Variable shaft height wheel

A technology of axle height and wheels, which is applied in the direction of wheels, axle combinations, vehicle components, etc., can solve the problems of complex power transmission path, affecting the ability of vehicles to pass obstacles, and complex road conditions, so as to improve obstacle avoidance ability, easy active control, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

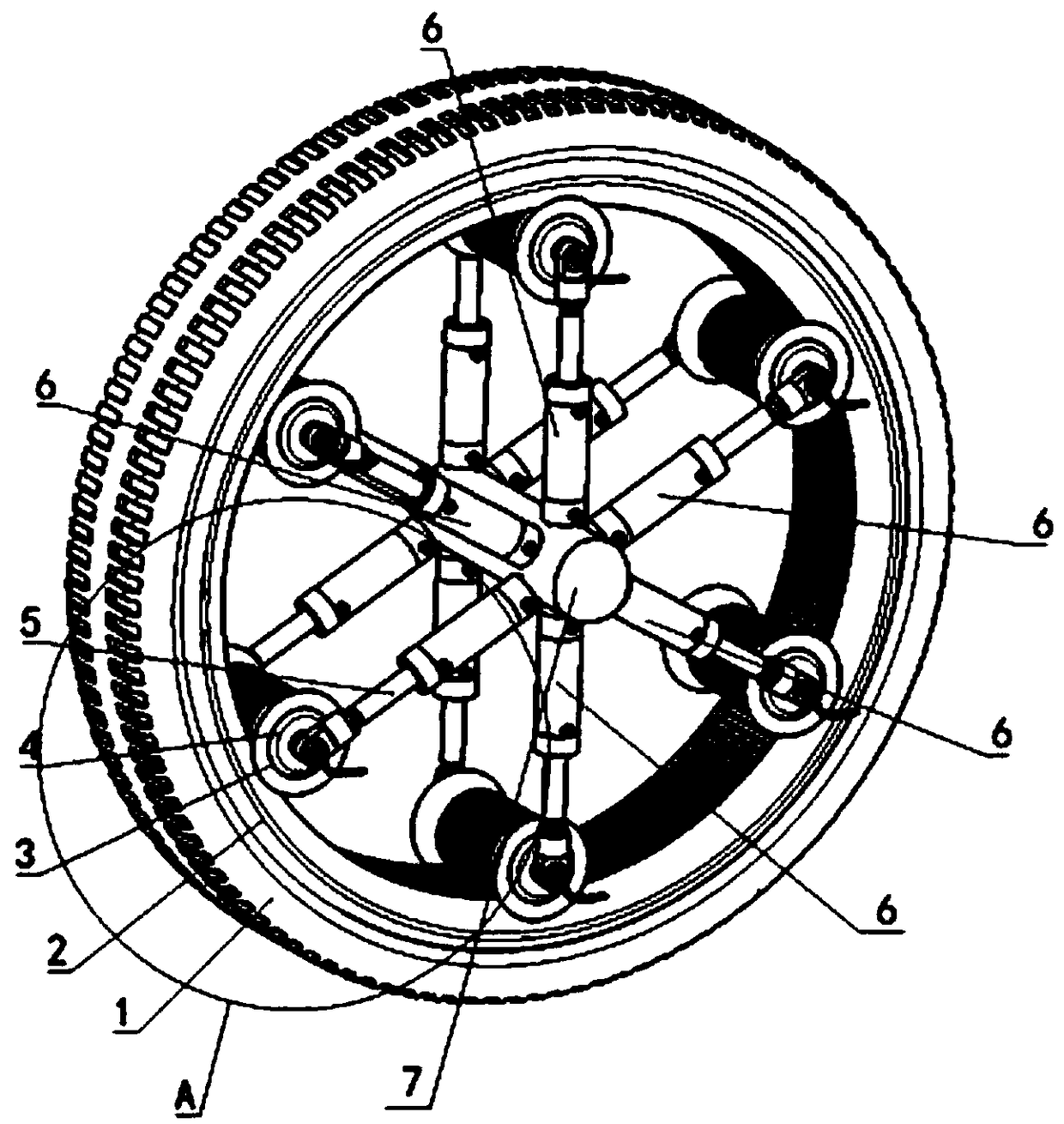

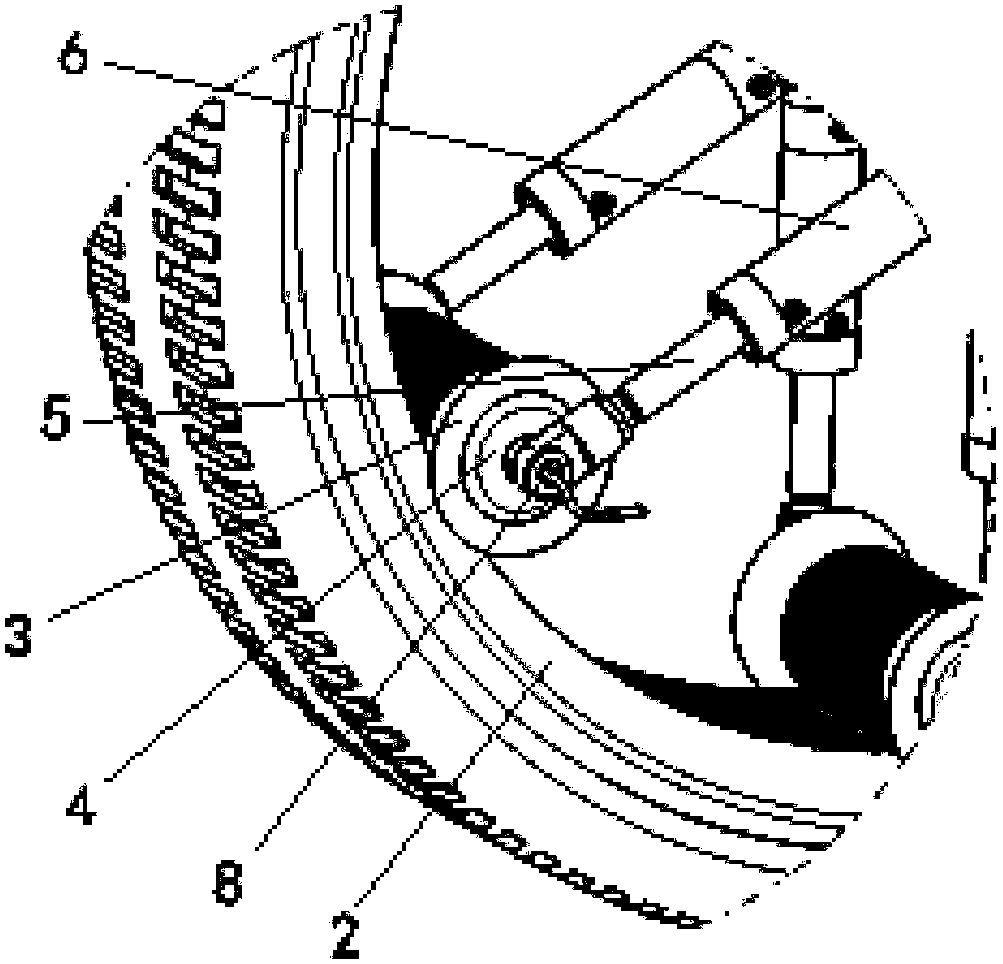

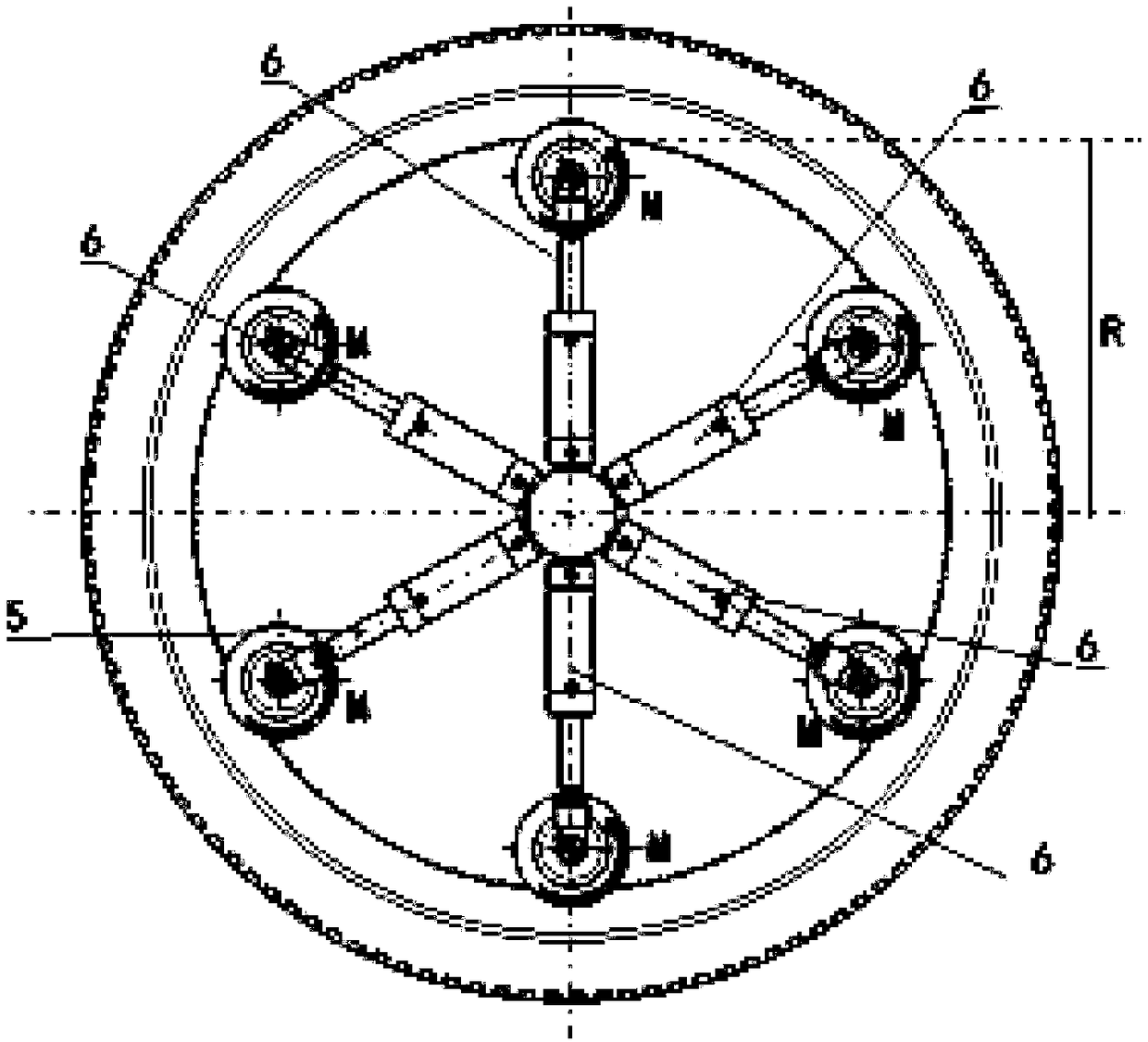

[0032] The working principle of the present invention is as follows: the drive wheel 3 rotates to drive the wheel rim 2 to rotate by applying a torque through the full-plate motor 4, and the supporting system and the central shaft 7 only perform translational motion on the inner plane of the wheel rim, and do not rotate