Efficient mechanical vapor recompression (MVR) evaporator with resource recycling function

A technology for recycling resources and evaporators, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve problems such as lack of resource recovery function, high energy consumption, unstable automation control performance, etc., to extend the operating cycle, Reduce cleaning frequency and ensure full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

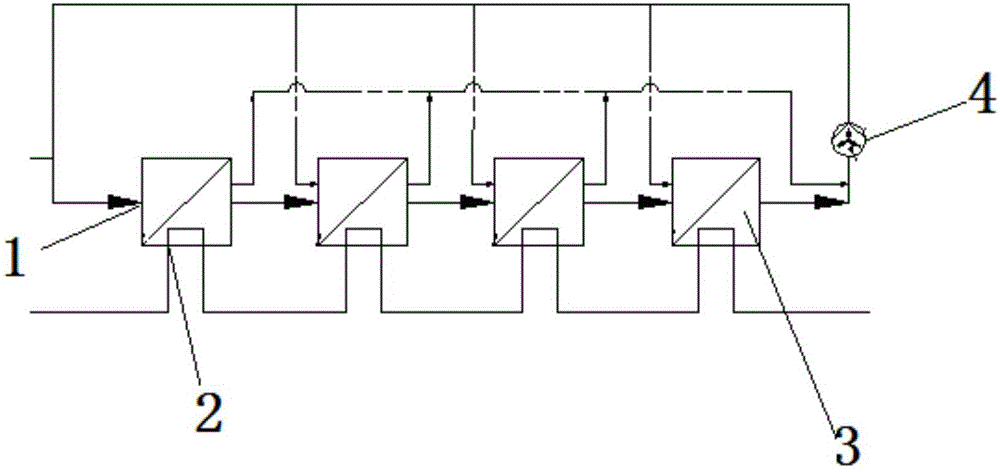

[0036] refer to figure 1 , the MVR high-efficiency evaporator with the function of recycling resources includes at least two evaporator effect bodies 3, each evaporator effect body 3 includes an evaporator body, the evaporator body includes a heater, and a separation chamber connected to the heater, each The evaporator bodies are connected sequentially; the outlet of the separation chamber of the previous evaporator body is connected to the heating steam inlet 1 of the adjacent next evaporator body, and the outlet of the separation chamber of the last evaporator body is connected to the air inlet of a compressor 4 The gas outlet of the compressor 4 is connected to the heating steam inlet 1 of the main body of the evaporator located at the front throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com