Screening cleaning equipment for desert waste

A technology for cleaning equipment and garbage, applied in the fields of filter screen, cleaning method, road surface cleaning, etc., can solve the problems of affecting the sanitation of tourist deserts, unable to clean sanitary equipment, destroying the natural beauty of deserts, etc., achieving simple structure, easy disassembly and replacement, Good screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

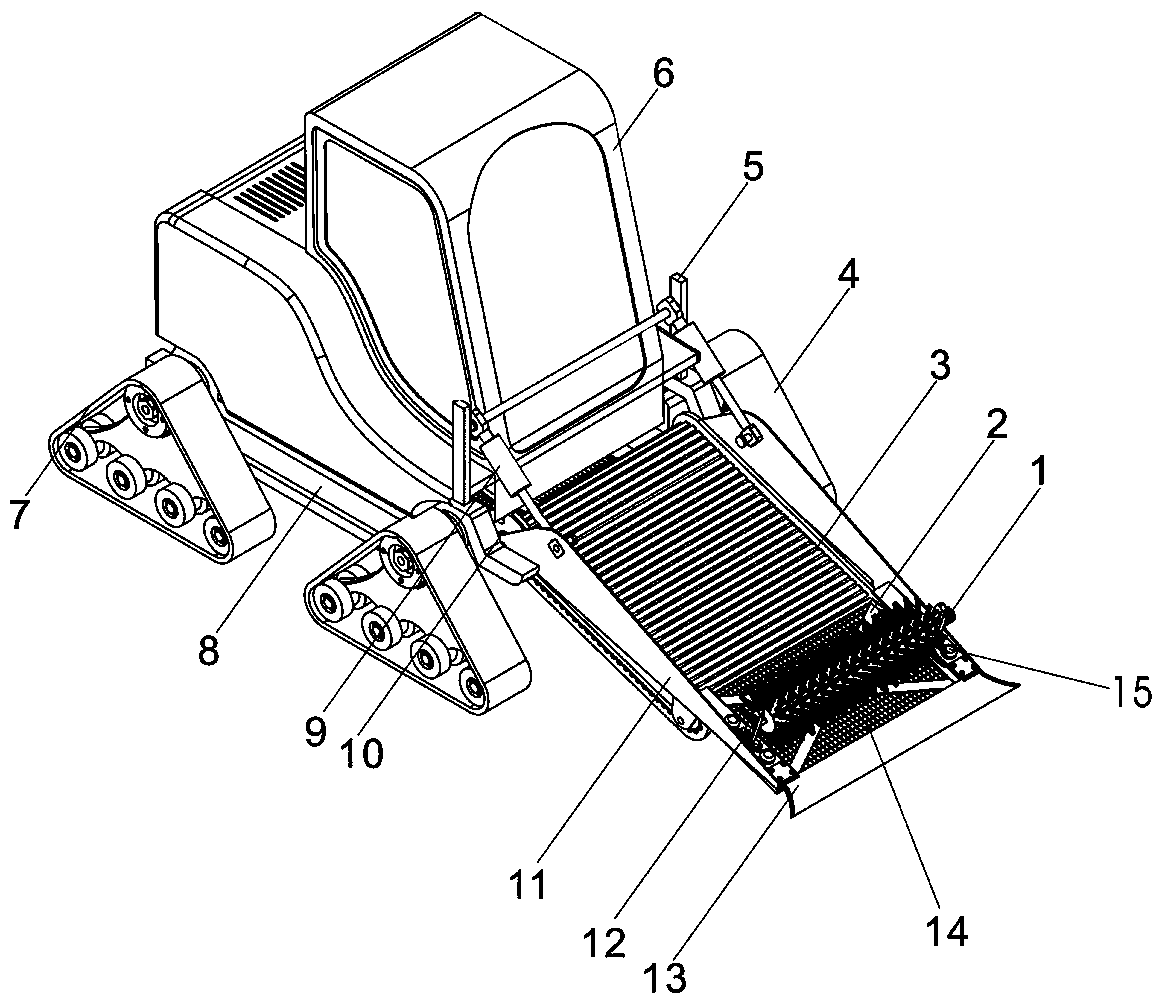

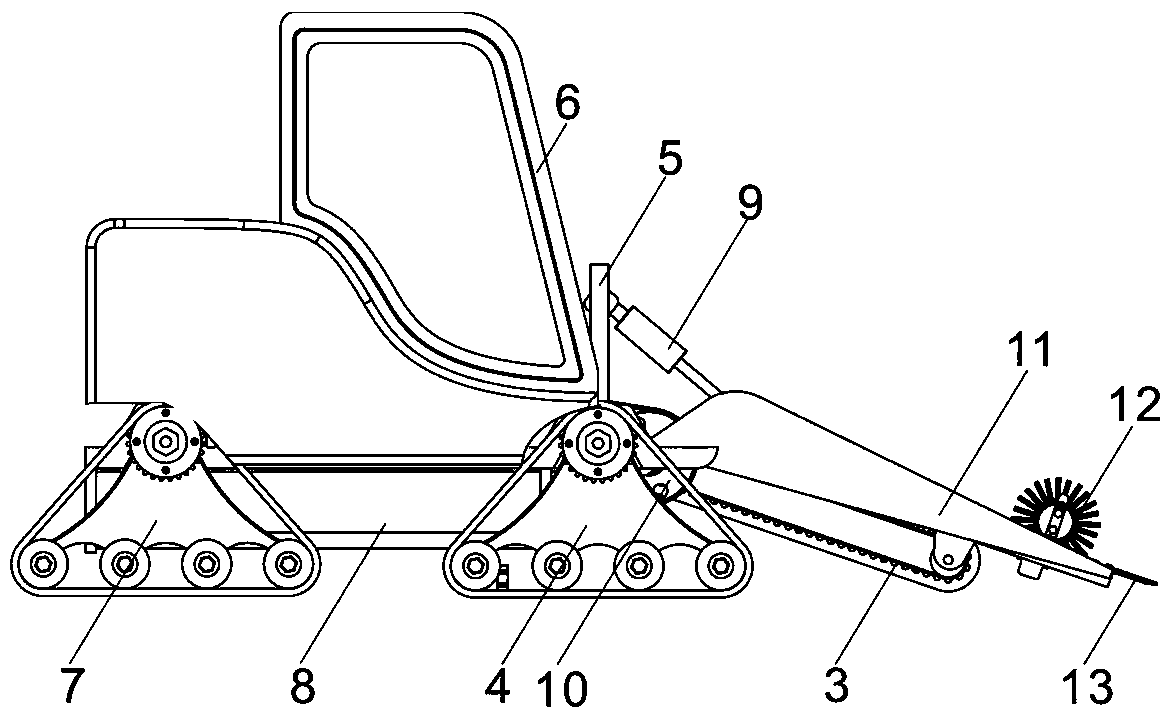

Embodiment 1

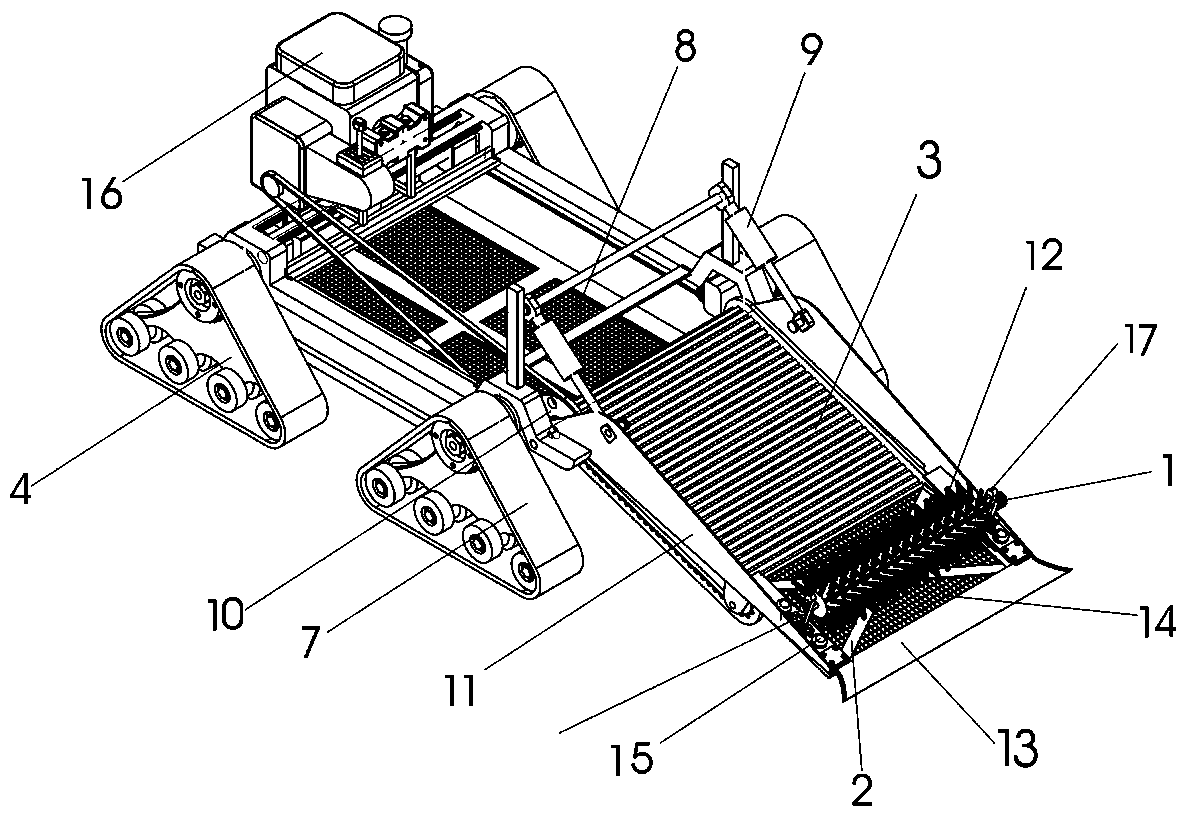

[0018] The other structures of the present embodiment are as described above, the mechanical power of the engine 16 is mainly used for walking, the rotation of the garbage conveyor belt 3 and hydraulic power, etc., and the vibration of the screen and the power of the rolling sweep motor come from the electric power of the rechargeable bottle.

Embodiment 2

[0020] Such as Figure 11 , Figure 12 As shown, the rotational force of the rolling brush 12 and the vibratory power of the vibrating screen 14 are all derived from the mechanical power output by the engine. The specific embodiment is that the garbage conveyor belt driving wheel 10 drives the rolling sweep sprocket mechanism 21 to rotate the rolling sweeping brush 12; the outer end of the garbage conveyor belt driven wheel shaft 22 is equipped with an eccentric wheel 23 to drive the crank rocker mechanism 24, so that the screen mesh vibrates Rod 25 drives the vibrating screen to vibrate.

[0021] The working process of the present invention is: during operation, insert the shovel head 13 into the sand and push forward, the sand enters the screen 14 through the shovel 13, and the garbage and sand are separated through vibration, while the garbage left on the screen 13 is continuously accumulated , the accumulated garbage will move upward under the continuous push of the sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com