Wherein, the isolation structure 110 is located in the semiconductor substrate 100 for isolating adjacent photodiode doped regions 120 .

[0030] The photodiode doped region 120 is located in the semiconductor substrate 100 .

[0031] The transfer gate (Transfer Gate, TG) 130 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com