Efficiency optimization control method for switched reluctance motor system

A switched reluctance motor and optimized control technology, which is applied to control the direction of the generator through the change of the magnetic field, can solve the problems of differences, inability to obtain high control accuracy, and complex operating conditions of the motor, and achieve good results and good engineering application value , the effect of wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the example of the present invention will be further described:

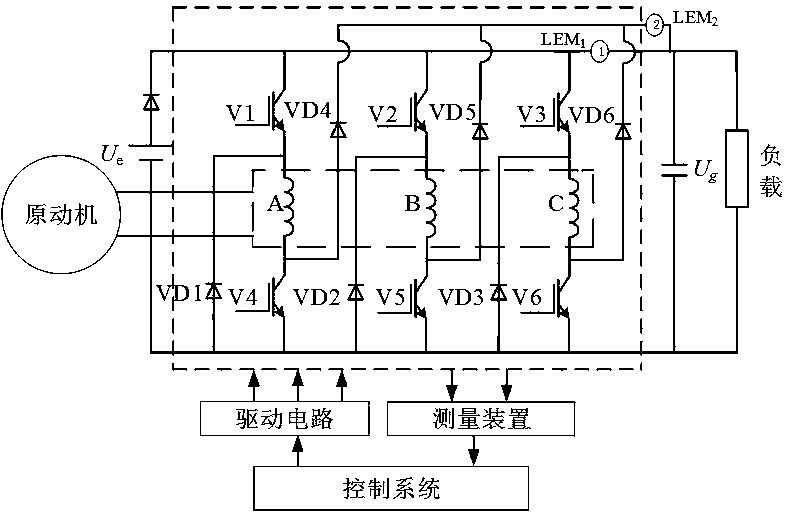

[0014] The switched reluctance motor system is mainly composed of five parts: prime mover, switched reluctance motor, power converter (including excitation power supply), control system and load, such as figure 1 shown. In this system, the switched reluctance motor, as the core component of electromechanical energy conversion, converts the input mechanical energy into electrical energy under the drag of the prime mover. The power converter is used as a channel for energy conversion. In the excitation phase, the external DC power supplies power to the phase winding through the power converter; in the freewheeling phase, the phase winding feeds back energy through the power converter. As the central part, the control system samples the given quantity (given power, given excitation voltage, etc.) and physical quantity (rotor position signal, phase voltage, pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com