Turbine rotor welding joint detection system

A technology for steam turbine rotors and welded joints, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of stress distribution changes in welded joints, high welding performance requirements, high welding process and inspection and testing technology requirements, and achieve stable and efficient operation. Avoid the effect of axial play

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

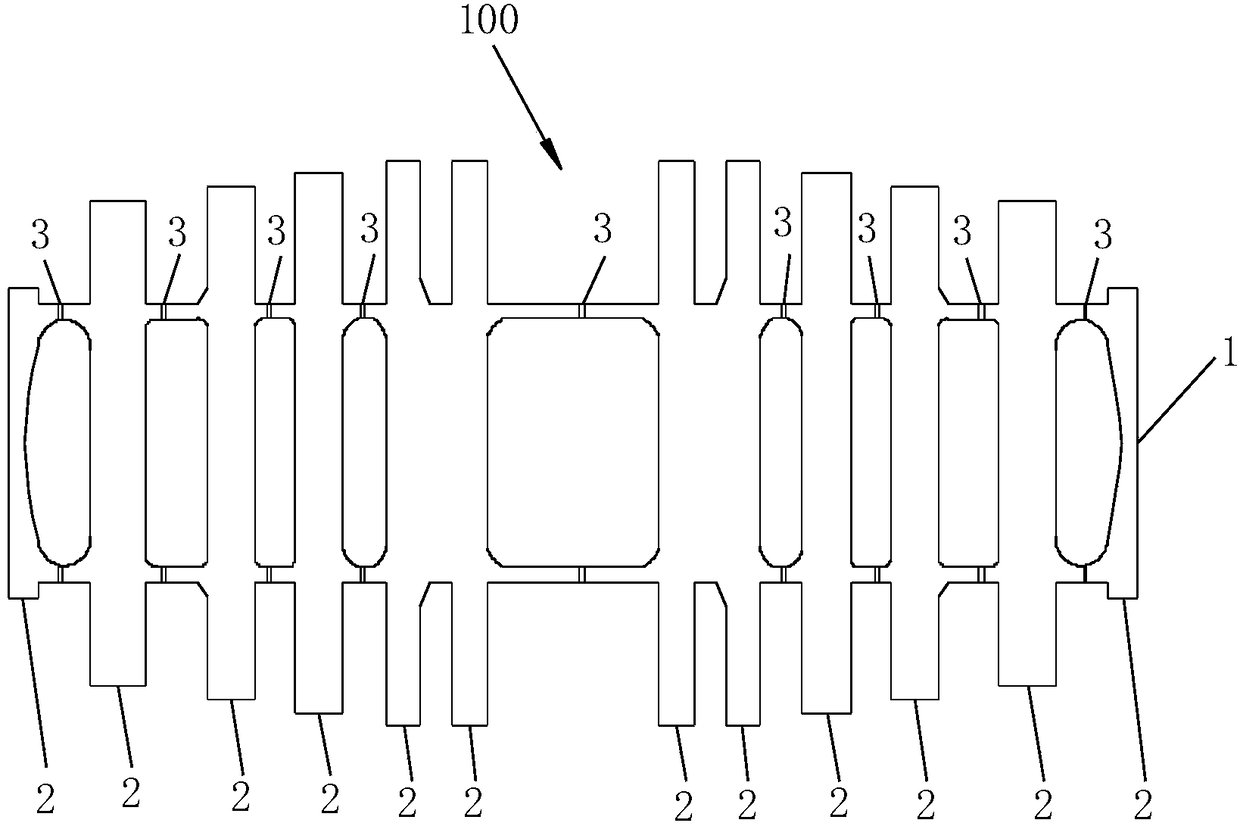

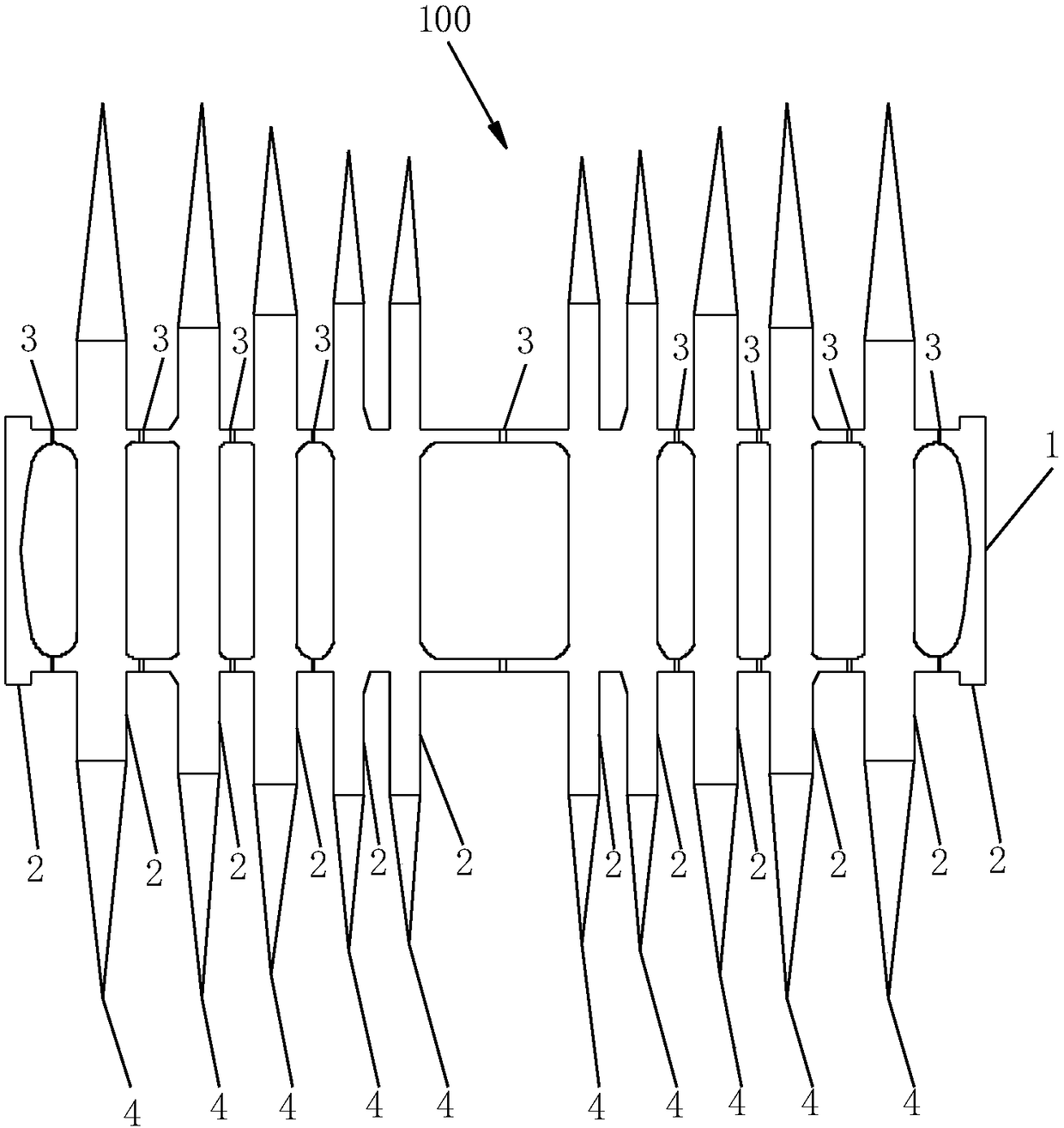

[0033] Such as Figure 1 to Figure 2 As shown, the steam turbine rotor 100 includes a main shaft 1 and a plurality of impellers 2 arranged around the main shaft 1, all the impellers 2 are arranged at intervals along the axial direction of the main shaft 1, and the outermost peripheral portion of each impeller 2 is provided with The radially outwardly extending annular blades 4 of 1, the welded joints 3 of the rotor 100 are annular welds arranged at intervals on the main shaft 1, and the welded joints 3 are located between adjacent impellers 2. The minimum distance between two adjacent impellers 2 is only 200mm, and the circumference of the main shaft 11 is 4-5m.