with the rotation of the wheel. The support system is mainly composed of six pairs of hydraulic cylinders, of which 2 pairs of hydraulic cylinders 6 are installed vertically, and the other 4 pairs of hydraulic cylinders are installed at intervals of 60 degrees along the circumference of the central axis. When the central axis needs to be raised, the control strategy is used to control the hydraulic pump to control the input and output hydraulic pressure of the six pairs of hydraulic cylinders. The upper three pairs of hydraulic cylinders 6 perform contraction movement, and the lower three pairs of hydraulic cylinders 6 perform elongation movement. According to th...

Embodiment 2

[0037] refer to Figure 8 , the hydraulic support structure is a hydraulic cylinder and a U-shaped frame 15 fixedly connected with the piston rod 5, the bottom outside of the U-shaped frame 15 is fixedly connected with the piston rod 5, and the structure of two legs of the U-shaped frame 15 Same construction as earrings. The hydraulic support structure is 3 hydraulic cylinders and a U-shaped frame 15 fixedly connected with the piston rods of the hydraulic cylinders, and the structure of the two legs of the U-shaped frame 15 is the same as that of the earrings.

[0038] Connecting the central axis of the variable axle height wheel of the present invention to the axle of the automobile can adjust the chassis height of the vehicle more conveniently, pass obstacles ahead smoothly, and do not need to detour and change lanes, which is different from traditional fixed At the same time, the driving mechanism is installed on the inside of the wheel, which is different from traditional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com