Ku-frequency-band miniaturized polarization rotating mechanism assembly

A technology of polarization rotation and frequency band, applied in the field of vehicle antenna, airborne antenna, and shipborne antenna, it can solve the problems of complex winding of power supply and signal cable of low noise amplifier, complex structure of feed network, and poor performance reliability. , to achieve the effects of stable electrical performance reliability, high gain, and low cross-polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

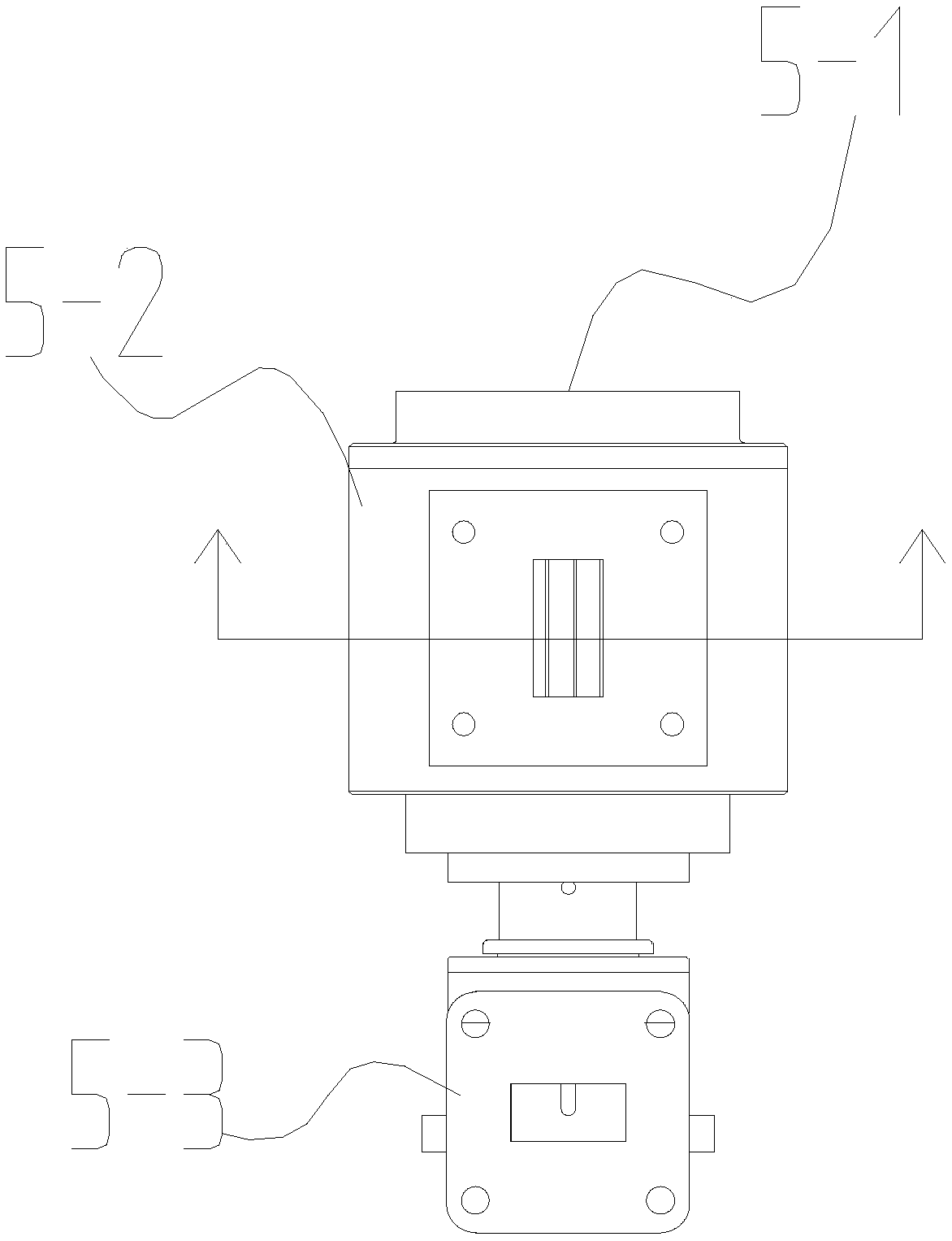