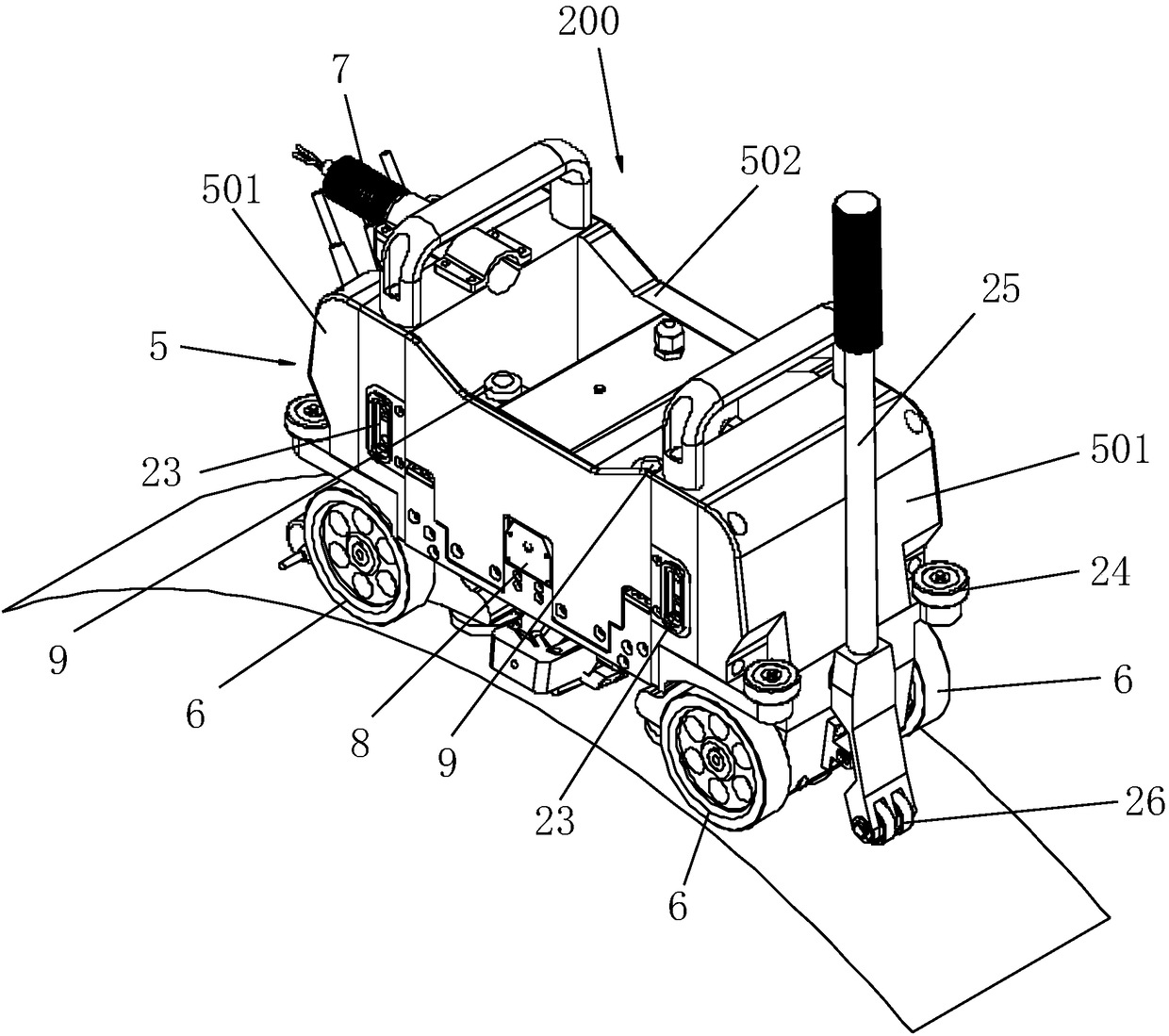

[0034] The detection method of the welded joint 3 includes: using a video detection method to detect surface defects of the welded joint 3; using an array eddy current detection method to det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com