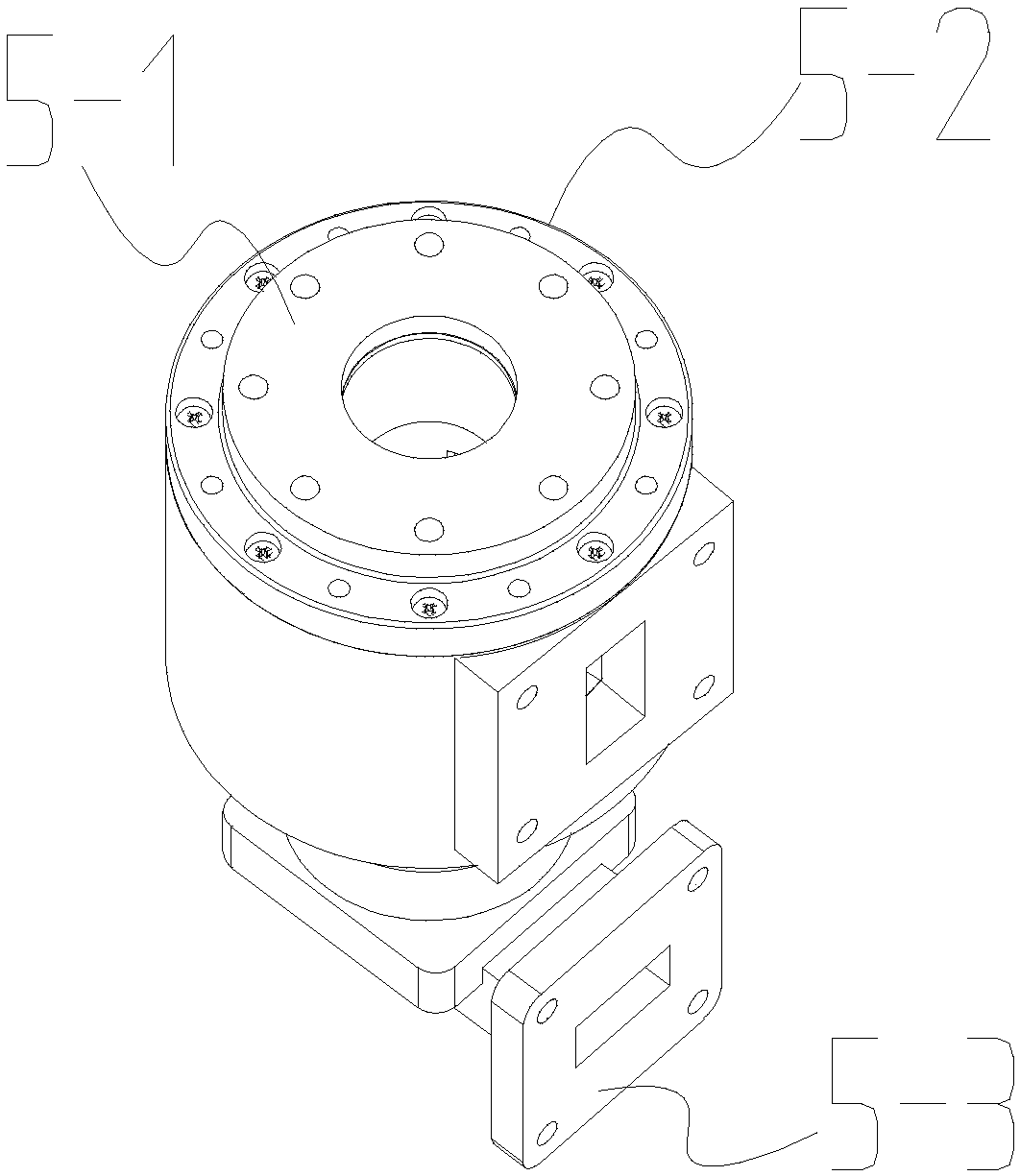

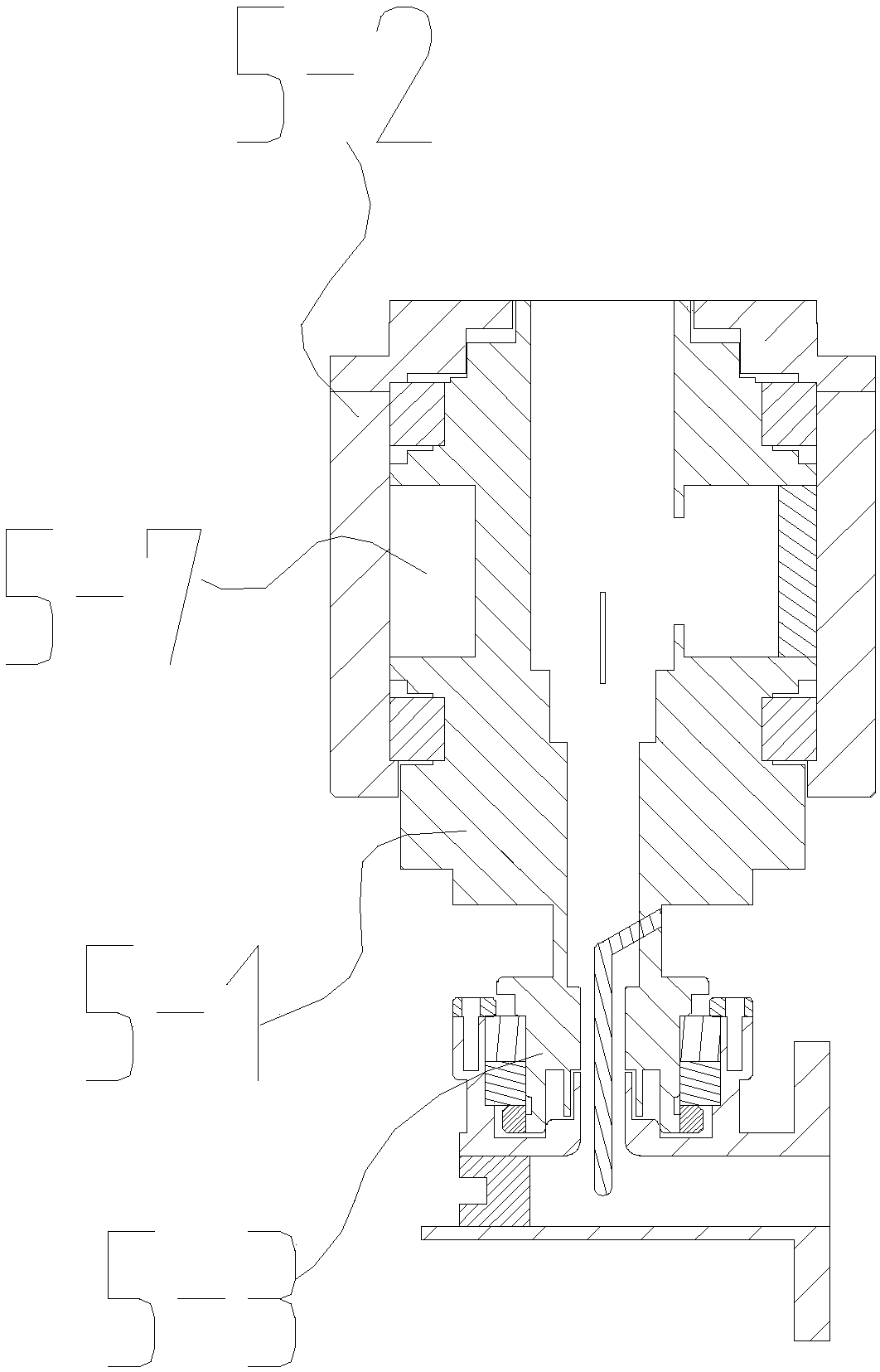

[0026] Example 1, such as Figure 1-4 As shown, a Ku-band miniaturized polarization rotating mechanism assembly is provided, which includes a rotating mechanism for adjusting signal polarization matching and a rotating joint 5-3 for transmitting signals. The rotating mechanism includes a center as a rotor. The waveguide 5-1 and the fixed cylinder 5-2 as the stator, the central waveguide is movably fitted in the inner cavity of the fixed cylinder;

[0027] The outer wall of the central waveguide is provided with a waveguide slot body, one end of the waveguide slot body is provided with a rotor matching block, and the stator matching block is located at the other end of the waveguide slot body. The fixed cylinder is wrapped around the central waveguide to close the top surface of the waveguide slot body. The rotor matching block is fixedly connected to the side wall of the central waveguide, the stator matching block is fixed to the inner wall of the fixed cylinder, and the rotor m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com